MAINTENANCE

7-79

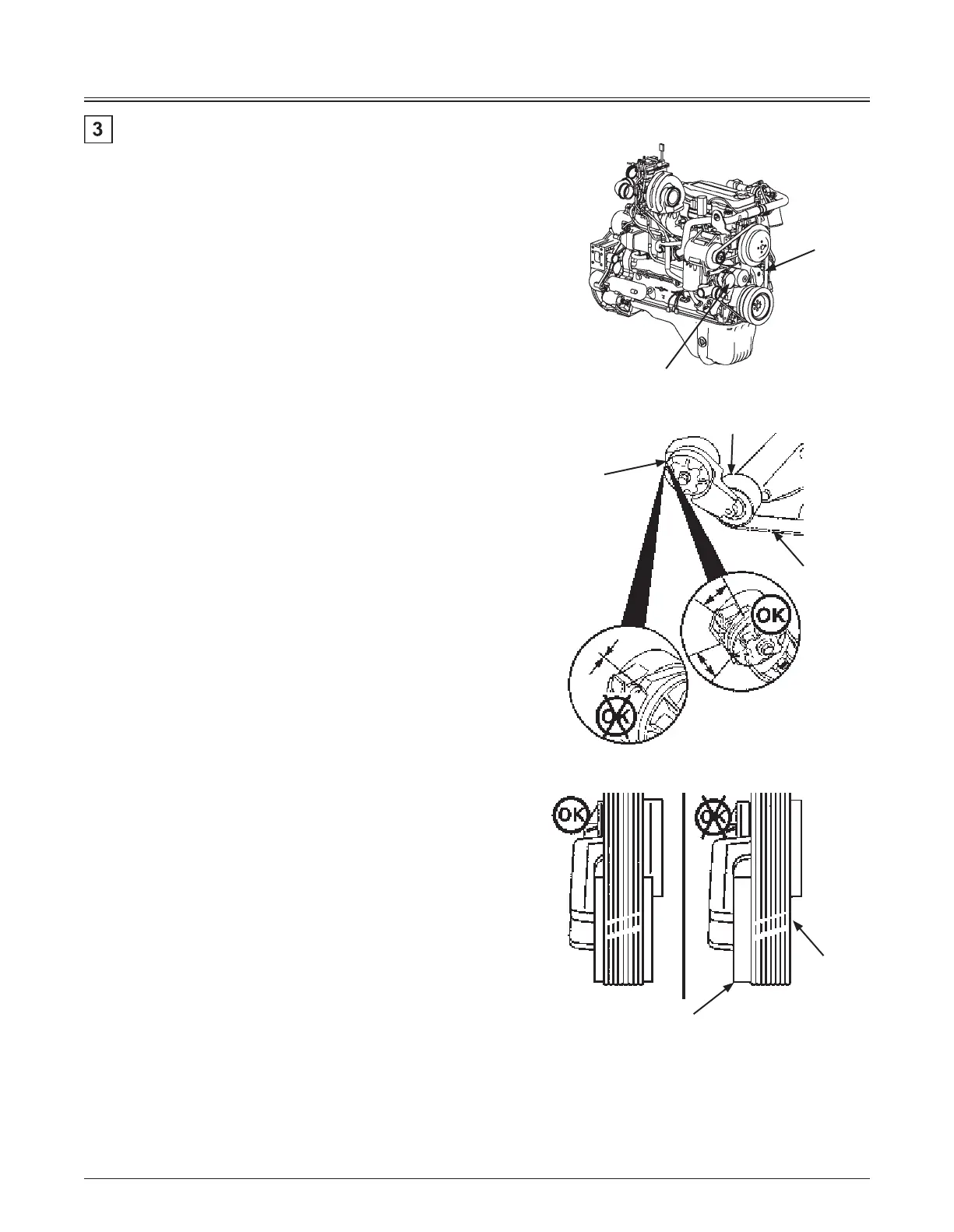

Check Drive Belt Tensioner

--- every 1000 hours or once a year

1. Park the machine following the same procedures as

described on page 7-8 for preparation of inspection/

maintenance work.

2. Install articulation lock bar to the front and rear of the

frame by following the procedures described on page

7-10.

