July 2010 22 – 369

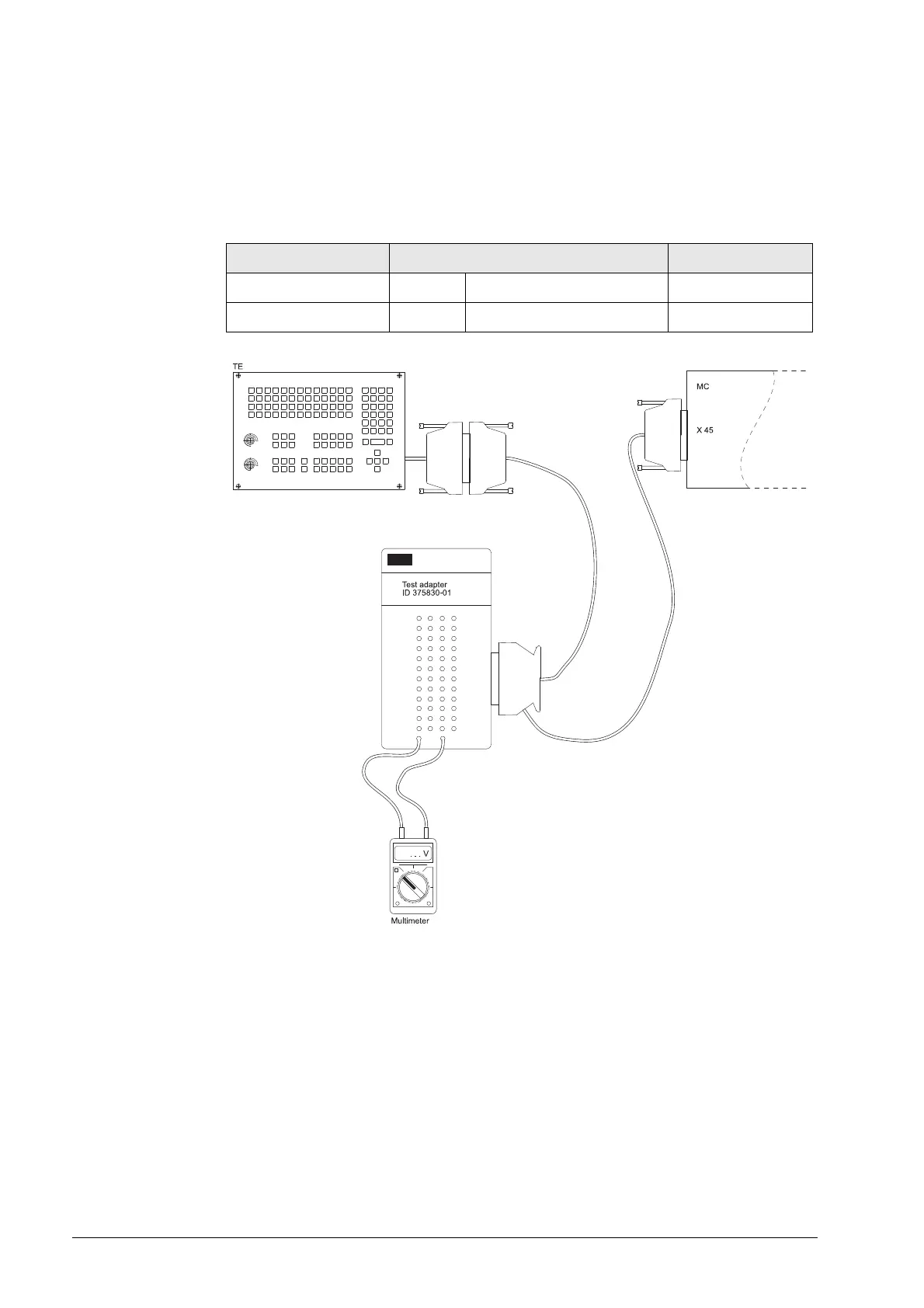

Measuring setup

with test adapter

Procedure:

8 Shut down the control and switch off the machine.

8 Insert the measuring adapter on the MC connector X45 between MC and TE cable.

8 Switch the machine back on again.

8 Using a multimeter, check the collector voltages of the potentiometers.

Figure: Potentiometer test with test adapter and multimeter

Potentiometers Pins Voltage range

Feedrate override F% 37 = 0V 35 = wiper potentiometer 0 ... approx. + 5V

Spindle override S% 37 = 0V 34 = wiper potentiometer 0 ... approx. + 5V