4 Mechanical Interface

4.1 Introduction

This chapter describes the basics of mounting the various parts of the robot system. Electrical

installation instructions in chapter 5 must be observed.

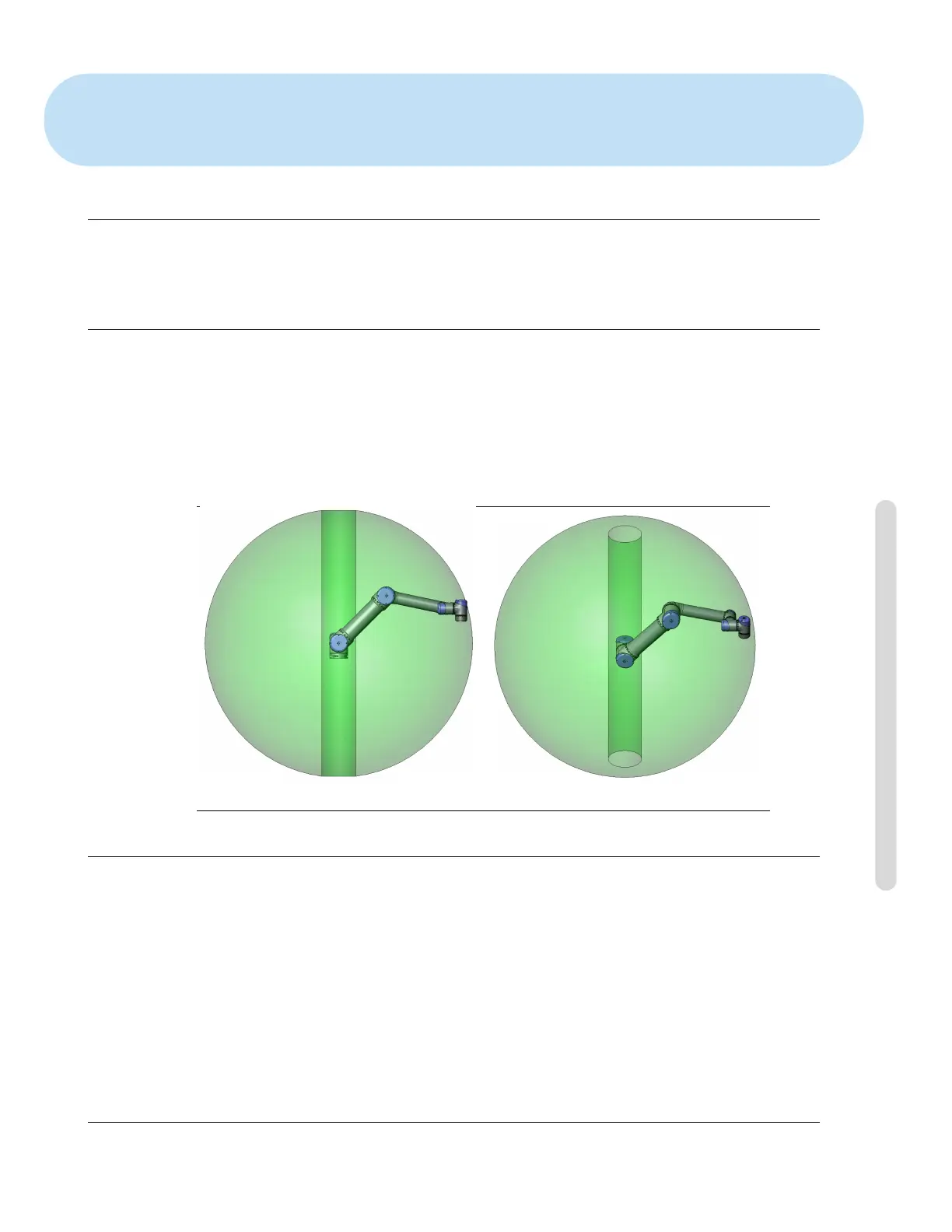

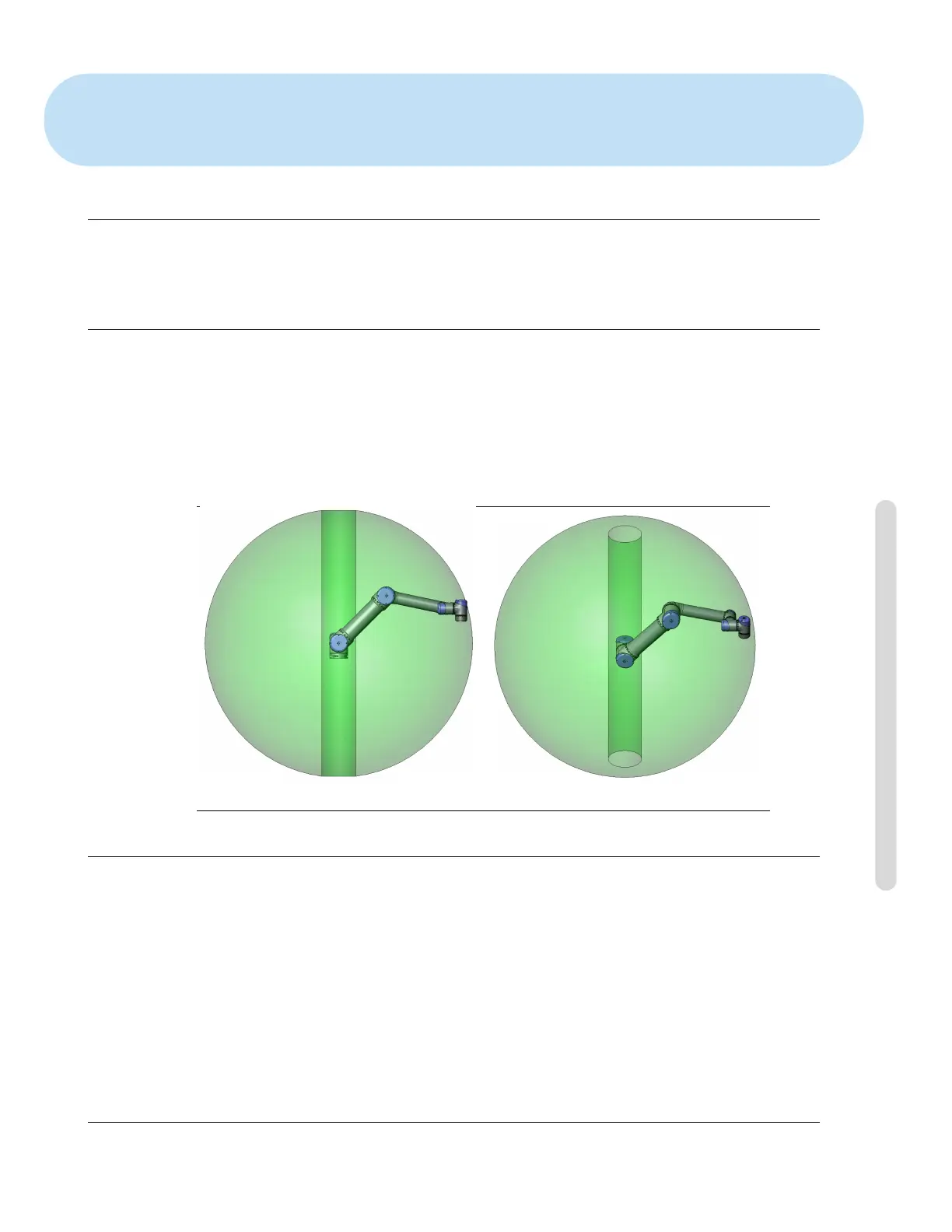

4.2 Workspace of the Robot

The workspace of the UR3 robot extends 500 mm from the base joint. It is important to consider

the cylindrical volume directly above and directly below the robot base when a mounting place for

the robot is chosen. Moving the tool close to the cylindrical volume should be avoided if possible,

because it causes the joints to move fast even though the tool is moving slowly, causing the robot

to work inefficiently and making it difficult to conduct a risk assessment.

Front Tilted

4.3 Mounting

Robot Arm The robot arm is mounted using four M6 bolts, using the four 6.6 mm holes on the

base. It is recommended to tighten these bolts with 9 N m torque. If very accurate repositioning

of the robot arm is desired, two Ø5 holes are provided for use with a pin. Also, an accurate base

counterpart can be purchased as an accessory. Figure 4.1 shows where to drill holes and mount the

screws.

The robot connector cable can be mounted through the side or through the bottom of the base.

Mount the robot on a sturdy surface strong enough to withstand at least ten times the full torque of

the base joint and at least five times the weight of the robot arm. Furthermore the surface shall be

Version 3.10

Copyright © 2009–2019 by Universal Robots A/S. All rights reserved.

I-23 UR3/CB3

Loading...

Loading...