For the 200 models reposition the shim washers

as in the original fitting.

- Fit the 11 screws and tighten them to the pre-

scribed torque.

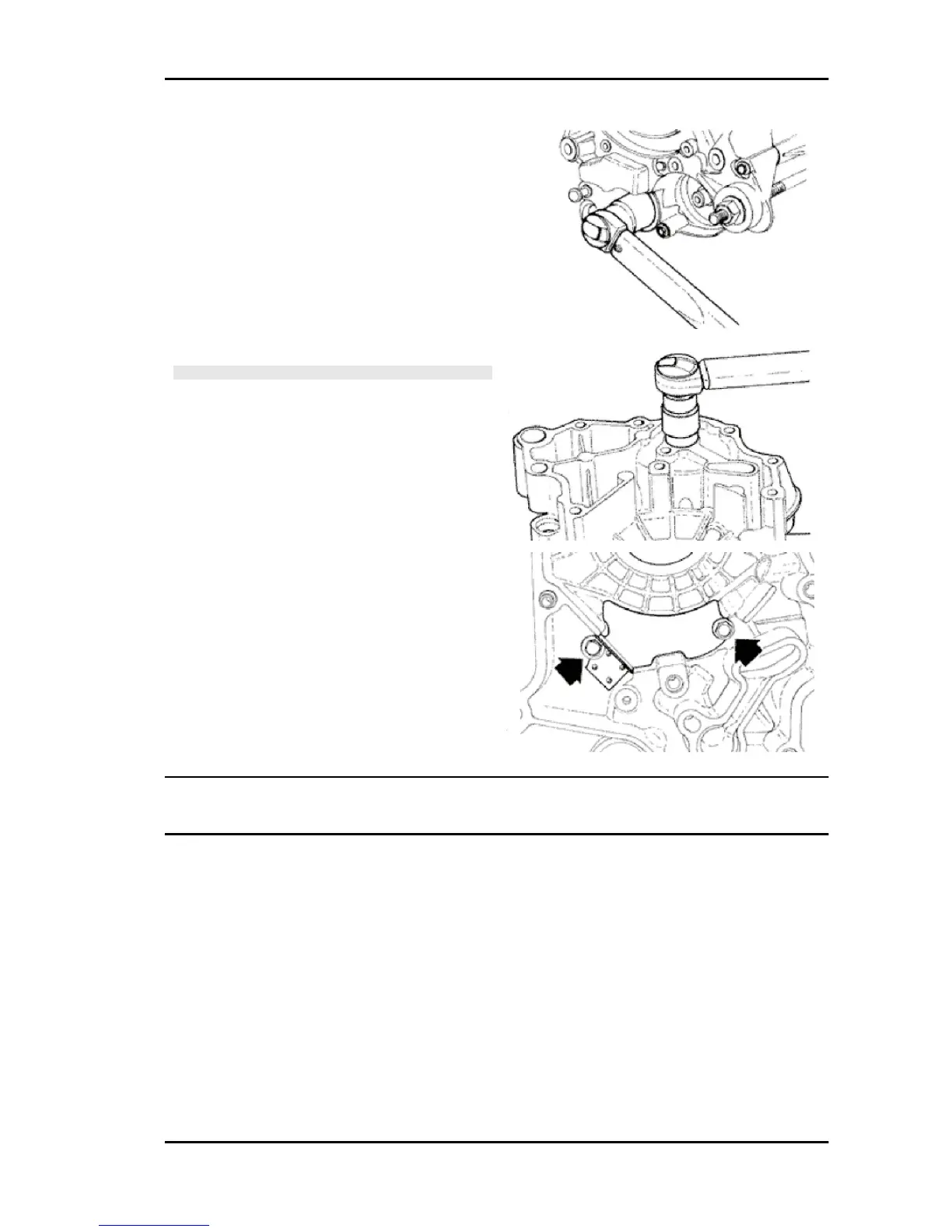

- Lubricate the flywheel oil seal.

- Using the appropriate tool, assemble the oil seal.

