July 2010 19 – 317

19 Reference Run

19.1 Definition

The position value (the coordinates) of an axis position is defined with respect to a freely

selectable datum. When the axes are moved, the ACTUAL position is calculated incrementally.

When the machine is switched off, the reference between the axis position and the position

value is lost.

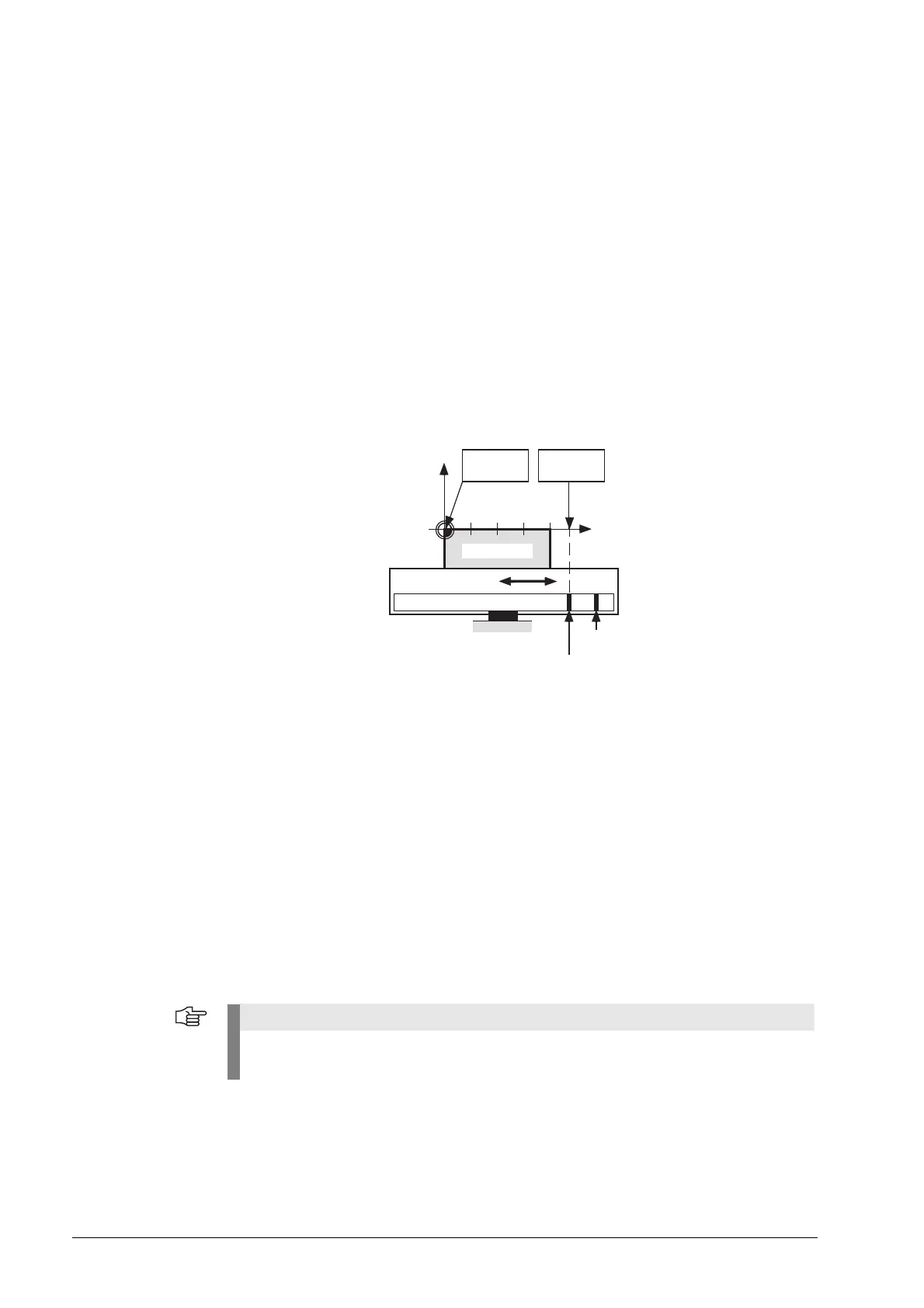

Reference marks HEIDENHAIN linear encoders (except EnDat) are designed with one or more reference marks.

The reference marks identify an axis position at a known distance from the machine datum. The

position of the datum selected by the machine operator is defined with respect to the machine

datum.

The datum and the actual position can be reproduced as soon as the reference marks are

traversed.

Machine

datum

The machine datum is the central reference mark of your machine tool.

It is defined by the machine tool builder.

The machine datum is required for ...

Defining the limits of traverse (software limit switches)

Moving to machine-referenced positions (such as tool change positions)

Setting the workpiece datum

Distance between

the scale reference

point and the

machinedatum

For position encoders with distance-coded reference marks, the machine datum is defined with

respect to the scale reference point, which is at the first reference mark after the beginning of

the measuring length.

If EnDat encoders are used, the machine datum refers to the datum of the EnDat encoder.

MP 960.x contains the distance between scale reference point and machine datum.

Spindle preset A corresponding angle encoder or also the motor encoder in the spindle motor may be used for

spindle orientation.

MP 3430.x contains the deviation of the reference mark from the desired position.

Measuring system

Machine table

REF Value

0

10 20 30 40

Machine datum

+Z

+X

0

Workpiece

datum

Workpiece

Reference mark

REF Value

–44.985

After removing and remounting a measuring system MP 960.x may have to be altered.

See “Resetting the machine datum” on page 18 – 288.