7-8

MAINTENANCE

Preparations for Inspection and Maintenance

d

WARNING: If ride control switch (3) is in the AUTO

position, the lift arm may unexpectedly rise. To

avoid an accident due to unexpected movement

of the lift arm, always turn ride control switch

(3) OFF before beginning the inspection and/or

maintenance of the machine.

d

CAUTION: If the machine moves unexpectedly,

a serious accident may result. Be sure to apply the

parking brake when parking the machine.

Unless specified otherwise, park the machine by following

the procedures below before beginning the inspection

and/or maintenance work.

1. Park the machine on a solid level surface.

2. Lower the working tools such as the bucket to the

ground.

3. Turn ride control switch (3) OFF.

4. Place forward / reverse lever (4) and forward / reverse

switch to neutral and place neutral lever lock (6) to

lock ( ) position.

5. Apply the parking brake (Turn parking brake (5) ON.)

6. Wedge the tires.

7. Run the engine at low idle speed for 5 minutes to

cool the engine. Turn key switch (7) OFF to stop

the engine. Again, turn key switch (7) ON and

place control lever lock switch (2) to the unlock (

) position. Fully operate the lift arm control lever

(1) 3 to 4 strokes to release residual pressure in the

hydraulic system. If inspection and/or maintenance

must be performed with the engine kept running,

use a signal person.

8. Be sure to place control lever lock switch (2) to the

lock ( ) position.

