July 2010 13 – 169

13 Data Backup

13.1 Introduction

Backup

recommended

When servicing it is often necessary or advisable to back up certain control data!

You should always back up the original machine parameters before you make any changes

to the settings of the machine. This can be done on the hard disk of the iTNC 530 without

having to transfer data to an external medium.

--> See ”Create copy of original MP file” on page 30 – 574.

Moreover, all PLC data, i.e. the specific machine data determined by the manufacturer, are of

priority interest for service technicians.

Data backup

Available

data interfaces

The machine data for the factory default condition of the machine tool are often

enclosed with the machine (e.g. on CD-ROM, DVD, USB flash drive) or can be obtained from

the machine tool builder.

If permanent changes were made to the machine (e.g., NC software update,

modifications, etc.) that result in changes or adaptations of the machine data (machine

parameters, PLC program, etc.), a new backup must be created for this machine!

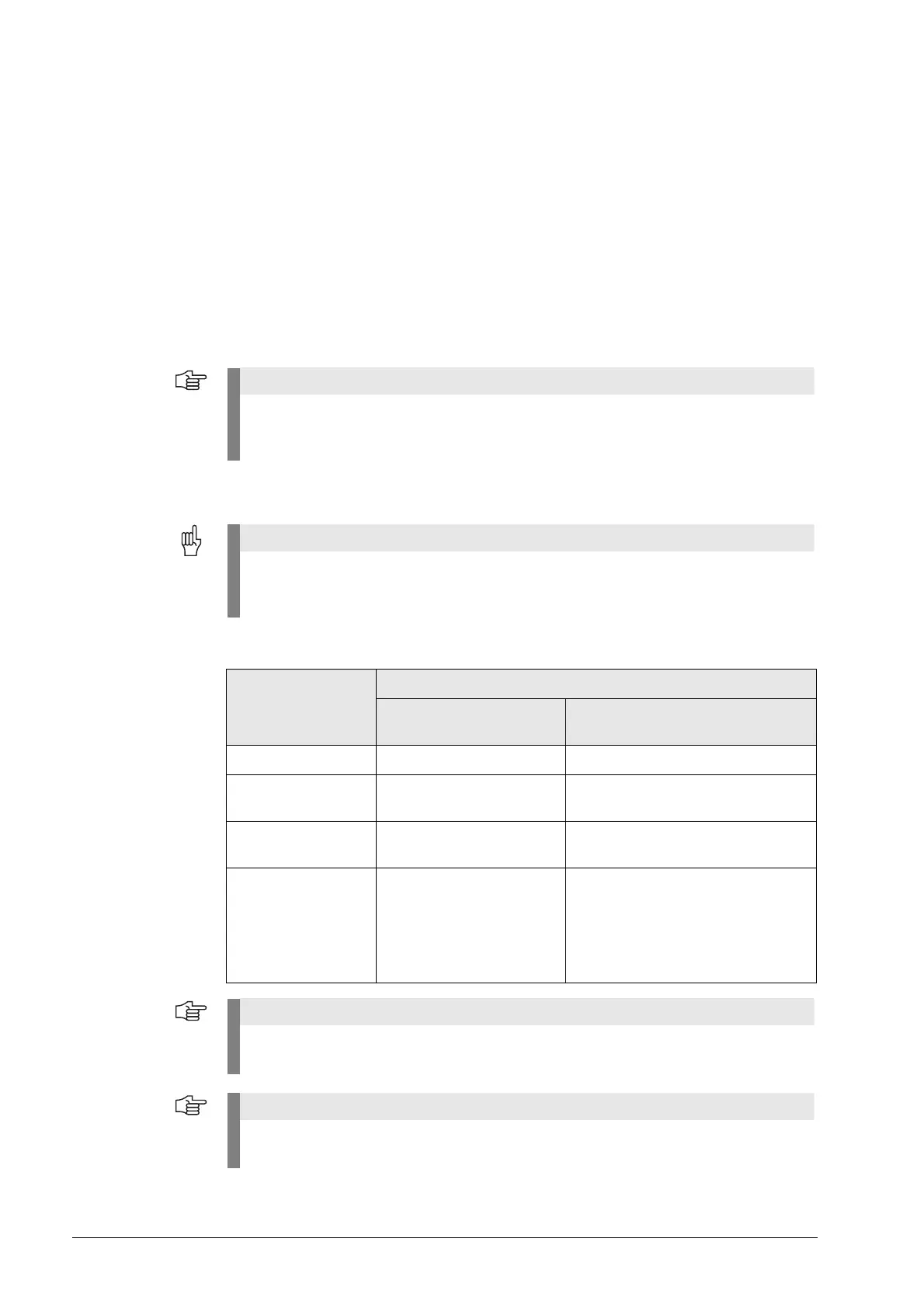

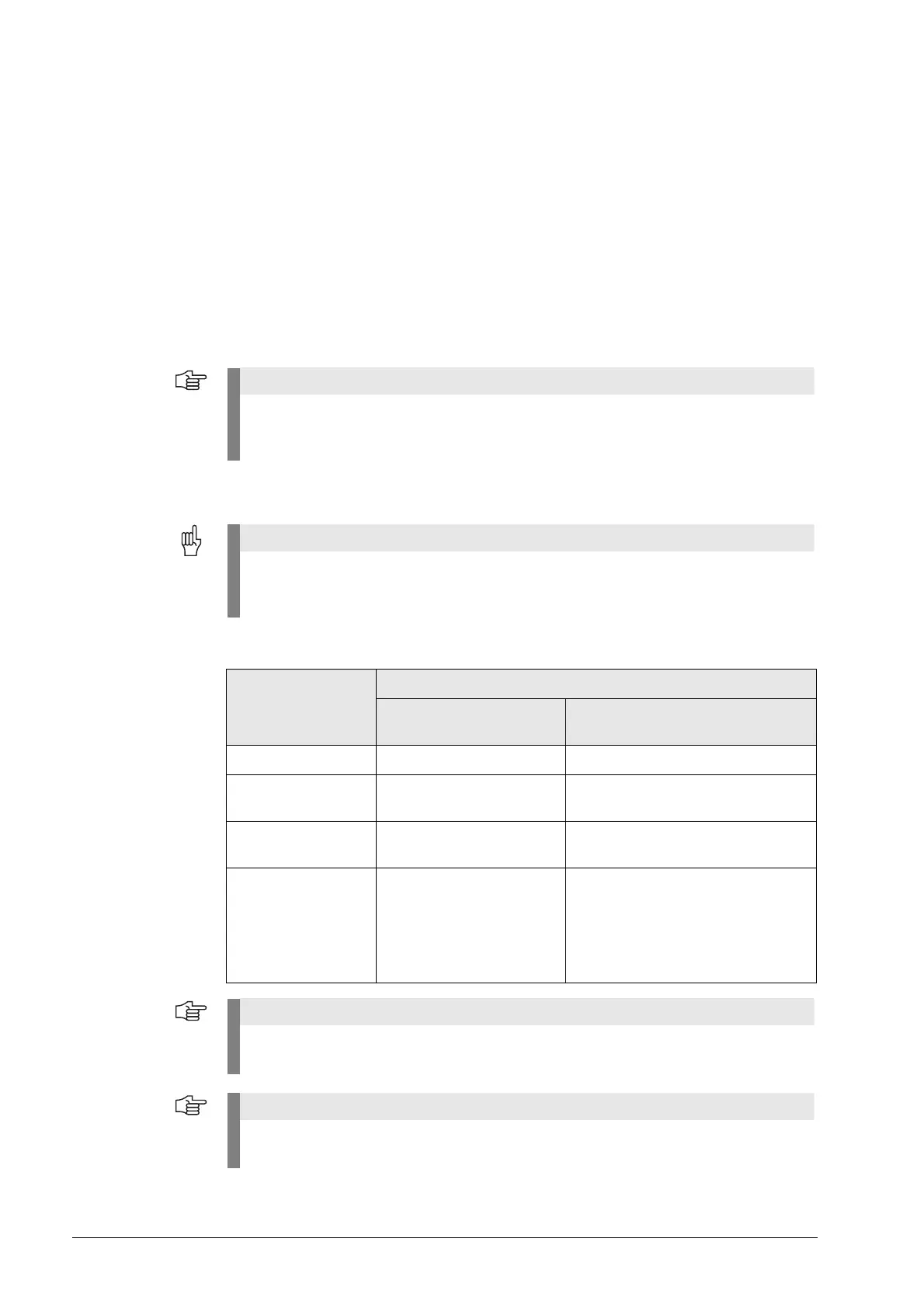

Data interface Connector

Single-processor

software

Dual-processor software

Ethernet X26 (managed by HeROS) X26 (managed by HeROS)

RS-232-C (V.24) X27 for HeROS X27 for Windows

X127 for HeROS

RS-422 (V.11) X28 for HeROS X28 for Windows

X128 for HeROS

USB

(Universal Serial Bus)

X141 and X142

Exception:

MC 420, only X141

X141 and X142

Exception:

MC 422C with X141, X142, X143,

X144

(X144 is located on the bottom of the

housing)

For creating backups with TNCremoNT, the use of the Ethernet interface is advisable. It is

always integrated in the iTNC 530 and represents the fastest mode of data transfer.

Individual or several files and directories can quickly be read in and out with a USB stick

without any large effort.

Loading...

Loading...