5.3 Controller I/O

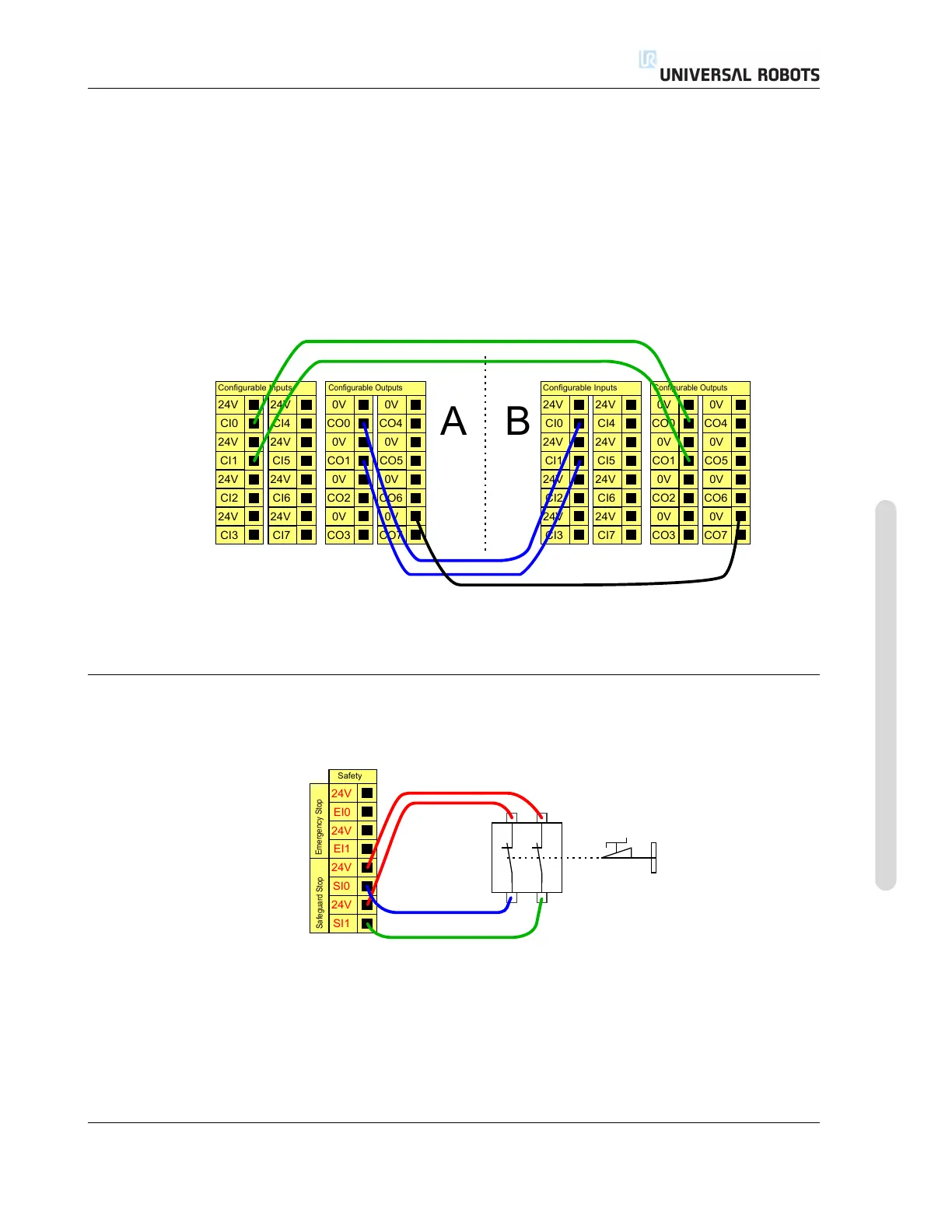

The Robot Emergency Stop input cannot be used for sharing purposes, since both machines will

wait for the each other to go out of the emergency stopped condition.

In order to share the emergency stop function with other machinery, the following configurable

I/O functions must be configured through the GUI.

• Configurable input pair: External emergency stop.

• Configurable output pair: System emergency stop.

The illustration below shows how two UR robots share their emergency stop functions. In this

example the configured I/Os used are “CI0-CI1” and “CO0-CO1”.

24V

CI1

24V

CI2

24V

CI3

24V

CI0

Configurable Inputs

24V

CI5

24V

CI6

24V

CI7

24V

CI4

0V

CO1

0V

CO2

0V

CO3

0V

CO0

Configurable Outputs

0V

CO5

0V

CO6

0V

CO7

0V

CO4

24V

CI1

24V

CI2

24V

CI3

24V

CI0

Configurable Inputs

24V

CI5

24V

CI6

24V

CI7

24V

CI4

0V

CO1

0V

CO2

0V

CO3

0V

CO0

Configurable Outputs

0V

CO5

0V

CO6

0V

CO7

0V

CO4

A

B

If more than two UR robots or other machines need to be connected, a safety PLC is needed to

control the emergency stop signals.

