6-62

6

Operation Selection After Cooling Fan Fault

Use the parameter setting to select the operation of the motor after a cooling fan fault occurs. This function can

be used for times when a motor should not be stopped quickly (with an emergency stop.)

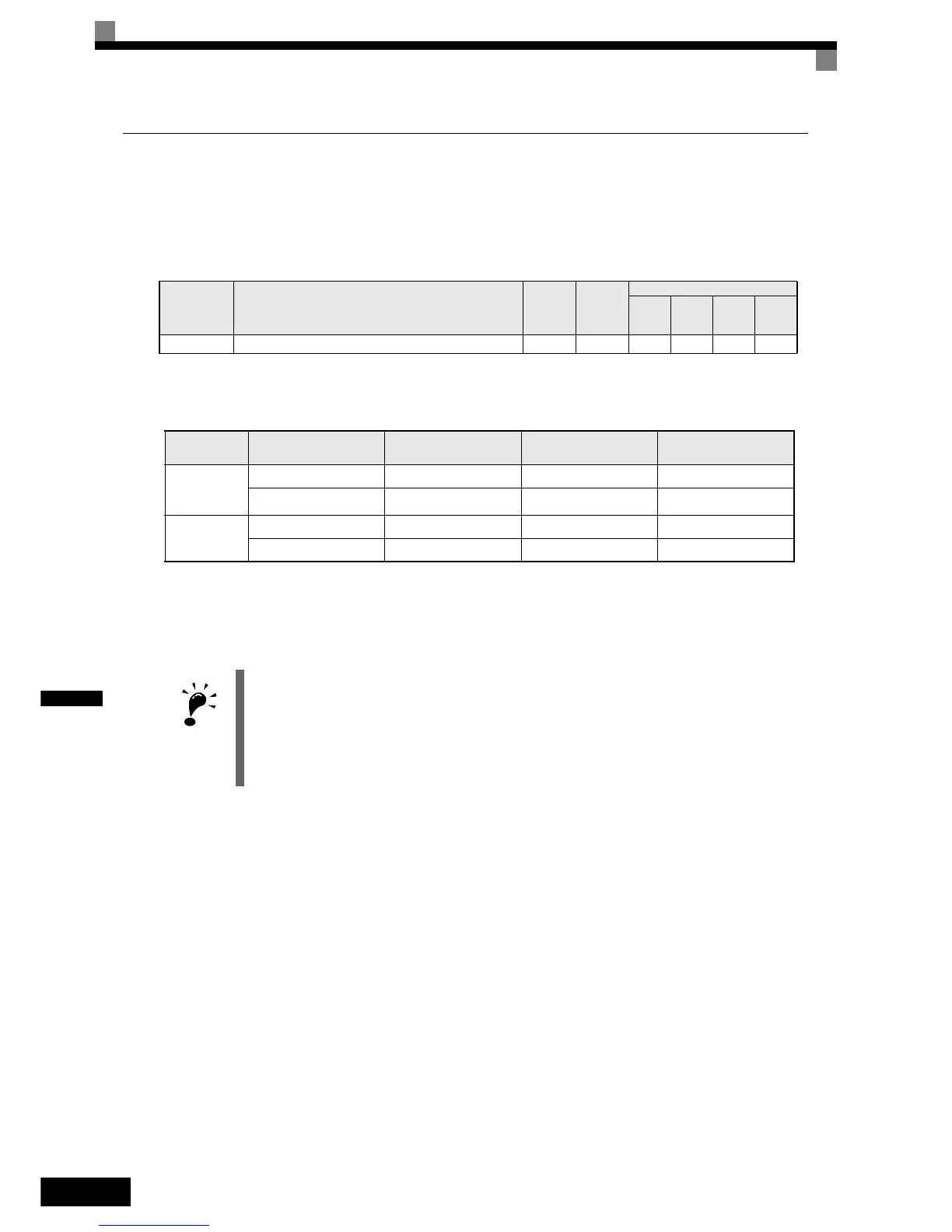

Related Parameters

The following table describes the operation of the motor and the display of the Digital Operator in accordance

with the settings of the L8-32 if a cooling fan fault occurred.

Parameter

No.

