Section 10 Transferring Data 10-3 Data Transfer Using SPMA

NS-Designer Operation Manual

Transferring/Monitoring Ladder Programs via a PT

Data, such as a ladder program, can be uploaded/downloaded from the CX-Programmer to a PLC

connected by a Serial or Controller Link network through a PT connected with the PLC by an Ethernet

network.

Controller Link

1:N NT Link

Etherne

NS-Designer

PT

PLC

PLC

Reference

♦

The CX-Net cannot be used when using the CX-Programmer through the PT.

♦

♦

Updating screen display and responses of touch input actions may slow down when using the

CX-Programmer through the PT.

Correct operation is possible only for the configurations described in this manual.

R

R

e

e

f

f

e

e

r

r

e

e

n

n

c

c

e

e

10-3-3 System Configuration

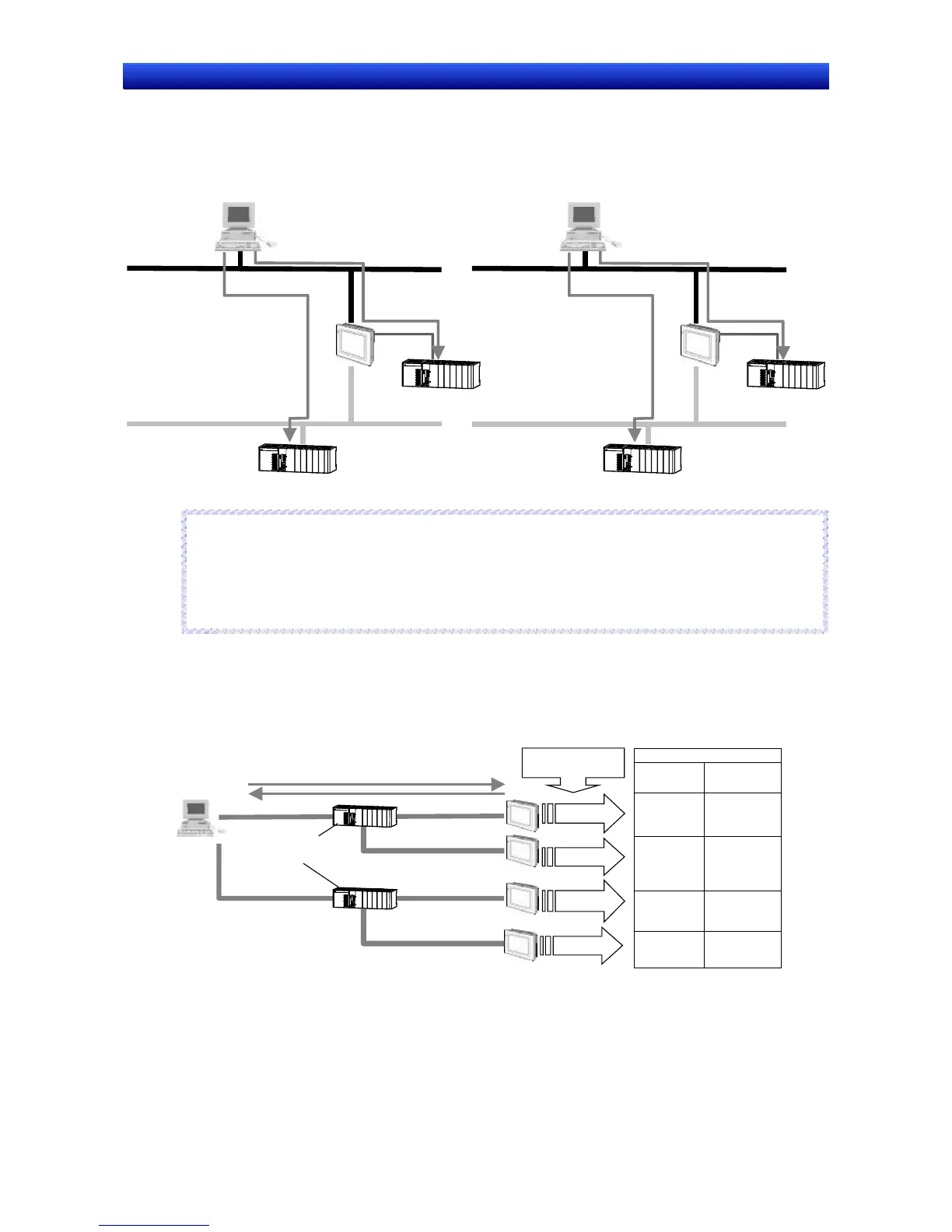

Transferring Screen Data from the NS-Designer to a PT through a PLC

Screen data can be transferred from the NS-Designer to the PT as shown below. Procedures are dif-

ferent depending on the configuration.

NS-Designer

Serial (Tool Bus/modem)

Ethernet/Controller Link

Ethernet/Controller Link

Screen Data

See P10-36.

Details

See P10-39.

CPU Unit

Serial, 1:N NT Links

CS/CJ-series

PLCs (Relay)

Comms.Setting

Computer-PLC PLC-PT

Serial COM

Modem

Serial

Serial COM

Modem

Ethernet or

Controller Link

Ethernet

Controller Link

Serial

Ethernet

Controller Link

Controller Link

* Cables must be connected to the built-in RS-232C port or peripheral port on the PLC’s CPU Unit

by a serial 1:N NT Link. To make settings for the expansion routing tables (routing tables that treat

serial communications as Network communications), CX-Programmer Ver. 3.1 or later is required

.

CPU Unit

Serial, 1:N NT Links

See P10-44.

See P10-49.

Ethernet/Controller Link

To transfer screen data to a PT through a PLC, one of the following CPU Units (Lot No. 030201 and

later) is required. CPU Units and lot numbers not listed in the following table do not support this func-

tion.

10-34

Loading...

Loading...