Wheel System, Non-traction 181Service Manual – SC6500

™

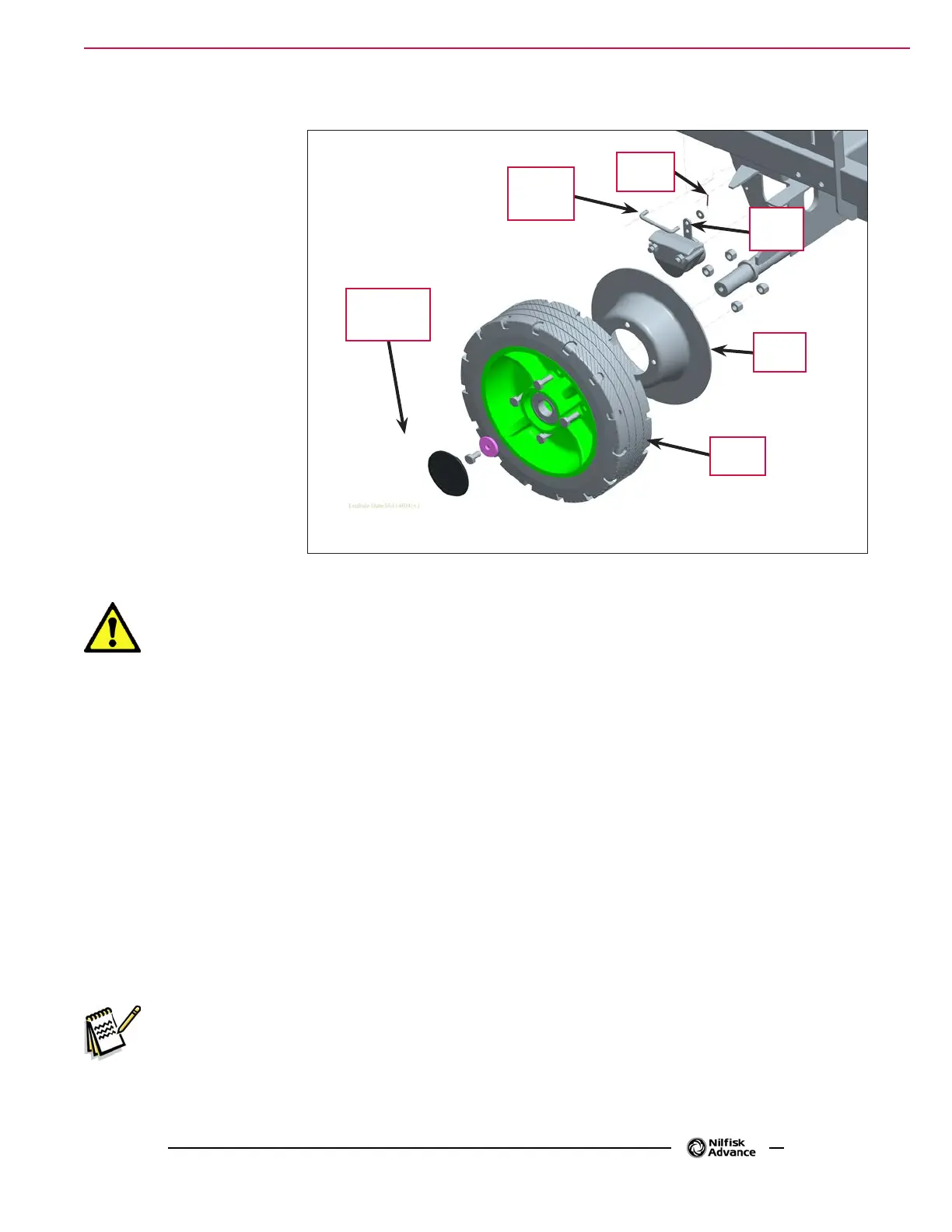

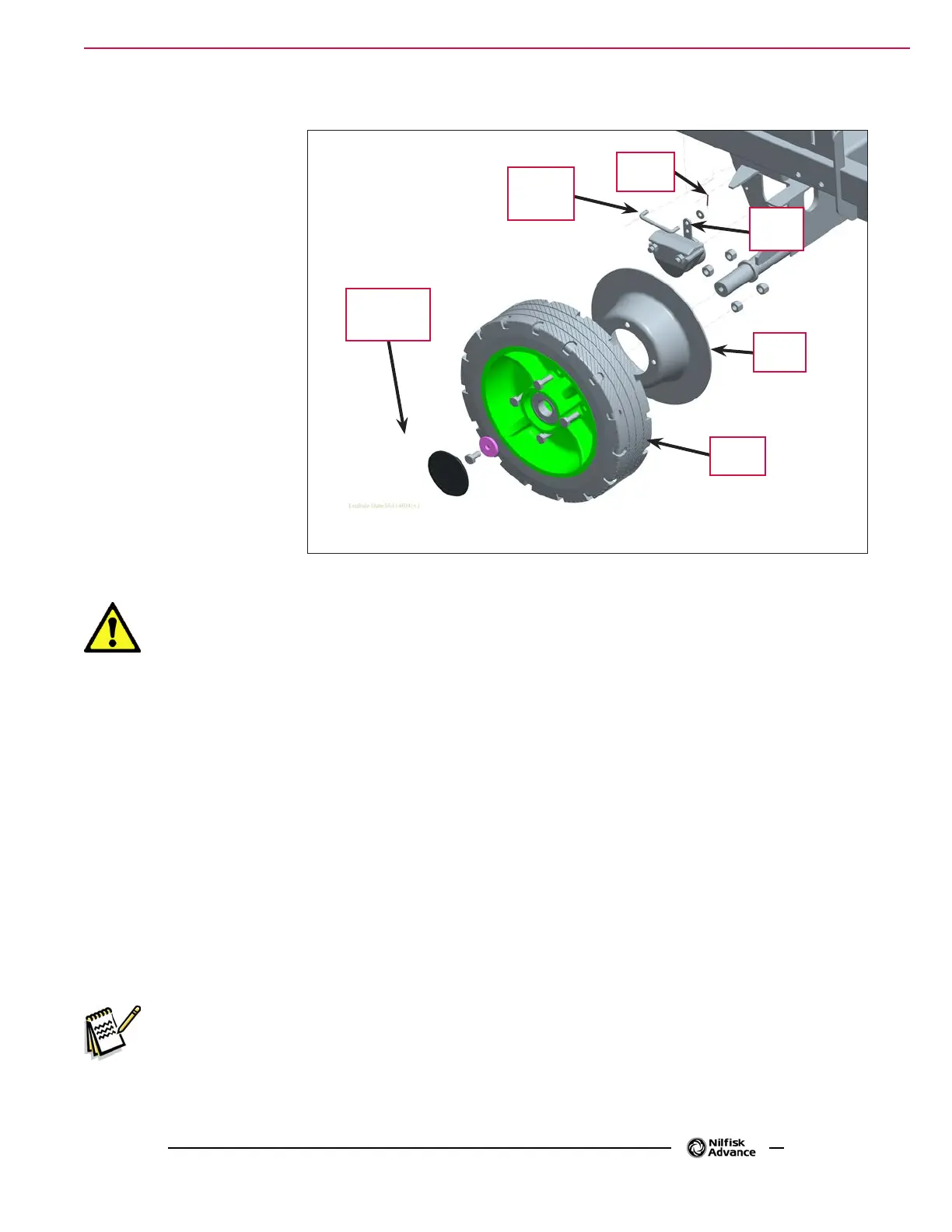

Rear Wheel and Brake Caliper

1. Remove the Cotter Pin

and washer from the

Brake Linkage Rod and

disconnect the Brake

Linkage Rod

from the

top brake arm

mounting hole.

2. Remove the Cotter Pin

and washer from the

Brake Linkage Rod and

disconnect the Brake

Linkage Rod

from the

brake arm mounting hole.

3. Loosen the M10-1.5

x 20mm Hex Screw

holding the Rear Wheel

to the axle.

4. Position a suitable jack

underneath the wheel

axle and jack up the

machine so the wheel is

approximately 1 inch off

the oor.

Warning! Place wood blocking under the rear axle as the machine is only being supported by

the jack. This is to prevent any accidents or machine damage when the wheel is off of

the machine.

5. Remove the M10-1.5 x 20mm Hex Screw and washer and carefully pull the complete wheel and brake

assembly off the axle.

6. If you are replacing the wheel:

a. Remove the four M10-1.5 x 30mm Hex Screws and nuts holding the Brake Rotor to the Rear Wheel hub.

b. Reattach the salvaged Brake Rotor to the new Rear Wheel hub.

7. To reinstall the wheel and brake assembly:

a. Place the brake caliper onto the rotor. Adjust the gap between the pads and the rotor to 0.035”

(0.89mm) using a feeler gauge. See Brake Caliper Pad Wear Adjustment.

b. While holding the caliper on the rotor, and aligning the caliper slots with the chassis, slide the wheel

and brake assembly onto the axle.

c. Install the M10-1.5 x 20mm Hex Screw and washer to fasten the Rear Wheel to the axle.

Service Note: Apply a small amount of Loctite 242 (blue) thread sealant to the M10-1.5 x 20mm Hex

Screw

to prevent the screw from loosening.

d. Remove the wood blocking from the rear axle, then lower the jack.

e. Reconnect the Brake Linkage Rod to the brake arm top hole and reinstall the washer and Cotter Pin.

M10-1.5 x

20mm Hex

Screw

Brake

Arm

Rear

Wheel

Brake

Rotor

Cotter

Pin

Brake

Linkage

Rod

Loading...

Loading...