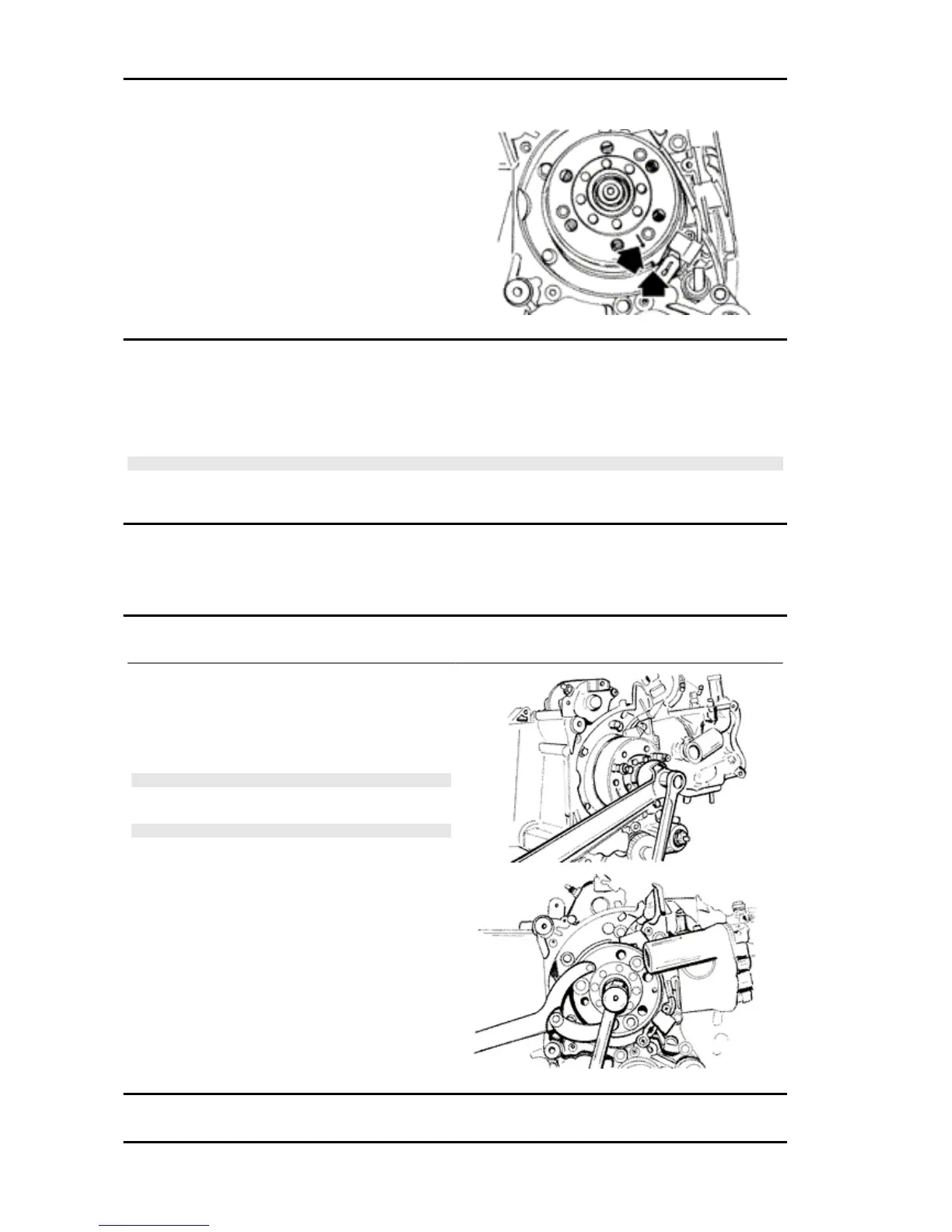

- Place the flywheel with the top dead centre mark aligned with the crankcase.

- Place the flywheel cover by aligning the reference marks of the drive and the crankcase cover.

- Reassemble the cover on the engine, placing the three connectors in the drive for the water pump.

- Carry out the steps in the reverse order from the dismantling procedure.

CAUTION

TAKE CARE TO CORRECTLY POSITION THE FLYWHEEL CONNECTOR. MAKE SURE THE CEN-

TRING DOWELS ARE PRESENT.

Flywheel and starting

- Check the integrity of the internal plastic parts of the flywheel and the Pick-Up control plate.

