Groundsmaster 4300--D Page 5 -- 27 Electrical System

Seat Switch

The s eat switch is normally open and closes when the

operator seat is occupied. This switch is used as an in-

put for the TEC controller. If the traction system or PTO

switch is engaged when the operator raises out of the

seat, the engine will stop. The seat switch is located di-

rectly under the operator seat.

Testing

1. Before disconnecting the seat switch for testing, the

switch and its circuit wiring should be tested as a TEC

controller input with the Diagnostic Display (see Diag-

nostic D isplay in the Troubleshooting section of this

chapter). If the Diagnostic Display verifies that the seat

switchandcircuitwiringarefunctioningcorrectly,nofur-

ther switch testing is necessary. If, however, the Diag-

nostic D isplay determines that the seat switch and

circuitwiring arenot functioningcorrectly,proceedwith

test procedure.

2. Make sure ignition switch is in the OFF position.

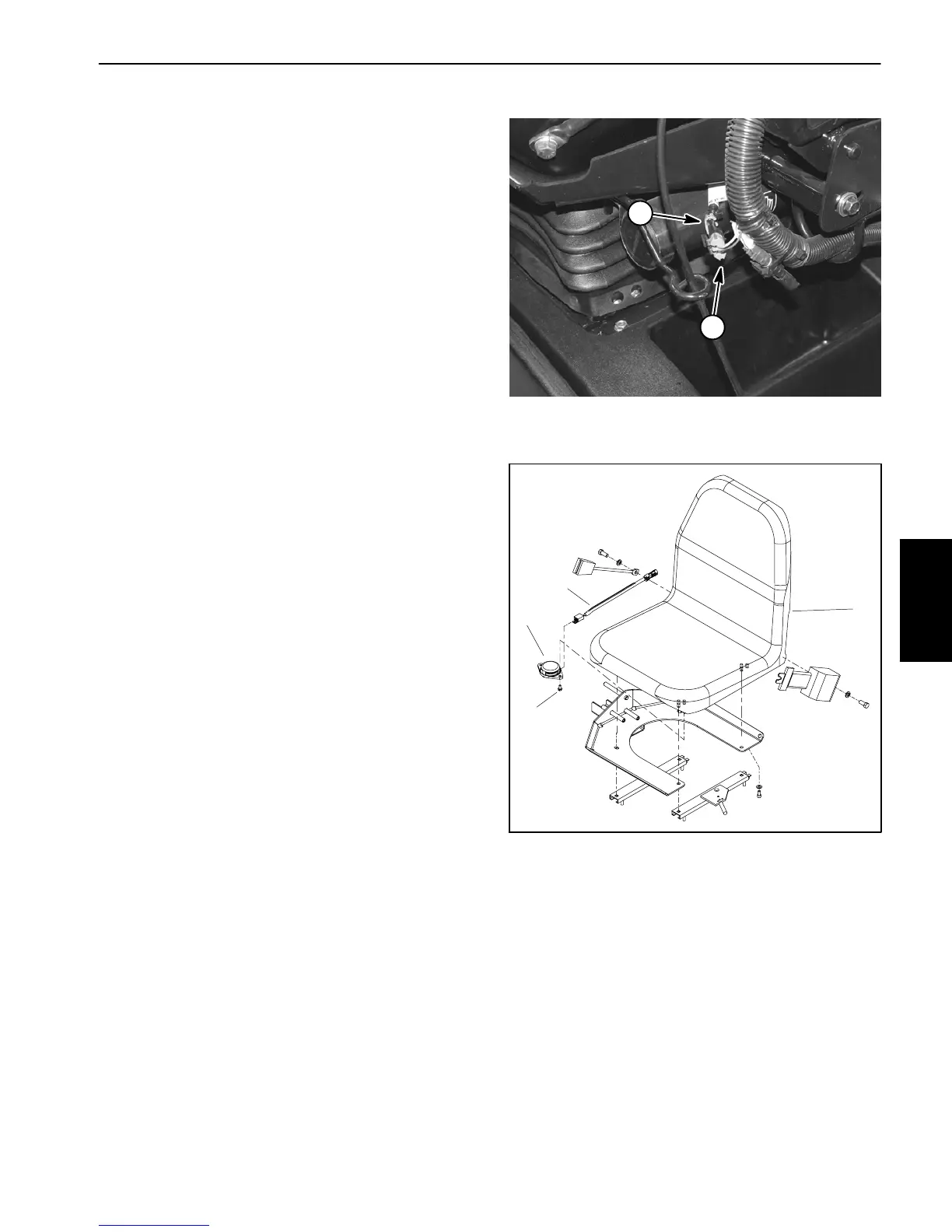

3. Disconnect wire harness electrical connector from

theseat switchelectricallead nearthe operatormanual

tube under the operator seat (Fig. 27).

