Loading...

Loading...

Do you have a question about the PIAGGIO Carnaby 125 and is the answer not in the manual?

| Displacement | 124 cc |

|---|---|

| Front Suspension | Telescopic fork |

| Engine Type | Single cylinder, 4-stroke |

| Cooling System | Air-cooled |

| Transmission | CVT |

| Front Brake | Disc brake |

General safety guidelines applicable to all maintenance operations performed on the vehicle.

Guidelines for using genuine parts, specific tools, and proper refitting procedures.

Locating and identifying chassis and engine prefixes for models 125 and 200.

Weights and overall dimensions for both the 125 and 200 models.

Technical details for the 125cc and 200cc engines, including type, capacity, and power.

Information on transmission, fluid capacities, and electrical system components for 125cc models.

Details on electrical systems, chassis, suspensions, brakes, wheels, and tyres.

Specifications and identification for the Keihin carburettor used in 125cc and 200cc versions.

Specified torque values for steering components and frame assembly fasteners.

Torque specifications for suspension, brake, muffler, and lubrication system components.

Torque values for cylinder head, transmission, flywheel, and cooling system parts.

Categories and clearances for cylinder-piston assembly with different cylinder materials.

Dimensions and quantities for engine sealing rings for various piston oversizes.

Specifications for crankshaft bearings, couplings, and crankcase dimensions.

Axial clearance for crankshaft and piston protrusion measurement for gasket selection.

Table listing recommended products for engine oil, brake fluid, and other maintenance fluids.

A catalog of essential tools required for vehicle maintenance and repair procedures.

Schedule of recommended maintenance tasks based on time intervals or mileage.

Procedures for carburettor service and checking spark advance and ignition timing.

Procedures for spark plug, hub oil, air filter, and engine oil/filter service.

Checking oil pressure, ignition timing, valve clearance, coolant level, and brake fluid levels.

Diagnosing and resolving poor engine performance, starting difficulties, and overheating.

Troubleshooting clutch, braking system, and suspension problems.

Diagnosing and resolving battery, turn signal, and steering/suspension issues.

Identifying and addressing suspension oil leakage problems.

Wiring diagrams, component keys, and legends for the vehicle's electrical system.

Visual guide to the location of key electrical components on the scooter.

Procedures for checking ignition circuit, Pick-Up, HV coil, stator, and voltage regulator.

Instructions for battery charging, servicing, and electric fuel pump checks.

Steps for removing the exhaust system and the engine from the vehicle frame.

Procedures for removing, inspecting, and refitting the automatic transmission cover and components.

Steps for removing, inspecting, and refitting the clutch assembly and driven pulley components.

Procedures for removing, inspecting, and refitting the cylinder, piston, head, and valves.