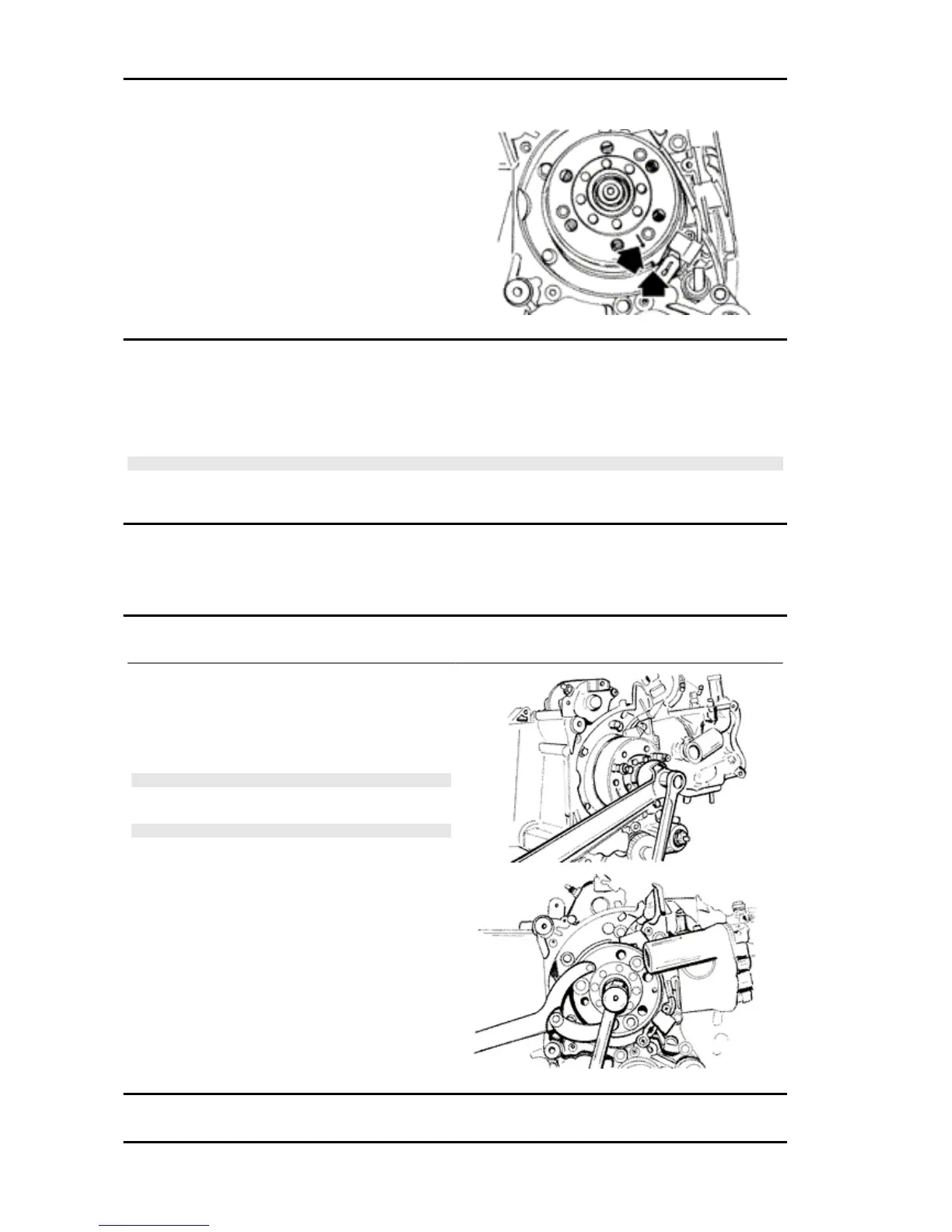

Removing the flywheel magneto

- Lock the rotation of the Flywheel with the calliper

spanner tool.

- Remove the nut.

- Take out the flywheel.

CAUTION

THE USE OF A CALLIPER SPANNER OTHER THAN THE

ONE SUPPLIED COULD DAMAGE THE STATOR COILS

N.B.

THE FLYWHEEL OF THE 200 CM³ MODELS FEATURES

ENHANCED INERTIAL MASS.

Engine Carnaby 125 - 200

ENG - 128

Loading...

Loading...