Name

Factory

Setting

Change

during

Opera-

tion

Control Methods

V/f

V/f with

PG

Open

Loop

Vector

Closed

Loop

Vector

L8-32 OH1 detection of Inverter’s cooling fan 1 No A A A A

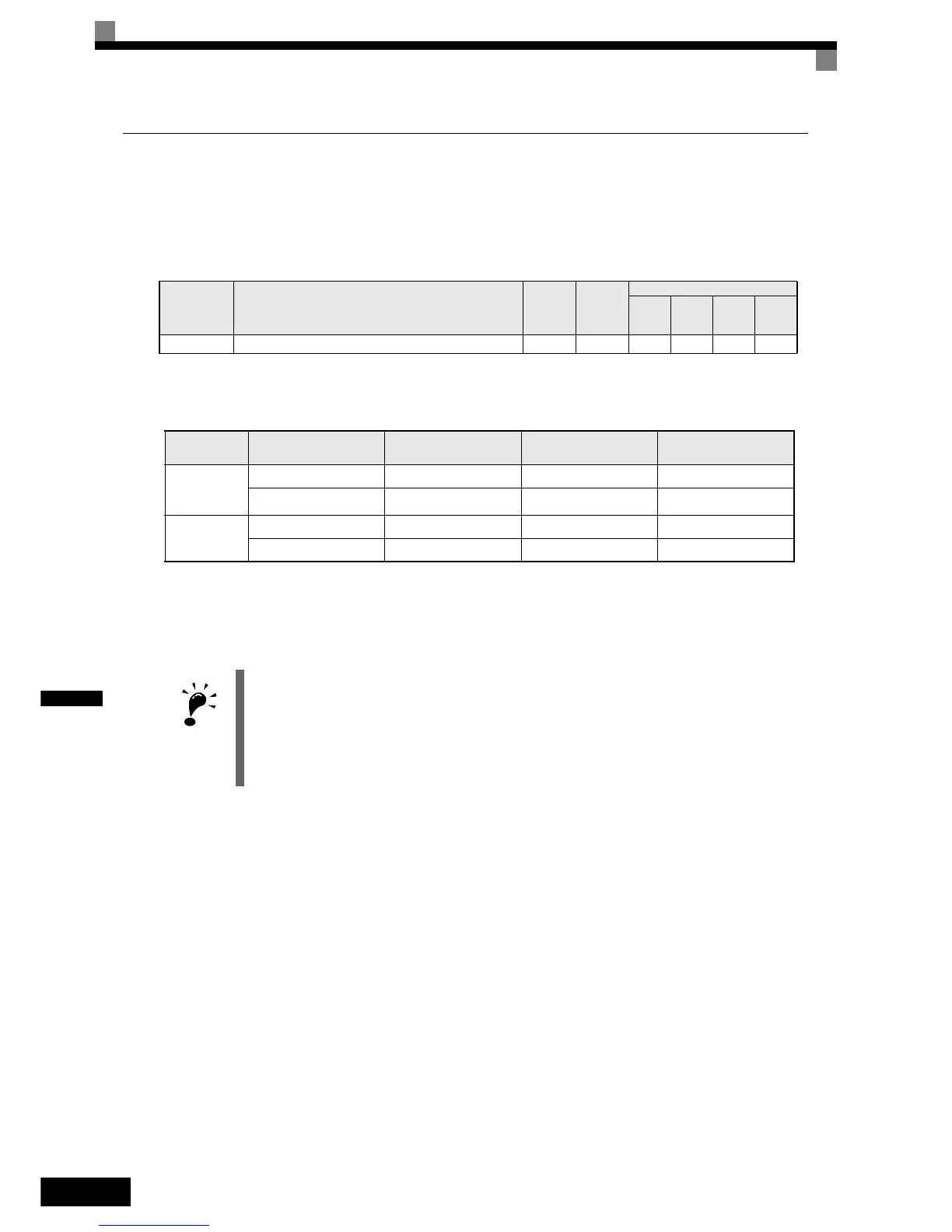

Setting

value

Fault Digital Operator Motor Operation

Multi-function Digital

Output

0

Cooling Fin Overheat OH1 Coast to stop Fault

Inverter’s Cooling Fin FAN (flashing)

Continue operation

* 1

* 1. If l8-32 is set to 0, the motor will continue running even if a cooling fan fault occurred. However, the Inverter rated output current and the

overload capacity will be reduced. The rated output current will be reduced to 80% of the Inverter rated current and the overload capacity

will be reduced to following values:

When CT (C6-01=0, default) is selected: 100% for 3 minutes, 150% for 15 seconds.

When VT (C6-01=1 or 2) is selected: 100% for 30 seconds, 120% for 10 seconds.

Alarm

1

Cooling Fin Overheat OH Coast to stop Fault

Inverter’s Cooling Fin OH1 Coast to stop Fault

IMPORTANT

If L8-32 is set to 0, be sure to set H2-01 to H2-03 multi-function digital outputs to 10 (Alarm)

or to 3D (Inverter’s cooling fan fault.) If a cooling fan fault occurs, stop the Inverter immedi-

ately and replace the cooling fan. If the Inverter continues to run while a cooling fan fault

occurs, the Inverter’s cooling ability will be affected and the Inverter’s internal temperature

will increase and shorten the Inverter’s life time. During a cooling fan fault, the cooling fan

stops for about 3 seconds every minute (interval operation.)

Loading...

Loading...