Image Adjustment

191

Adjustment Procedure

1. Enter SP2-109-003.

2. Print out the test pattern (14: 1-dot trimming pattern) with SP2-109-003.

• Registration can change slightly as shown on the previous page. Print some pages of the 1-dot

trimming pattern for steps 3 and 4. Then average the leading edge and side-to-side registration

values, and adjust each SP mode.

3. Do the leading edge registration adjustment.

1) Check the leading edge registration and adjust it with SP1-001.

2) Select the adjustment conditions (paper type and process line speed).

3) Input the value. Then press [#].

4) Generate a trim pattern to check the leading edge adjustment.

4. Do the side-to-side registration adjustment.

1) Check the side-to-side registration and adjust it with SP1-002.

2) Select the adjustment conditions (paper feed station).

3) Input the value. Then press [#].

4) Generate a trim pattern to check the side-to-side registration adjustment.

Erase Margin Adjustment

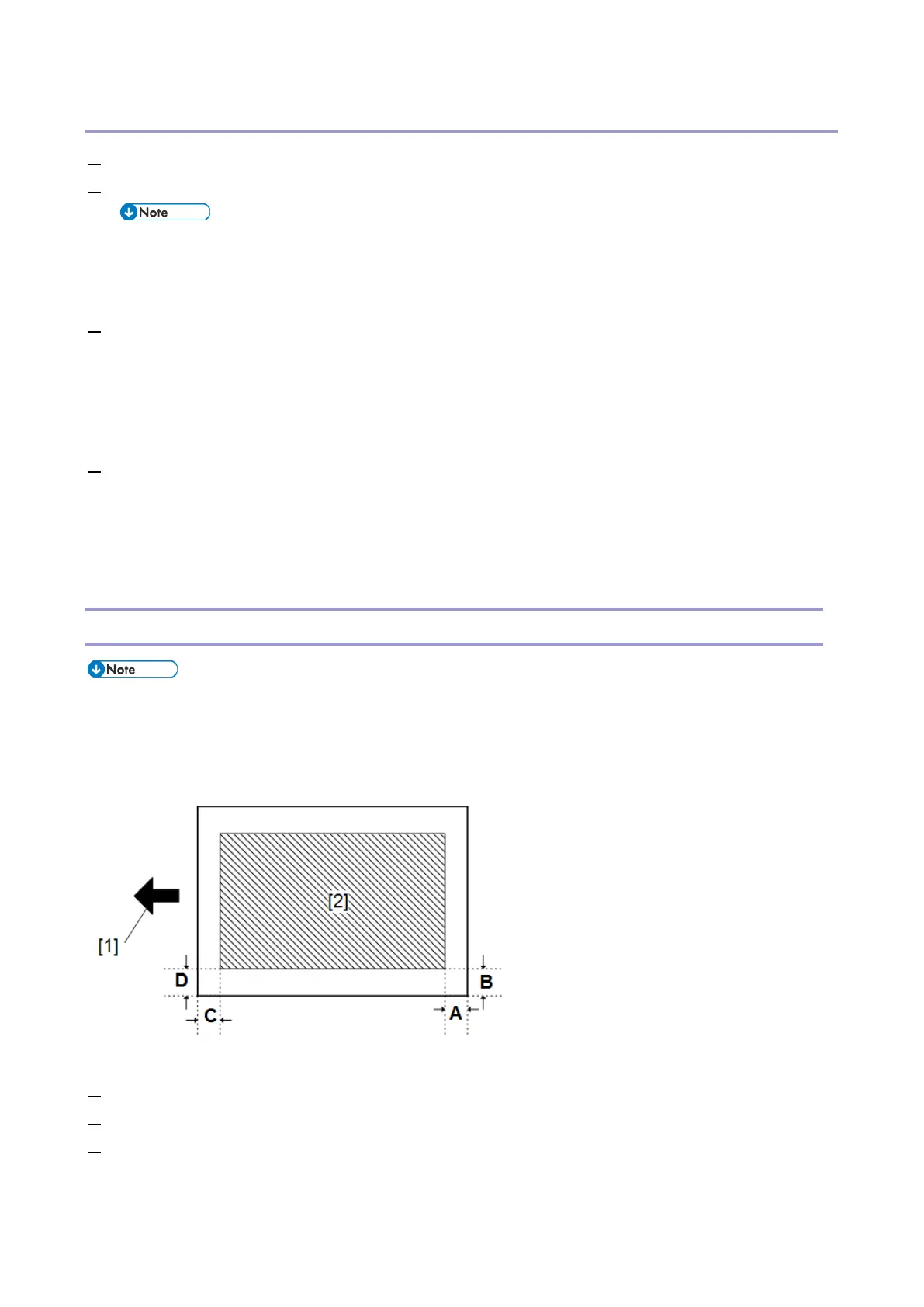

• After adjusting the Leading Edge Registration and Side Registration settings (see the previous

section), do the Erase Margin Adjustment. To do this, check the values of Margins A and B.

• If they are not within the specifications (see below), then adjust A and B with SP2-103-001 to -004 as

explained below. Then check Margins C and D again.

[1]: Feed direction, [2]: Image area

1. Enter the SP mode.

2. Print out the test pattern (14: 1-dot trimming pattern) with SP2-109-003.

3. Check the erase margin A and B. Adjust them with SP2-103-001 to -004 if necessary.

• Leading edge: 0.0 to 9.9 mm (default: 4.2 mm)

• Side-to-side: 0.0 to 9.9 mm (default: 2.0 mm)

Loading...

Loading...