CGCOMMUNICATIONS GUIDE PROFIBUS-DP COMMUNICATIONS

369 MOTOR MANAGEMENT RELAY – COMMUNICATIONS GUIDE CG9

2.4 369 Relay Profibus-DP Diagnostics

The 369 Motor Management Relay supports both slave mandatory (6 bytes system-wide

standardized) and slave specific diagnostic data. If the diagnostics are considered high

priority, the PLC/host program will be informed of the fault (alarm or trip) and can call a

special error routine.

Diagnostic bytes 1 through 6 represent standard diagnostic data and are formatted as

follows.

The extended diagnosis for the relay is composed of 26 bytes (bytes 7 to 32) and contains

diagnostic information according to the following table.

202 Last pre–trip Vca 2 0 0000 65000 FDE8 1 V F1 0

204 Last pre–trip Van 2 0 0000 65000 FDE8 1 V F1 0

206 Last pre–trip Vbn 2 0 0000 65000 FDE8 1 V F1 0

208 Last pre–trip Vcn 2 0 0000 65000 FDE8 1 V F1 0

210 Last pre–trip Frequency 2 0 0000 12000 2EE0 1 Hz F3 0

212 Last pre–trip KiloWatts 2

–

32000

8300 32000 7D00 1 kW F4 0

214 Last pre–trip KiloVAR 2

–

32000

8300 32000 7D00 1 kvar F4 0

216 Last pre–trip KiloVA 2 0 0000 50000 C350 1 kVA F1 0

218 Last pre–trip PowerFactor 2 –99 FF9D 100 0064 1 – F21 0

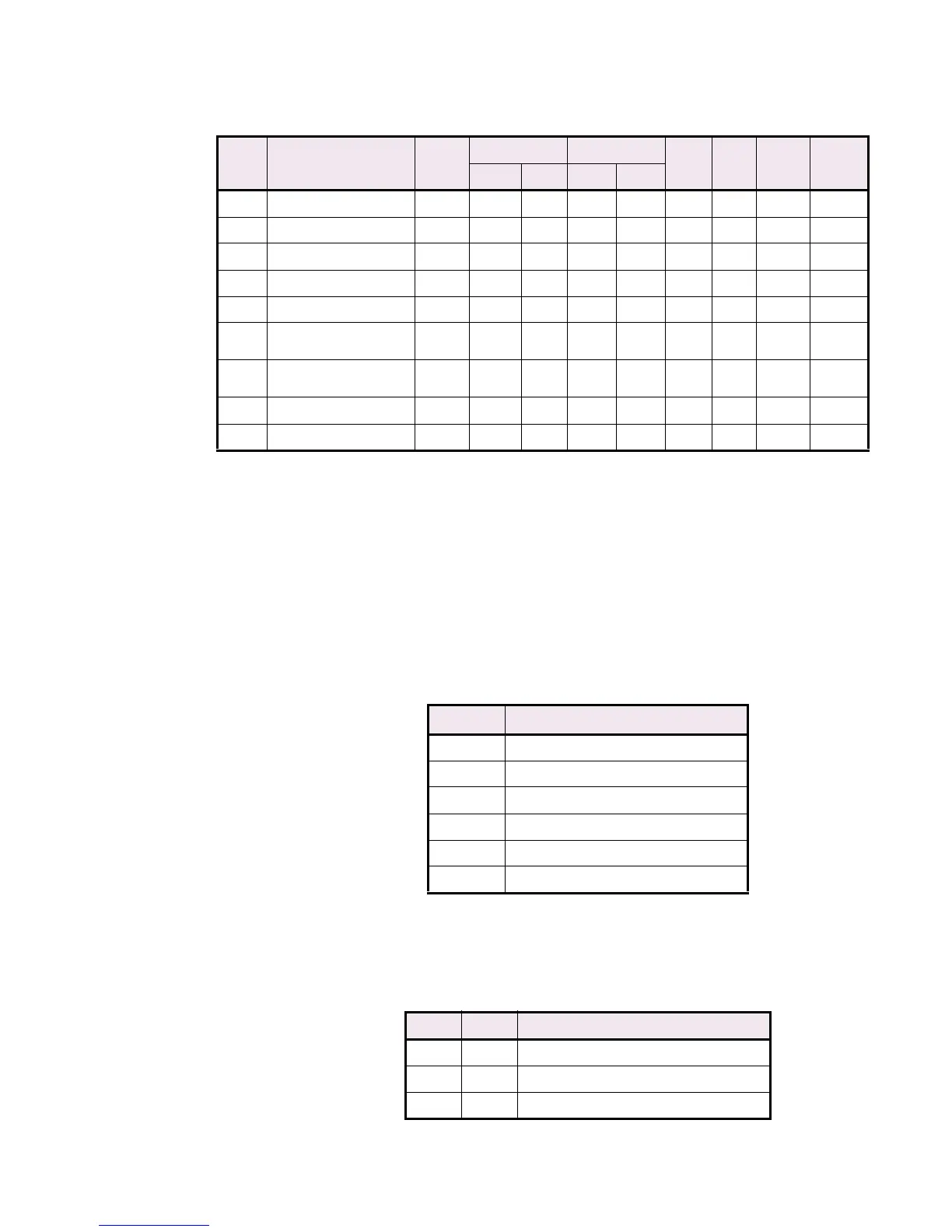

Table CG–1: Profibus Input Data (Sheet 4 of 4)