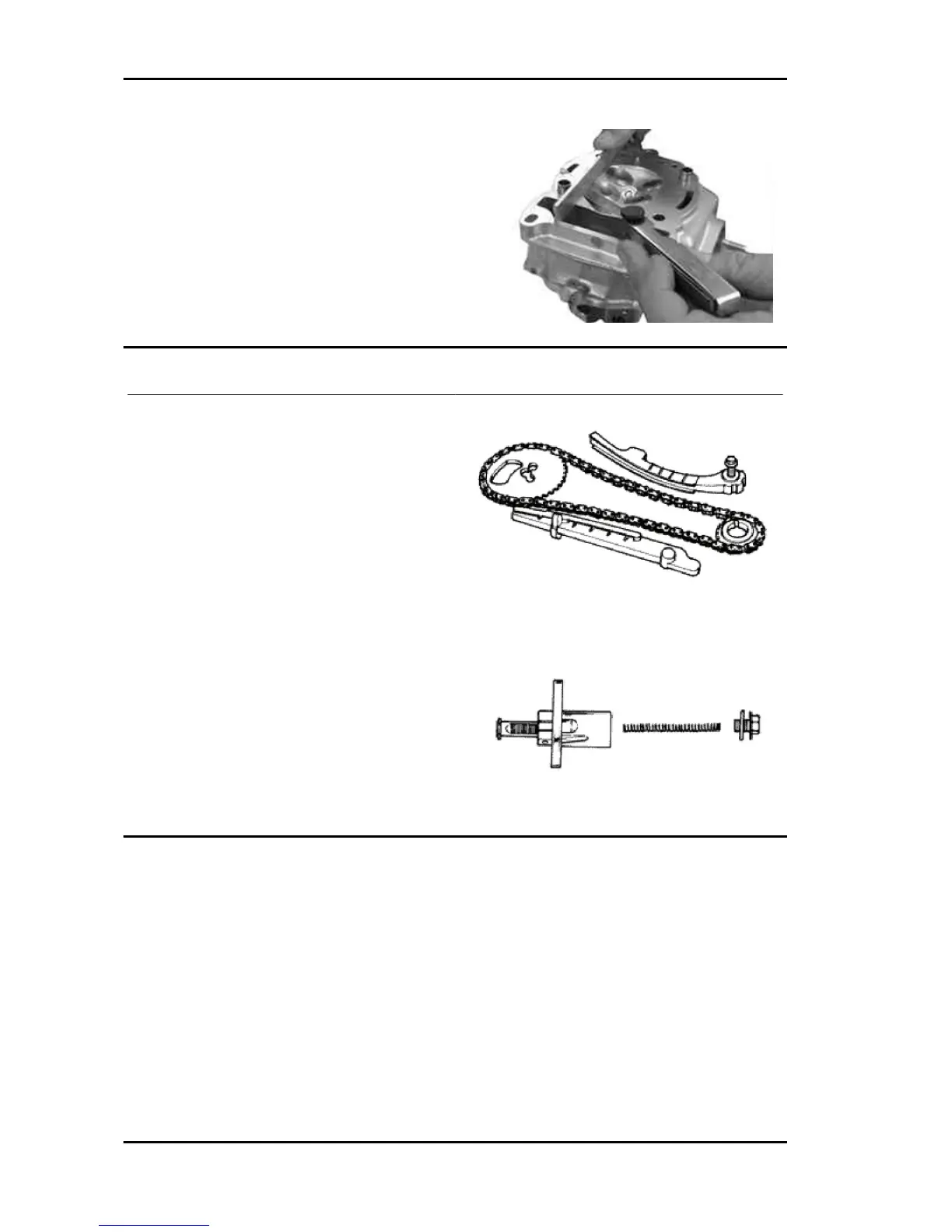

Inspecting and refitting camshaft, timing system, and carburettor components.

Procedure for warming up the engine and adjusting idle speed and carburetion.

Procedures for removing, overhauling, and refitting the front wheel and its hub bearings.

Steps for removing and overhauling the handlebar and front fork assemblies.

Procedures for refitting and servicing steering column bearings and headstock components.

Steps for removing and refitting the rear wheel, brake disc, and swing-arm.

Procedures for removing and refitting shock absorbers and the exhaust bracket.

Procedures for refitting and lubricating centre-stand components.

General rules and warnings regarding brake fluid handling and system maintenance.

Procedures for removing, overhauling, and refitting the rear brake calliper and disc.

Steps for removing, overhauling, and refitting the front brake calliper and disc.

Procedures for replacing front and rear brake pads, including thickness checks.

Procedures for bleeding air from the rear and front brake systems.

Steps for removing, overhauling, and refitting the front and rear brake master cylinders.

Diagram of the cooling system and procedure for checking the electric fan.

Testing the thermoswitch and procedures for replacing engine coolant.

Steps for removing, checking, and refitting the engine thermostat.

Procedures for removing the seat, rear rack, and handlebar covers.

Steps for removing the instrument panel and front handlebar fairing.

Procedures for removing headlight, legshield panels, and knee guards.

Steps for removing ignition key switch and front wheel housing components.

Procedures for removing taillight, footrests, and side fairings.

Steps for removing rear mudguard and underseat helmet compartment.

Procedures for removing fuel tank and front mudguard components.

Steps for removing radiator fan, expansion tank, and related hoses.

Visual checks for appearance and proper tightening of critical fasteners.

Verification of electrical system functionality and battery condition.

Checking fluid levels and performing a road test to assess vehicle performance.

Post-road test checks on starting, steering, and overall system functionality.

Recommended time intervals for engine part service and replacement.

Recommended time intervals for crankcase and crankshaft component service.

Recommended time intervals for cylinder-piston and related components.

Recommended time intervals for cylinder head, valves, and gasket service.

Recommended time intervals for camshaft and timing system component service.

Recommended time intervals for driven pulley, clutch, and related parts service.

Recommended time intervals for oil pump and sump unit service and replacement.

Recommended time intervals for final gear and driving pulley component service.

Recommended intervals for carburettor and exhaust system maintenance.

Recommended intervals for air cleaner and chassis component replacement.

Recommended intervals for electrical device and fuse replacement.

Recommended intervals for secondary air filter, housing, and valve replacement.