3. Open the side cover to access the engine.

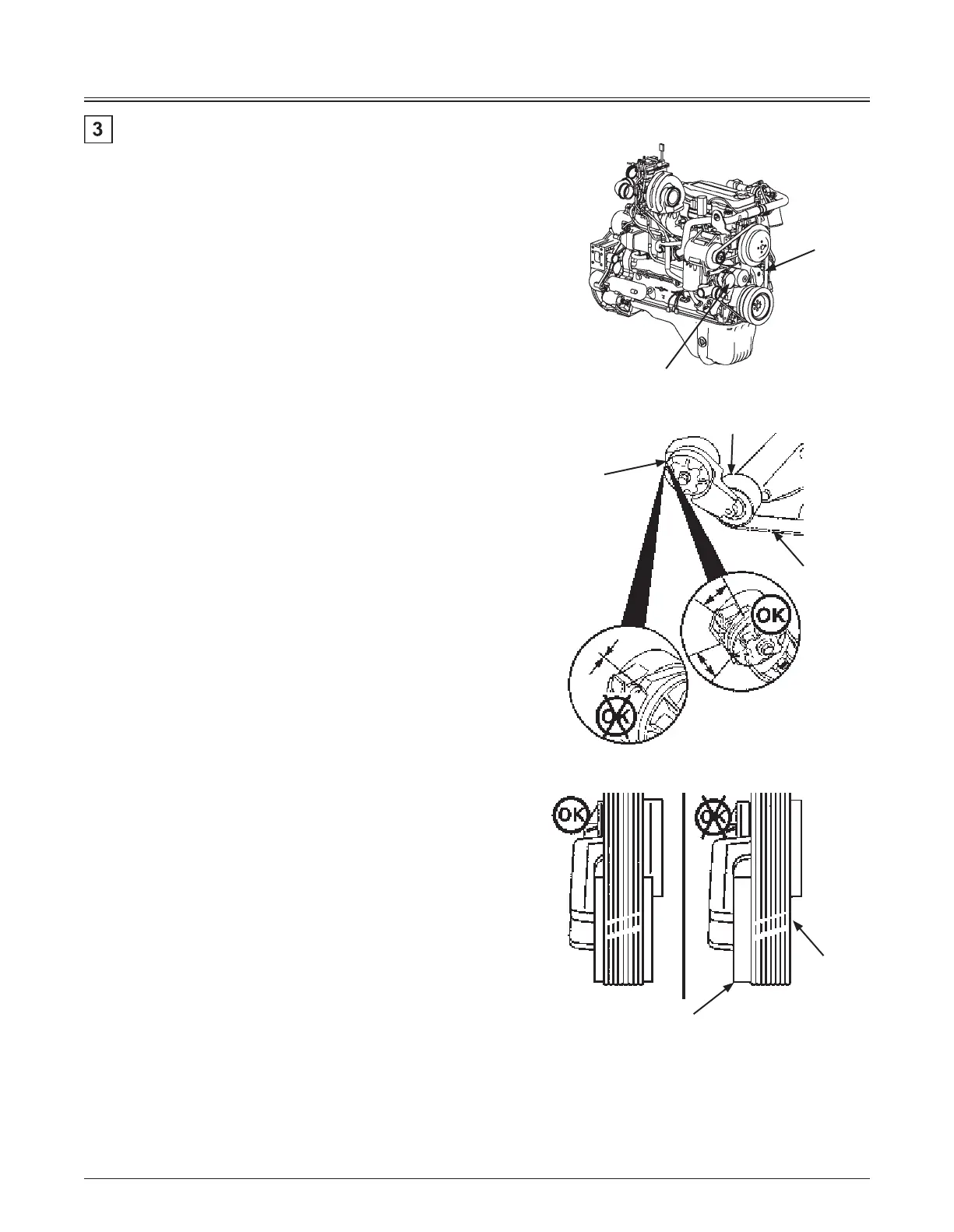

4. With the belt installed, verify that neither tensioner arm

stop is in contact with the spring casing stop. If either

stop is touching, drive belt (1) must be replaced.

After replacing the belt, if the tensioner arm stops

are still in contact with the spring case stop, the belt

tensioner must be replaced.

5. Check tensioner (2) for cracks on arm, pulley, and stops. If

any cracks are observed, the drive belt tensioner must be

replaced.

f

NOTE: Consult your nearest authorized dealer for the drive

belt tensioner replacement.

6. Check belt tensioner pulley (3) for any dirt or damage.

If ir is dirty or damaged, contact your nearest authorized

dealer for cleaning or replacement.

7. Check the location of drive belt on belt tensioner pulley

(3).

The belt must be centered on, or close to the middle of,

the pulley.

Misaligned belts, either too far forward or backward, can

cause belt wear, belt roll-off failures, or increase uneven

tensioner bushing wear.

90Z7B-7-77-2

90Z7B-7-77-3

2

1

3

3

1

MNEC-07-116

1

2

Loading...

Loading...