9. Turn key switch (7) OFF and remove the key.

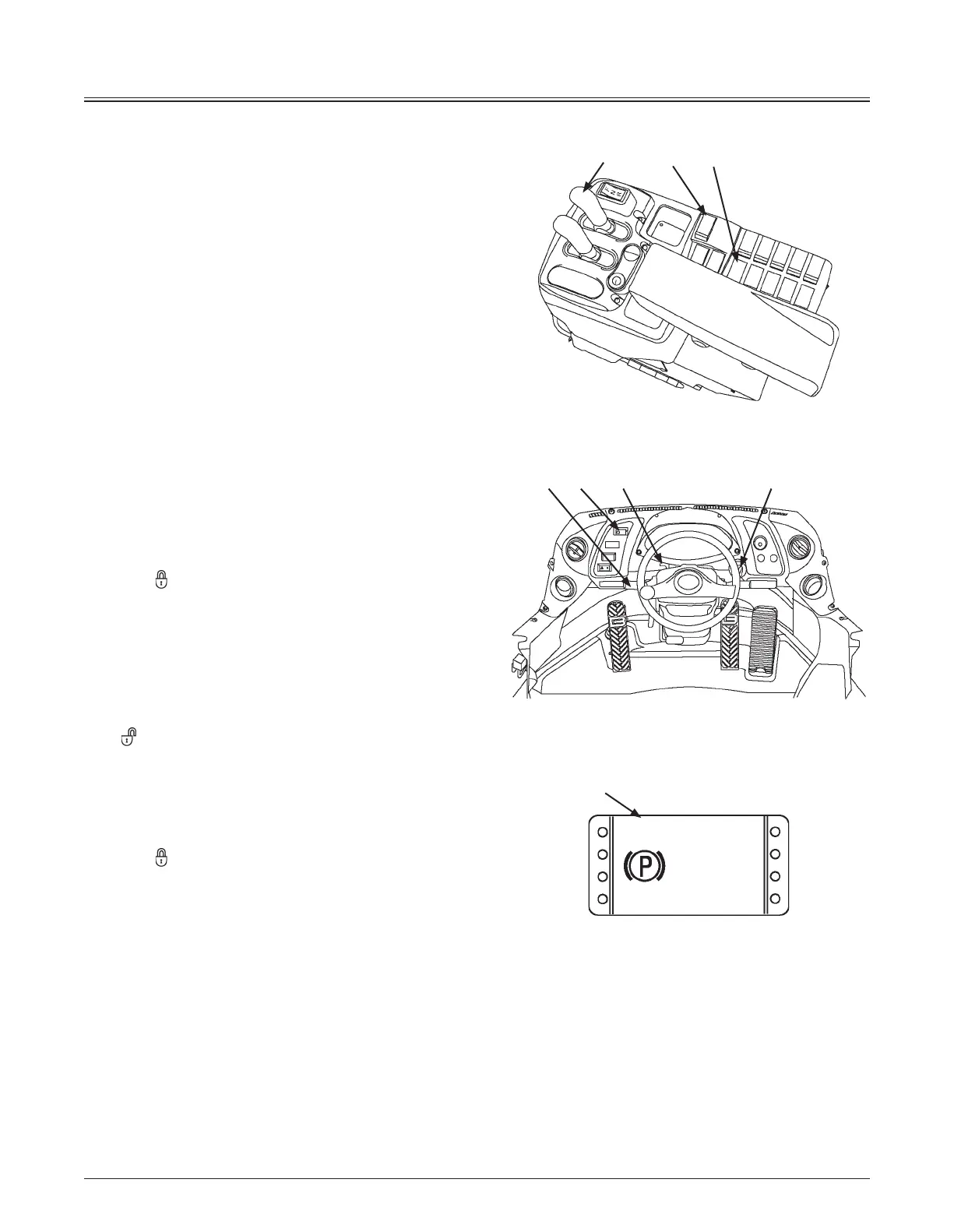

10. Start working only after putting an "UNDER

INSPECTION/MAINTENANCE" tag in a highly visible

place such as on the cab door or the control lever.

MNEC-01-036

MNEC-07-001

MNEC-01-058

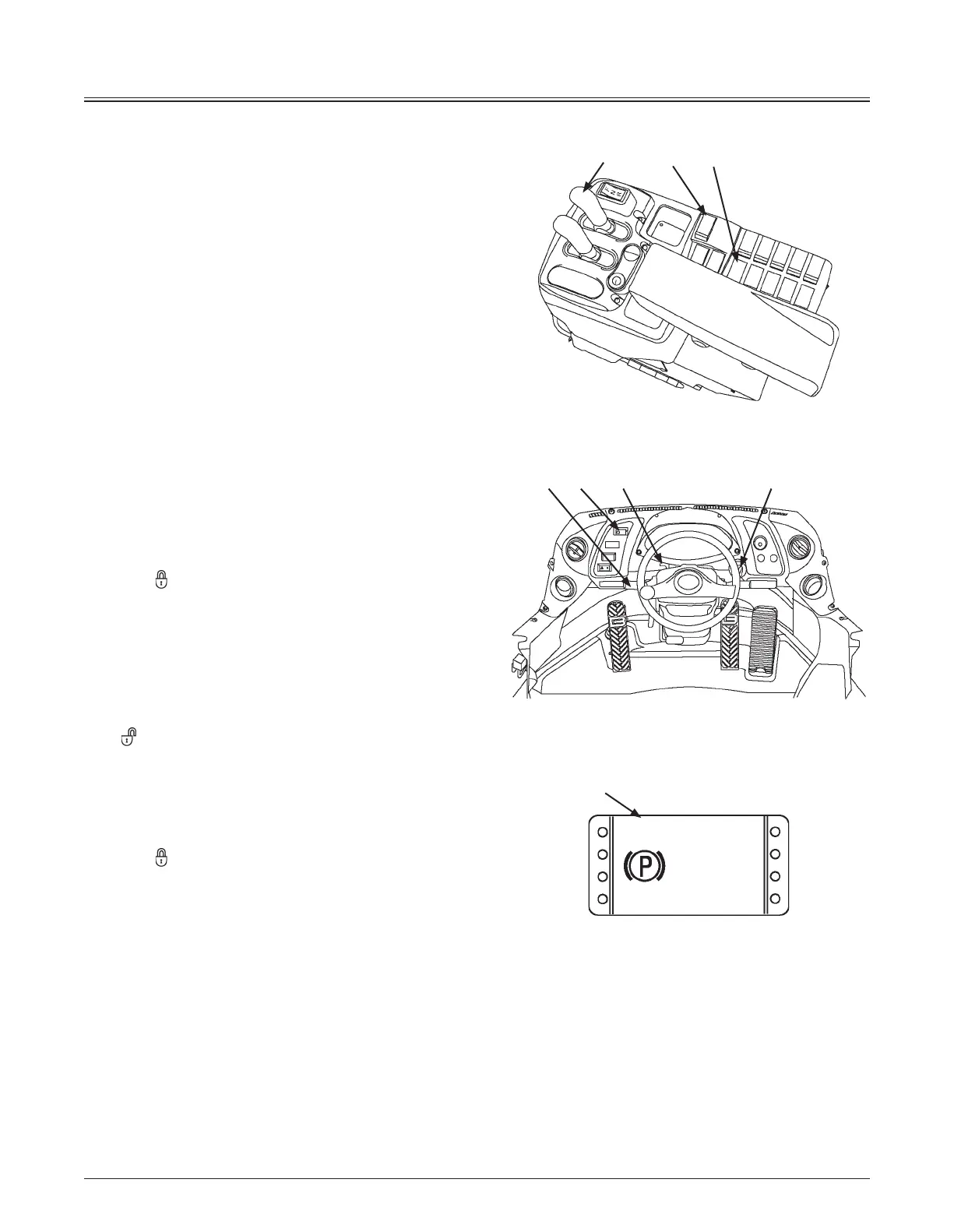

1 2 3

4 5 6 7

5

Loading...

Loading...