OFFSET CYCLIC DATA

(ACTUAL VALUES)

LENGTH

(BYTES)

MINIMUM MAXIMUM STEP

VALUE

UNITS FORMAT

CODE

DEFAULT

VALUE HEX VALUE HEX

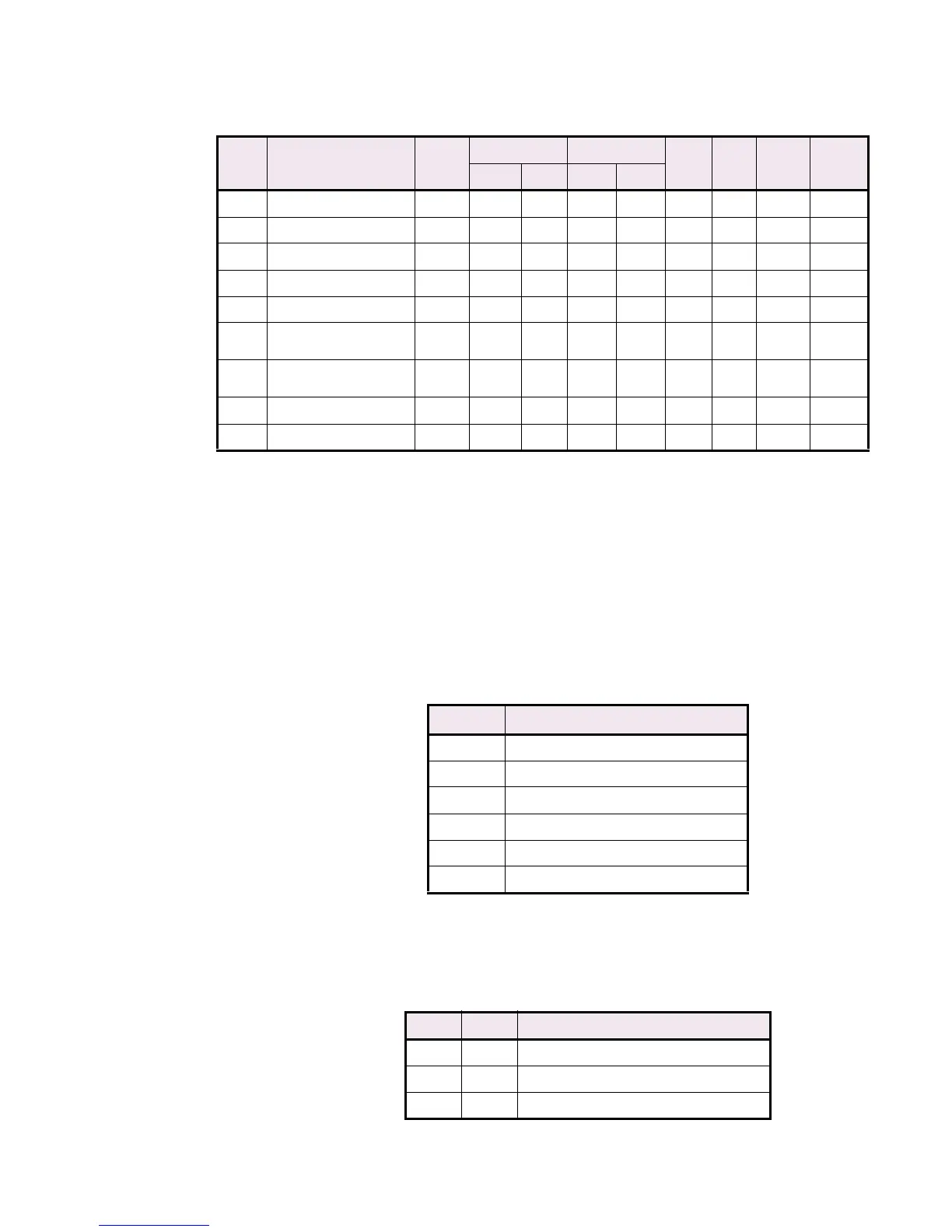

Table CG–2: Diagnostic bytes 1 through 7

BYTE DESCRIPTION

1Station Status 1

2Station Status 2

3Station Status 3

4 Diagnostic Master Address

5 Identification Number (High Byte)

6 Identification Number (Low Byte)

Table CG–3: Profibus Diagnostics (Sheet 1 of 7)

BIT BYTE FUNCTION

0 to 7 7 Number of Diagnostic Bytes

0 8 SinglePhasingTrip

1 8 SpareSwitchTrip

Loading...

Loading...