7-14

MAINTENANCE

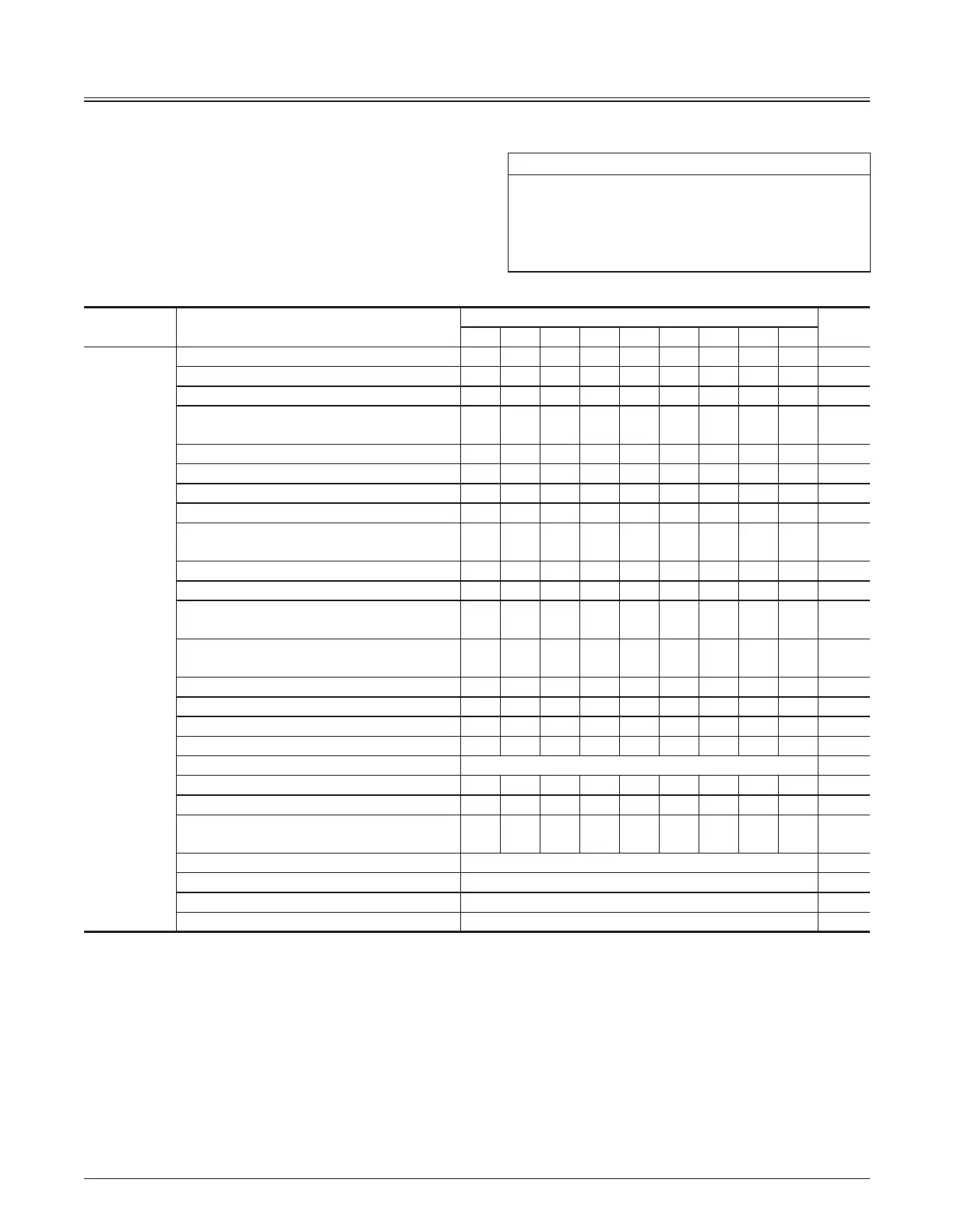

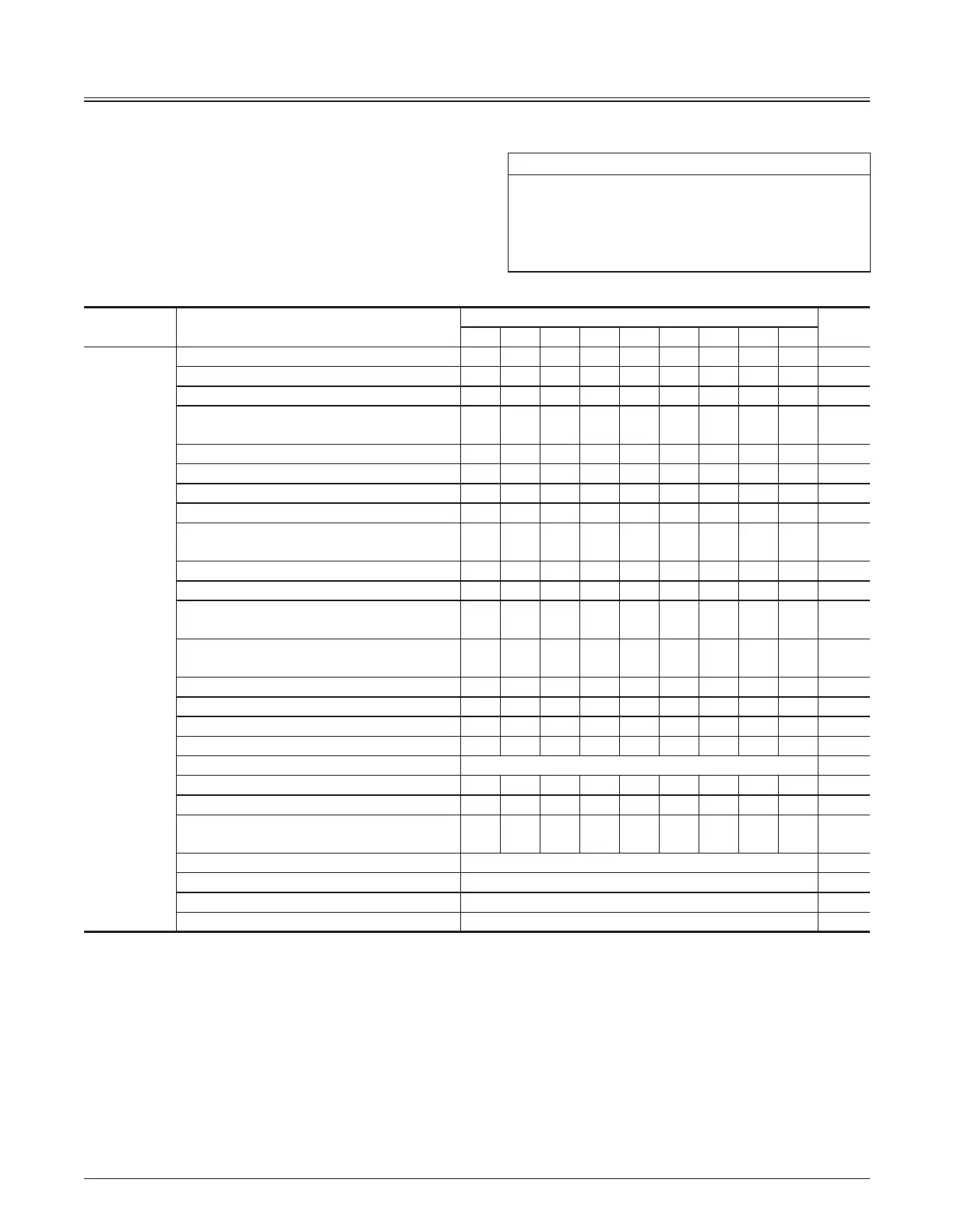

Inspection and Maintenance Table

Check and/or carry out the maintenance at intervals of

the specified operating hours below or the calender date,

whichever comes first.

IMPORTANT

Severe applications require more frequent

maintenance. Severe conditions include heavy dust,

extremely abrasive material, caustic chemicals,

extremely wet conditions or abnormally hot or cold

ambient temperatures.

: First time replacement or cleaning only

Section Item for check

Operating hours

Page

10 50 100 250 500 1000 2000 4000 4500

Engine

Check Engine Oil Level

7-32

Check Coolant Level

7-77

Check DEF/AdBlue® Level

7-128

Check Accelerator Pedal Operation, and

Exhaust Gas Color and Noise

7-110

Drain Fuel Filter

7-68

Check Fuel Level

7-65

Check Drive Belt

7-78

Check Fuel Hoses

7-73

Check Sound Absorbing Mat Around

Engine

7-112

Check Crankcase Breather Tube

7-36

Check Air Inlet System

7-75

Replace Engine Oil and Oil Filter Cartridge

7-33

7-35

Clean Radiator/Oil cooler Cores and Other

Cooling System

*3

7-81

Replace Fuel Main Filter Element

7-69

Replace Fuel Pre-Filter Element

7-70

Drain Water and Sediment from Fuel Tank

7-67

Clean Fuel Pump Strainer

7-71

Check Drive Belt Tentioner Every 1 years or 1000 hours 7-79

Replace Crankcase Air Breather Element

7-37

Check Vibration Damper

7-39

Replace DEF/AdBlue® Supply Module Main

Filter Element

7-131

Check and Adjust Valve Clearance Every 5000 hours 7-113

Replace Air Cleaner Element Indicator comes ON 7-74

Replace Coolant Every 2 years or 3000 hours 7-80

Check and Clean Aftertreatment Device As required, when regeneration indicator comes ON 7-125

f

NOTE:

*3 Shorten maintenance intervals when the machine is operated under severe conditions or when the machine is

continuously operated for a long period of time.

Loading...

Loading...