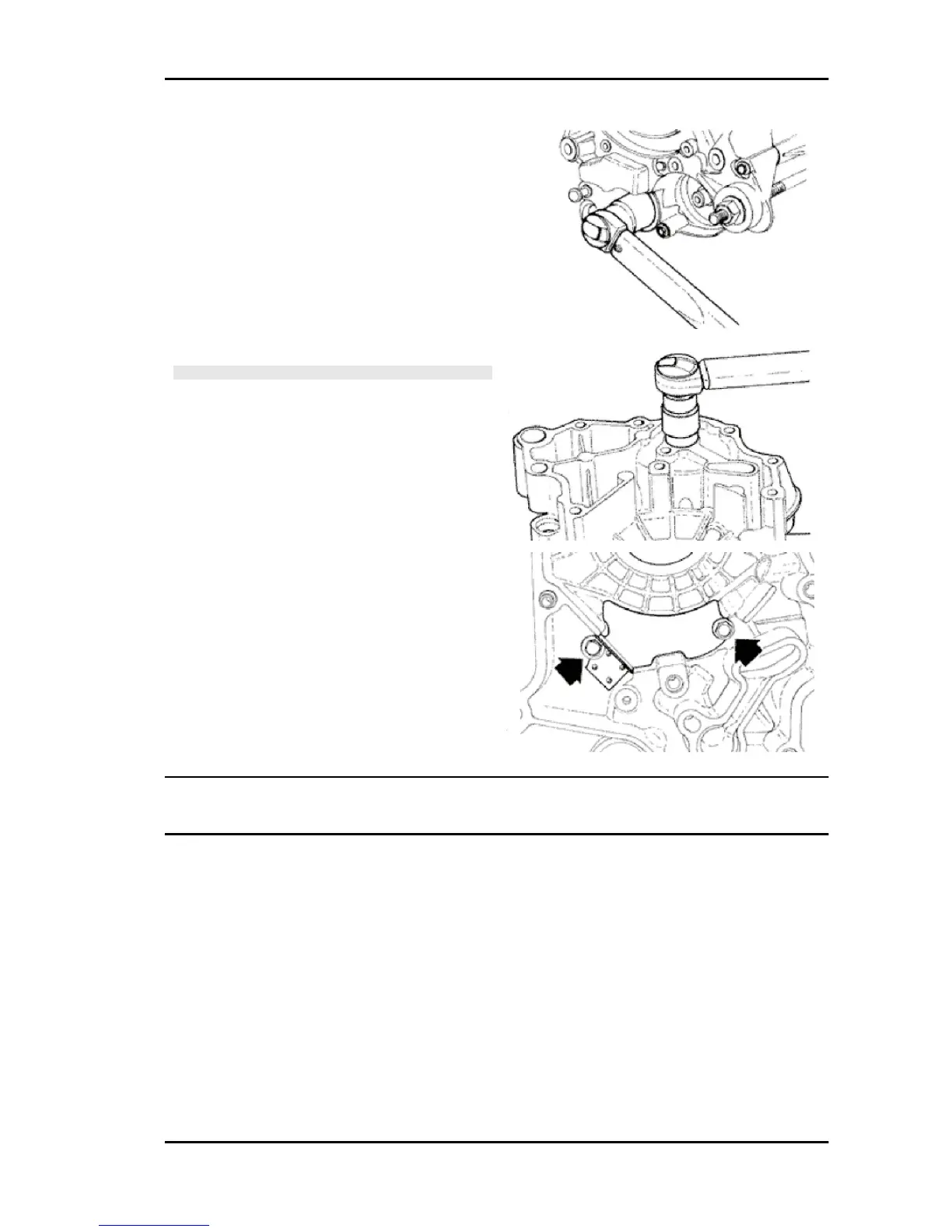

- Fit a new O-ring on the pre-filter and lubricate it.

- Insert the filter on the engine with the relative cap.

Tighten to the specified torque.

N.B.

FAILURE TO USE THE SPECIFIC TOOL CAN RESULT IN

AN INCORRECT DEPTH POSITION AND AS A CONSE-

QUENCE IN INADEQUATE OIL SEALING.

Specific tooling

020425Y Punch for flywheel-side oil seal

Locking torques (N*m)

Internal engine crankcase bulkhead (transmis-

sion-side half shaft) screws 4 ÷ 6 Oil filter on

crankcase fitting 27 ÷ 33 Engine-crankcase cou-

pling screws 11 ÷ 13 Engine oil drainage plug/

mesh filter 24 ÷ 30

Lubrication

Conceptual diagrams

LUBRICATION CIRCUIT

Carnaby 125 - 200 Engine

ENG - 161

Loading...

Loading...