5.3 Controller I/O

Note: *For resistive loads or inductive loads of maximum 1H.

NOTE:

The word configurable is used for I/O that can be configured as ei-

ther safety-related I/O or normal I/O. These are the yellow terminals

with black text.

5.3.2 Safety I/O

This section describes the dedicated safety inputs (Yellow terminal with red text) and the config-

urable I/O (Yellow terminals with black text) when configured as safety I/O. The common specifi-

cations in section 5.3.1 must be observed.

Safety devices and equipment must be installed according to the safety instructions and the risk

assessment (see chapter 1).

All safety I/O are pairwise (redundant) and must be kept as two separate branches. A single fault

shall not cause loss of the safety function.

The two permanent safety inputs are the Robot Emergency Stop and the Safeguard Stop.

The Robot Emergency Stop input is for emergency stop equipment only. The Safeguard Stop input

is for all kinds of safety-related protective equipment. The functional difference is shown below.

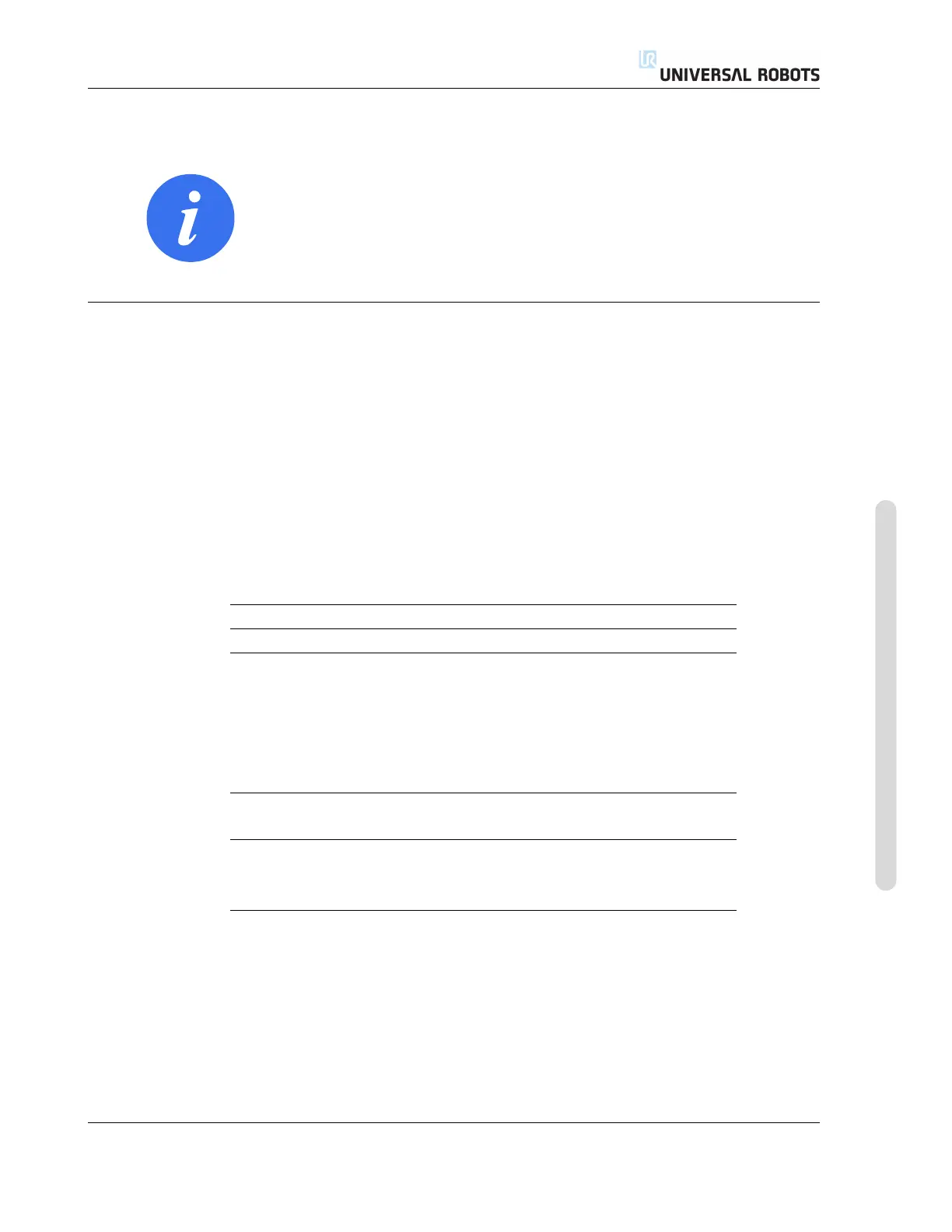

Emergency Stop Safeguard Stop

Robot stops moving Yes Yes

Program execution Stops Pauses

Robot power Off On

Reset Manual Automatic or manual

Frequency of use Infrequent Every cycle to infrequent

Requires re-

initialization

Brake release only No

Stop Category

(IEC 60204-1)

1 2

Performance level of

monitoring function

(ISO 13849-1)

PLd PLd

It is possible to use the configurable I/O to set up additional safety I/O functionality, e.g. emer-

gency stop output. Configuring a set of configurable I/O for safety functions are done through the

GUI, see part II.

Some examples of how to use safety I/O are shown in the following subsections.

Version 3.10

Copyright © 2009–2019 by Universal Robots A/S. All rights reserved.

I-33 UR3/CB3

Loading...

Loading...