© Cesab 16 – 10 T Code(s): 841, 842, 843

Repair manual: Mast C7000 Model(s): S210, S212, S212S, S212L, S214, S214L, S220D

Publication Number: 7588857-040 Date: 2018-05-01 Applies from serial number: 6384351-

16.3.5 Lubrication

Both mineral and synthetic oils can be used to lubricate Rexnord chains.

Note:

Lubricants must not

contain substances such as molybdenum disulphide,

PTFE or such.

The weight of the fork carriage should be offloaded from the

lifting chain (hanging free) when the chain is lubricated.

• Lubrication intervals:

- 500 hours with normal operations

- 100 hours when operating in rugged environments such as cold stores

and corrosive environments.

The chains are sprayed with lubricant. Please note that the entire chain must

be lubricated, even the fastening bolts. It is particularly important that the part

of the chain that runs over the chain wheel is well lubricated.

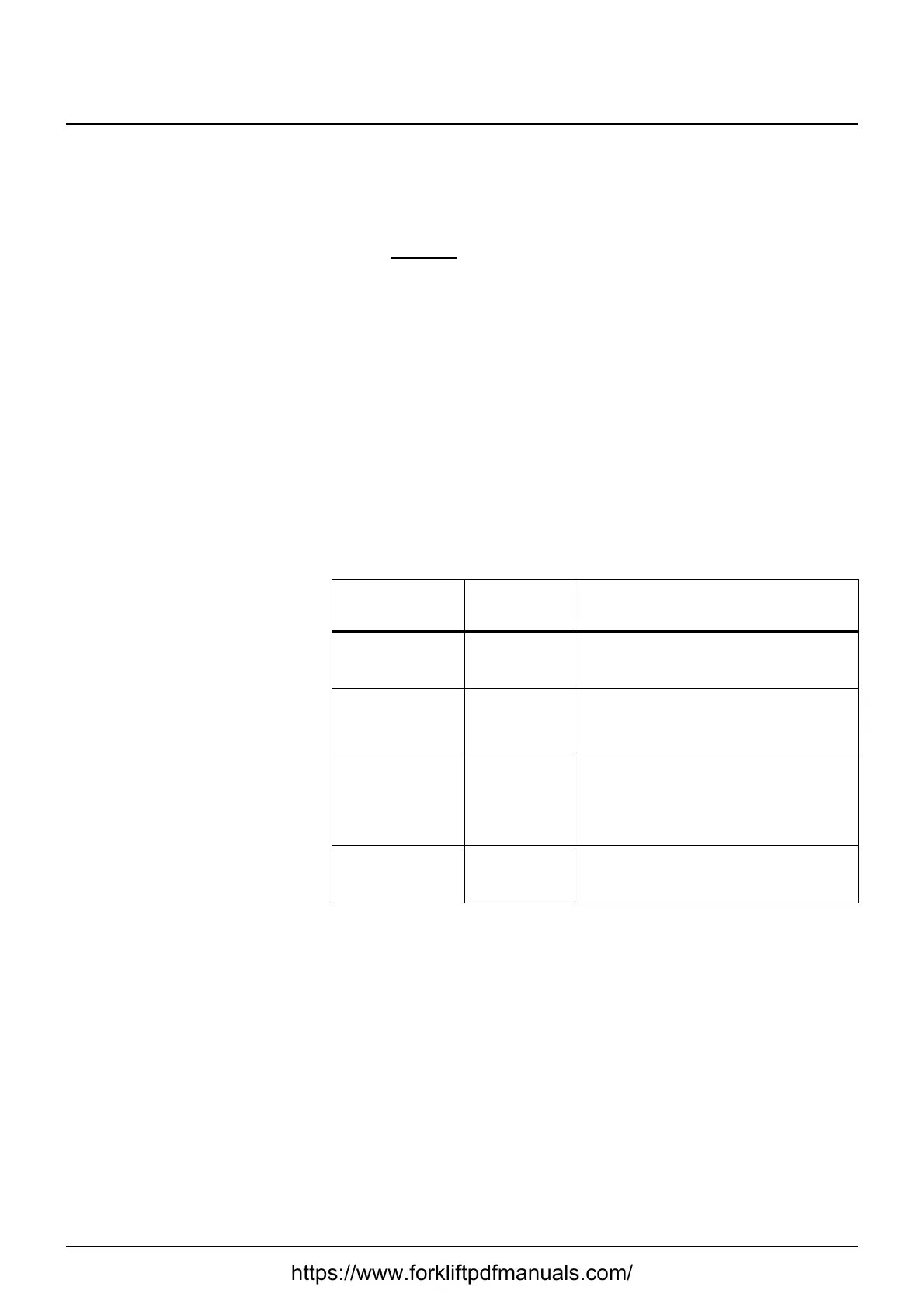

The lubricate must comply with the viscosity demands at respective

temperatures as set out in the table below. The following lubricants are

recommended:

* Similar products from other manufacturers may be used.

Note:

Do not use any special rustproofing agents to prevent

corrosion of the lifting chains.

These agents impair lubrication of the chains. Regular lubrication is the

best method to prevent rusting.

Ambient

temperature

Viscosity

class

Recommended products*

> - 40

°

C

< - 30

°

C

VG 15 Klüberoil 4UH 1-15, Klüber

Lubrication

> - 30

°

C

< + 5

°

C

VG 68 Klüberoil 4UH 1-68N, Klüber

Lubrication

Anticorit LBO 160 TT, Fuchs DEA

> + 5

°

C

< +45

°

C

VG 150 Klüberoil 4UH 1-150N, Klüber

Lubrication

Anticorit LBO 160, Fuchs DEA

Rexoil, Rexnord Kette

>+ 45

°

C

<+ 80

°

C

VG 220 Klüberoil 4UH 1-220N, Klüber

Lubrication

https://www.forkliftpdfmanuals.com/

Loading...

Loading...