10 August, 2001 PM TABLE

5-1

Preventive

Maintenance

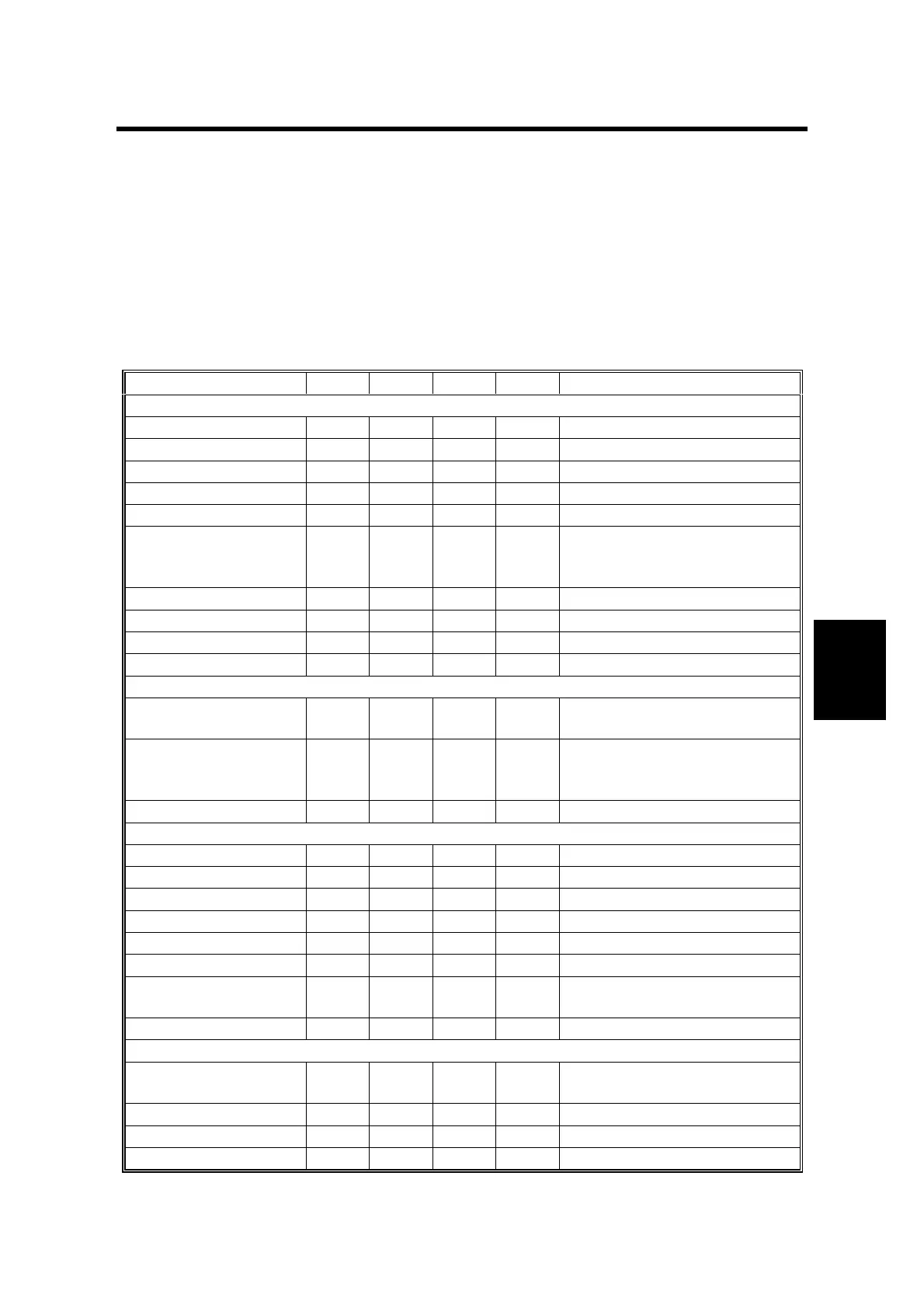

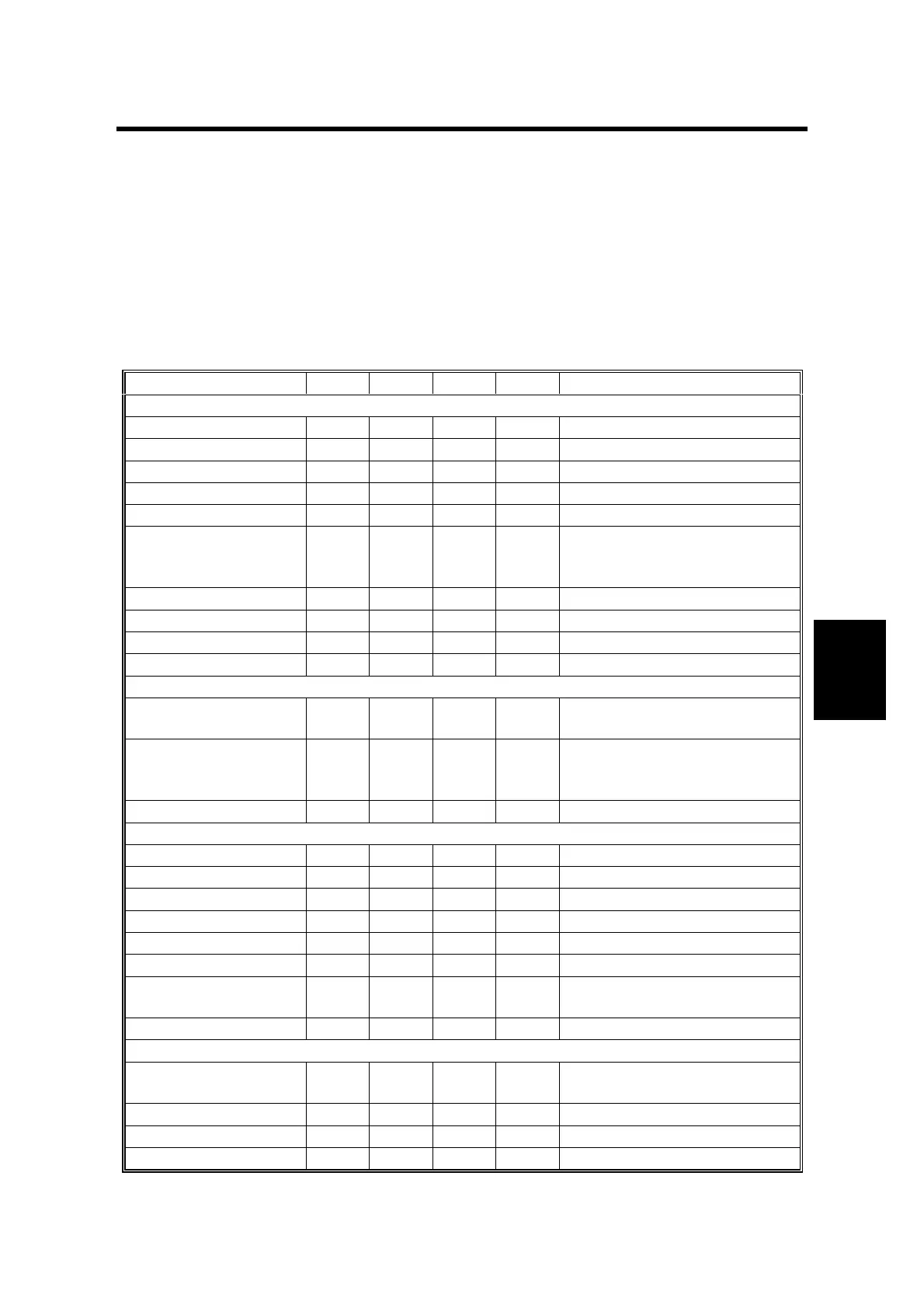

5. PREVENTIVE MAINTENANCE SCHEDULE

5.1 PM TABLE

NOTE: 1) The amounts mentioned as the PM interval indicate the number of

prints.

2) After carrying out PM, clear the maintenance counter (SP7-804).

Symbol key: C: Clean, R: Replace, L: Lubricate, I: Inspect

A265/A267 EM 120K 240K 360K NOTE

SCANNER/LASER OPTICS

Reflector C C C Optics cloth

1st Mirror C C C C Optics cloth

2nd Mirror C C C C Optics cloth

3rd Mirror C C C C Optics cloth

Scanner Guide Rails C C C Do not use alcohol.

Platen Sheet Cover C I I I Replace the platen sheet, if

necessary.

Dry cloth or alcohol

Exposure Glass C C C Dry cloth or alcohol

Toner Shield Glass C C C Optics cloth

APS Sensor C C C Dry cloth or blower brush

AROUND THE DRUM

Transfer/Separation

Unit

RRR

ID Sensor C C C

Perform the ID sensor initial

setting (SP2-935) after

cleaning (blower brush)

PAPER FEED

Registration Rollers C C C C Clean with water

Paper Feed Roller C R R R Clean with water

Friction Pad C R R R Dry cloth

Paper Feed Guides C C C C Clean with alcohol.

Relay Rollers C C C C Clean with water.

Bottom Plate Pad C C C C Clean with water.

Registration Roller

Mylar

C C C C Clean with water.

FUSING UNIT AND PAPER EXIT

Fusing Entrance and

Exit Guide Plates

C C C Clean with water or alcohol.

Hot Roller R R R

Pressure Roller R R R

Fusing Thermistors RRR

Loading...

Loading...