4. Check the continuity of the switch by connecting a

multimeter (ohms setting) across the switch connector

terminals.

5. With no pressure on the seat, there should be no

continuity (open) between the seat switch terminals.

6. Press directly onto the seat switch through the seat

cushion.Thereshouldbec ontinuity(closed)astheseat

cushion approaches the bottom of its travel.

7. If seat switch is faulty, replace switch (see Operator

Seat Removal in the Service and Repairs section of

Chapter 6 -- Chassis).

8. Iftheseatswitchtestscorrectlyandacircuitproblem

stillexists,checkwire harness(seeElectricalSchemat-

ic and Circuit Drawings in Chapter 8 -- Foldout Draw-

ings).

9. Connect wire harness electrical connector to the

seat switch electrical lead.

1. Seat switch lead 2. Electrical connector

Figure 27

1

2

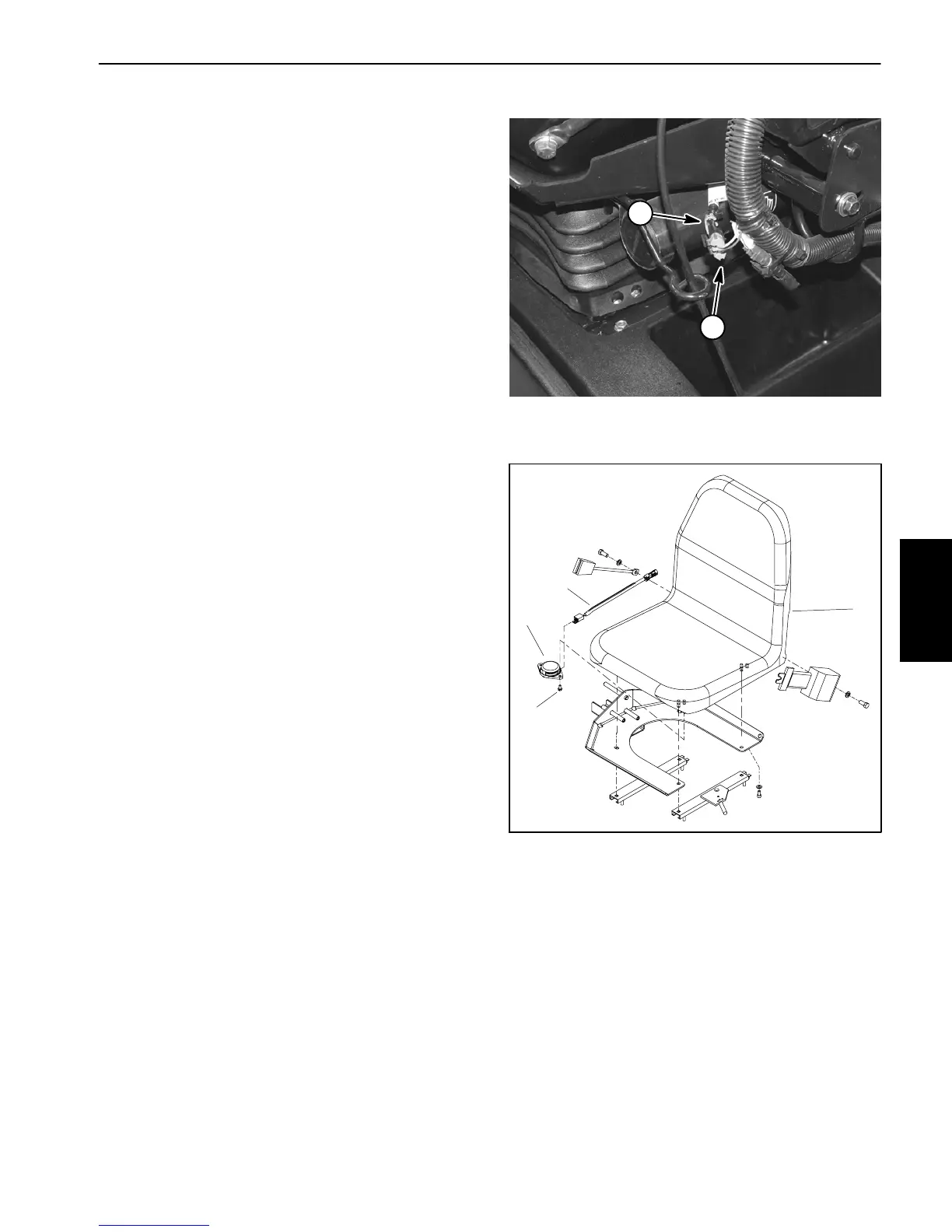

1. Operator seat

2. Seat switch

3. Screw (2 used)

4. Seat wire harness

Figure 28

2

3

4

1

Electrical

System

Loading...

Loading...