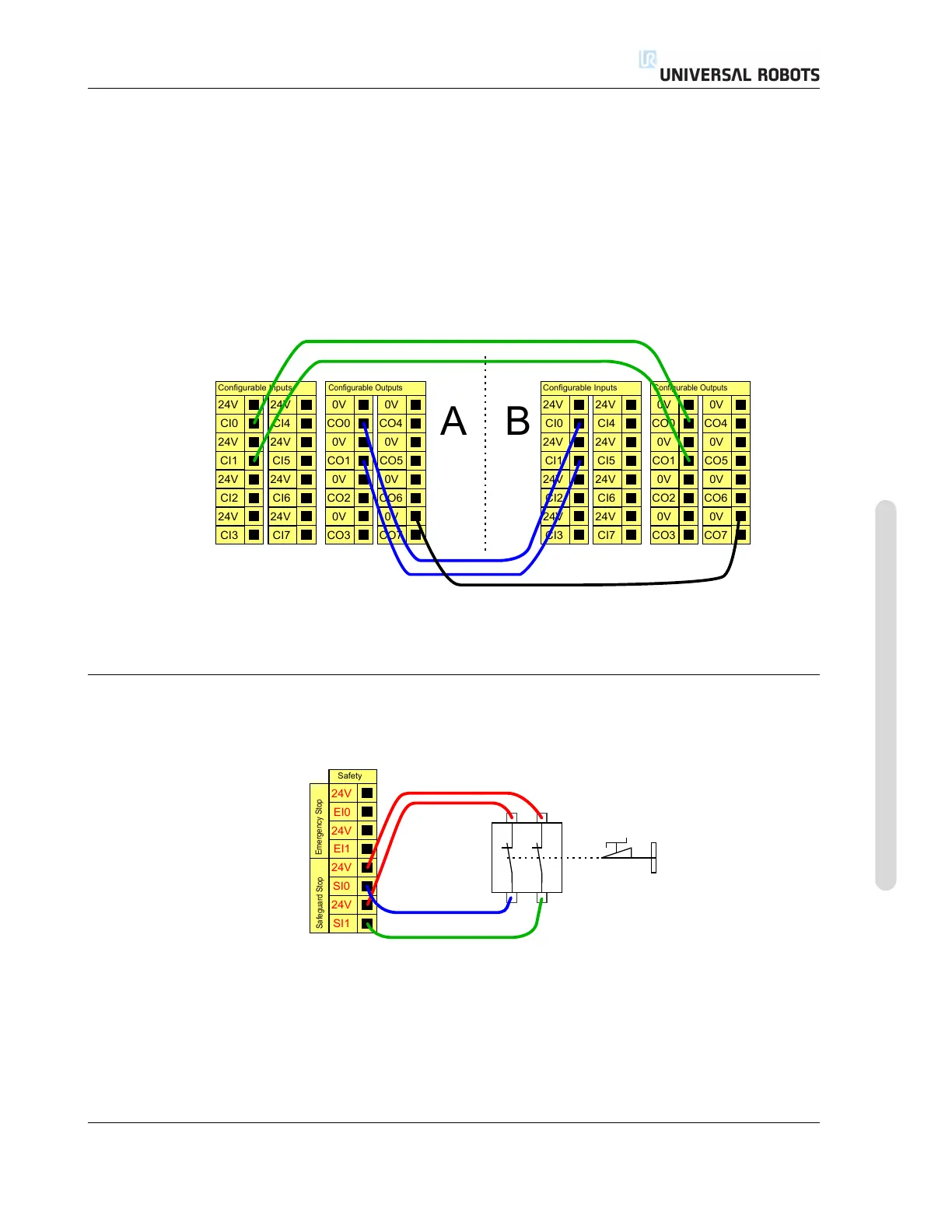

5.3.2.4 Safeguard stop with automatic resume

An example of a basic safeguard stop device is a door switch where the robot is stopped when a

door is opened, see illustration below.

24V

EI1

24V

SI0

24V

SI1

24V

EI0

Safety

Safeguard Stop

Emergency Stop

This configuration is only intended for application where the operator cannot pass the door and

close it behind him. The configurable I/O can be used to setup a reset button outside the door, to

reactivate robot motion.

Another example where automatic resume can be appropriate is when using a safety mat or a

safety-related laser scanner, see below.

Version 3.10

Copyright © 2009–2019 by Universal Robots A/S. All rights reserved.

I-35 UR3/CB3

Loading...

Loading...