8.4 Vessel shape and dimensions

The de

vice can be congured to suit many common vessel shapes. See Vessel shape (2.5.1)

(Page 123). Whenever possible, use one of the pre-dened selections. If one of the pre-dened

selections is not applicable, a custom volume calculation can be used. (Congure a custom

application by setting parameter "Operation" or "PV selection" to option "Custom", then dene

your vessel shape using Custom (2.6) (Page126).) For more details, see Technical reference

(Page201).

Each vessel shape uses the empty distance value in its calculations of volume. See PV

selection (2.1.1) (Page114) for an illustration.

Some vessel shapes also require extra dimensions to calculate the volume. Do not estimate

these values as they must be exact to ensure the accuracy of your volume calculations.

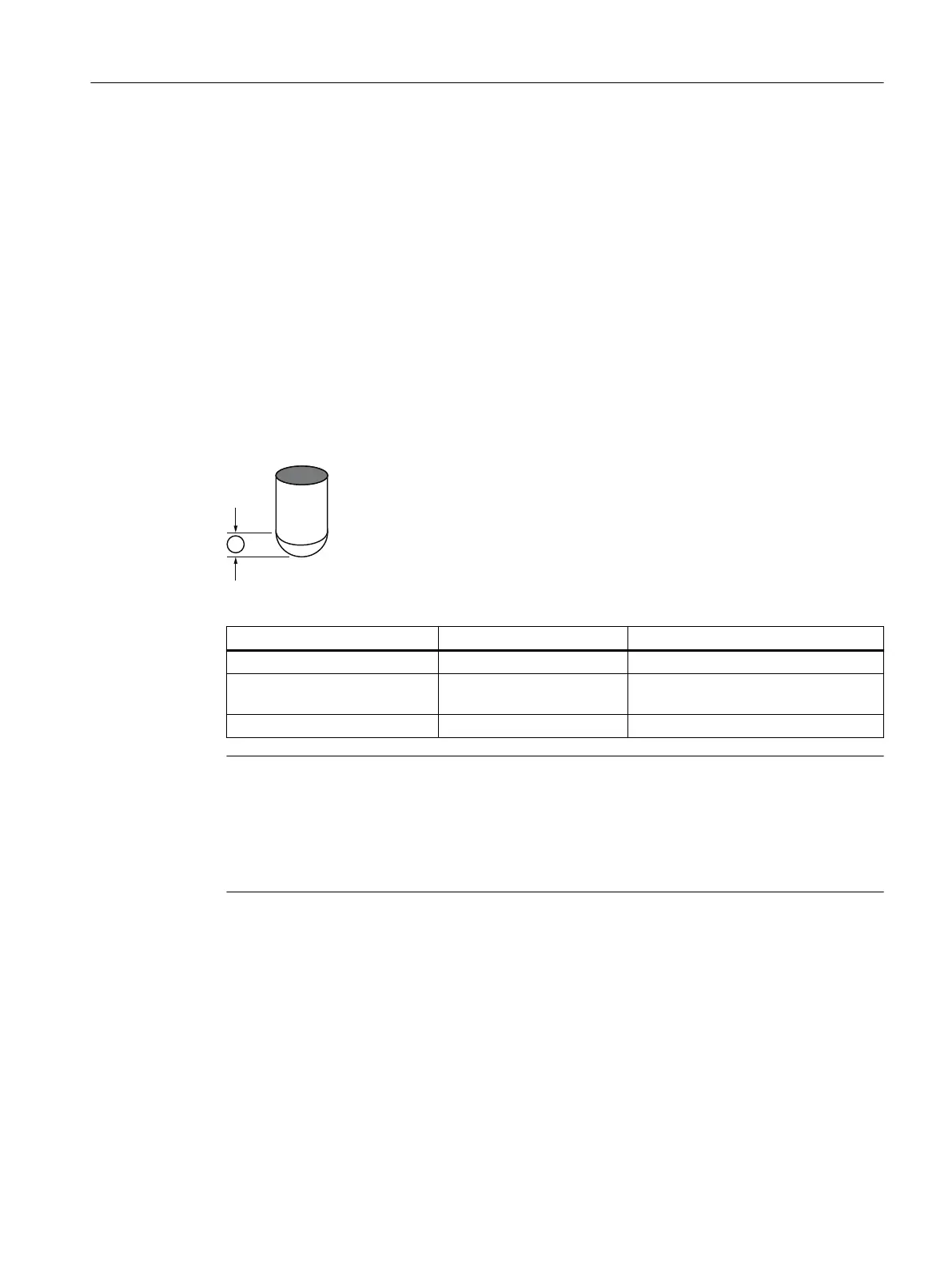

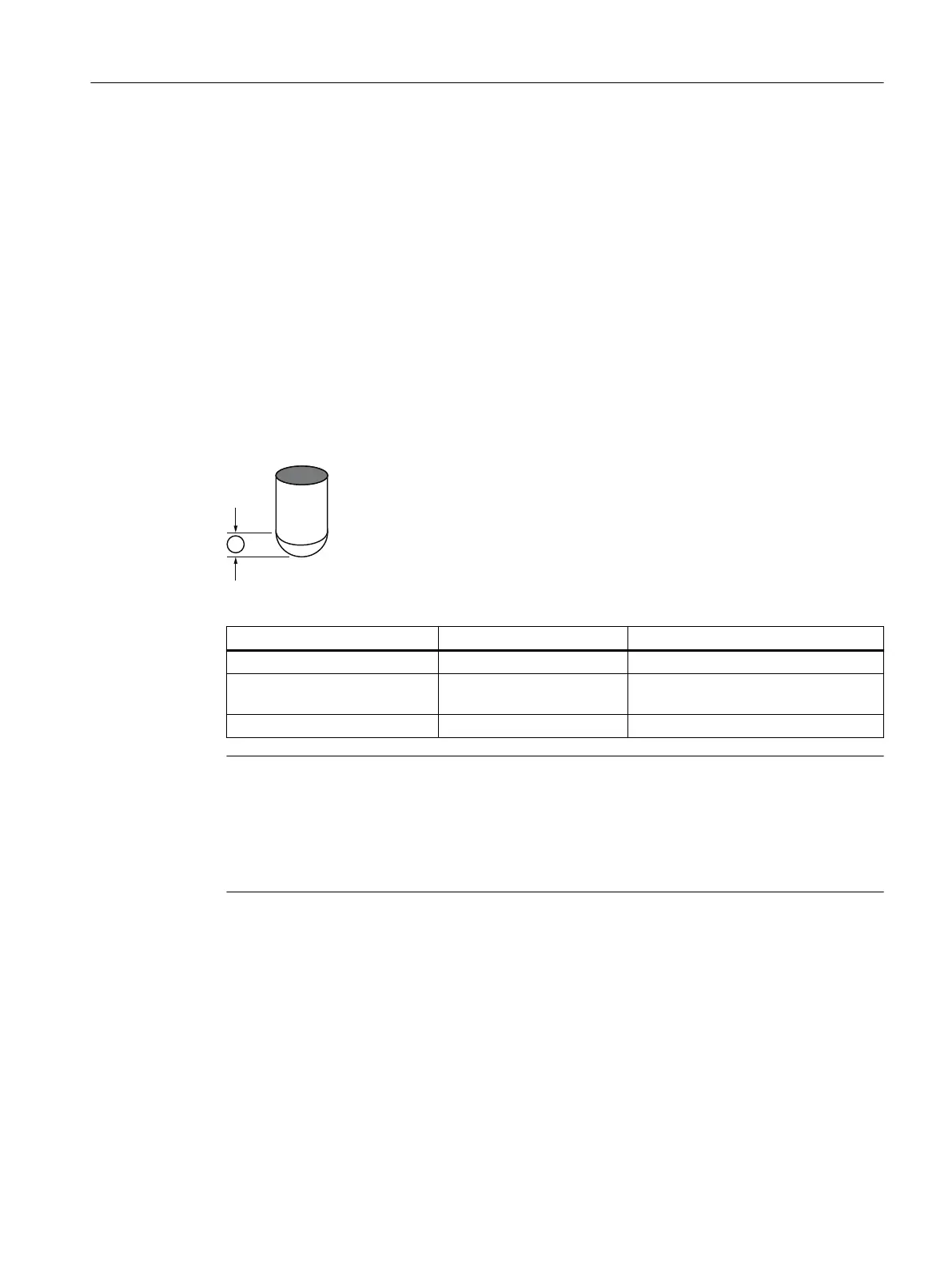

Example:

To congure volume for a vessel with a half-sphere bottom, set the following:

① Vessel dimension A

Parameter Sample value Description

Vessel shape Half sphere bottom vessel Sets correct vessel shape

Upper scaling point 100 Sets upper scaling at 100

(dened in "V

olume units")

Vessel dimension A 1.3 Sets dimension A to 1.3 m

Note

Ex

ample outcome

• The default reading changes to a range from 0 to 100, which is the value in parameter Upper

scaling point (2.5.5) (Page125).

• The process empty value is still measured to the bottom of the vessel (value in parameter

"Lower calibration point"), not the top of dimensionA.

8.5 Simulation

Pr

ocess values, loop current, and diagnostics can be simulated with this device. Distance process

value can be simulated via the HMI, or via an engineering system such as SIMATIC PDM. Process

values and diagnostics can be simulated via a remote engineering system.

Current output simulation

The current output can also be simulated using Loop test (3.8.1) (Page143).

Operating

8.5Simulation

SITRANS LR500 series with mA/HART

Operating Instructions, 03/2024, A5E51099898-AA 89

Loading...

Loading...