Groundsmaster 4300--DPage 5 -- 40Electrical System

High Temperature Shutdown Switch

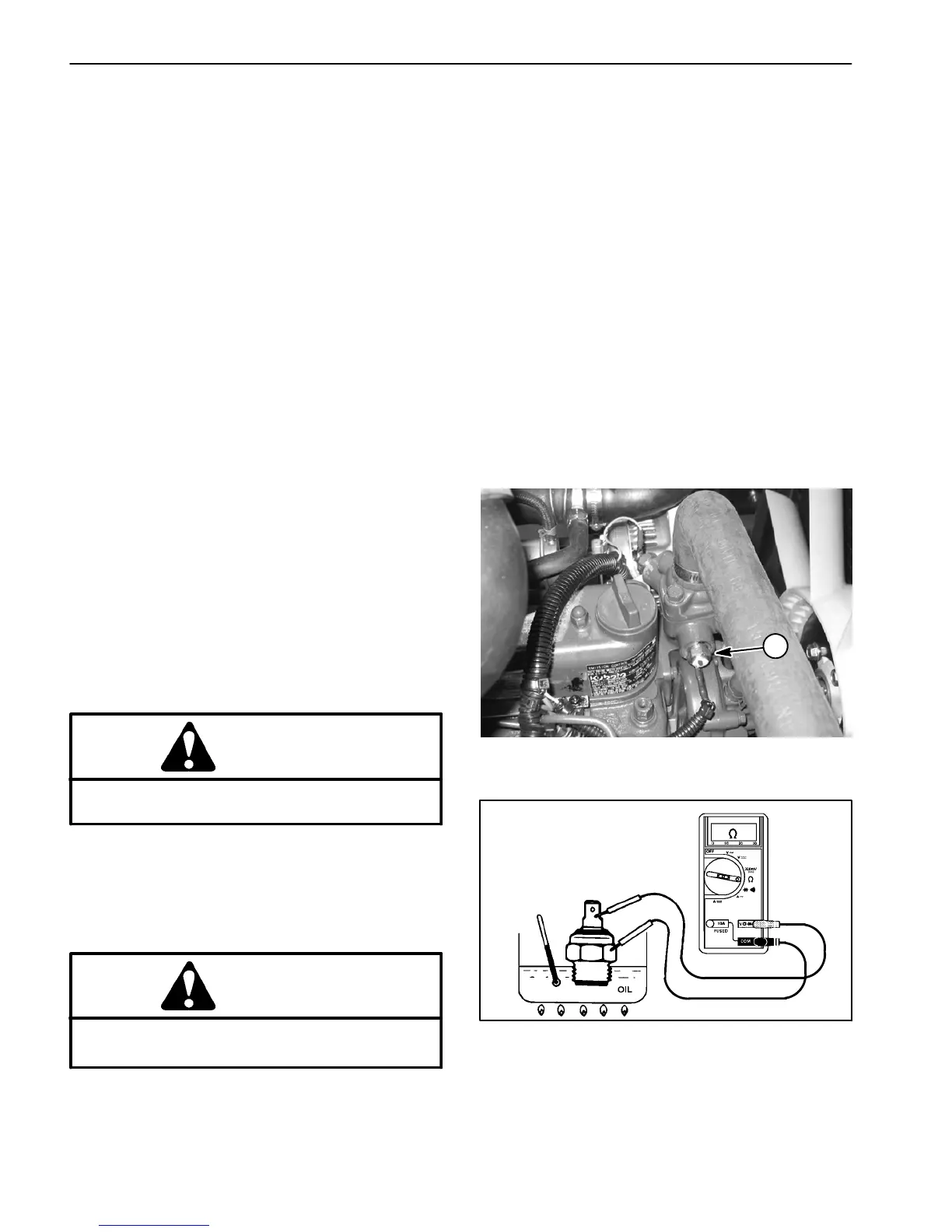

Thehightemperatureshutdownswitchislocatedonthe

water pump housing ( Fig. 50). The high temperature

shutdown switch is normallyopen and closes when en-

ginecoolanttemperaturer eaches approximately239

o

F

(115

o

C). When excessive coolant temperature c auses

the shutdown switch to close, the engine shuts down.

There is a tan wire attached to the shutdown switch.

NOTE: If excessive coolant temperature causes en-

gineshutdown,theoperatorcanrestarttheenginetoal-

low the machine to be moved a short distance. After a

restart in this condition, the engine will run for approxi-

mately ten (10) seconds before the engine shuts down

again.

The TEC controller monitors the operation of the high

temperatureshutdown switch.The switchandits circuit

wiring should be tested as a controller input with the

Diagnostic Display (see Special Tools and Trouble-

shooting in this chapter).

If excessive coolant temperature caused the TEC con-

troller to shut down the engine, the Diagnostic light can

be used to identify the fault (see Diagnostic Light in the

Troubleshooting section of this chapter).

Testing

1. Park machine on a level s urface, lower cutting

decks, stop engine, apply parking brake and remove

keyfromignitionswitch.Open andsupporthoodtogain

access to engine.

CAUTION

Make sure engine is cool before removing the

temperature switch from engine.

2. Lowerthecoolantlevelintheengineandremovethe

high temperature shutdown switch from the engine.

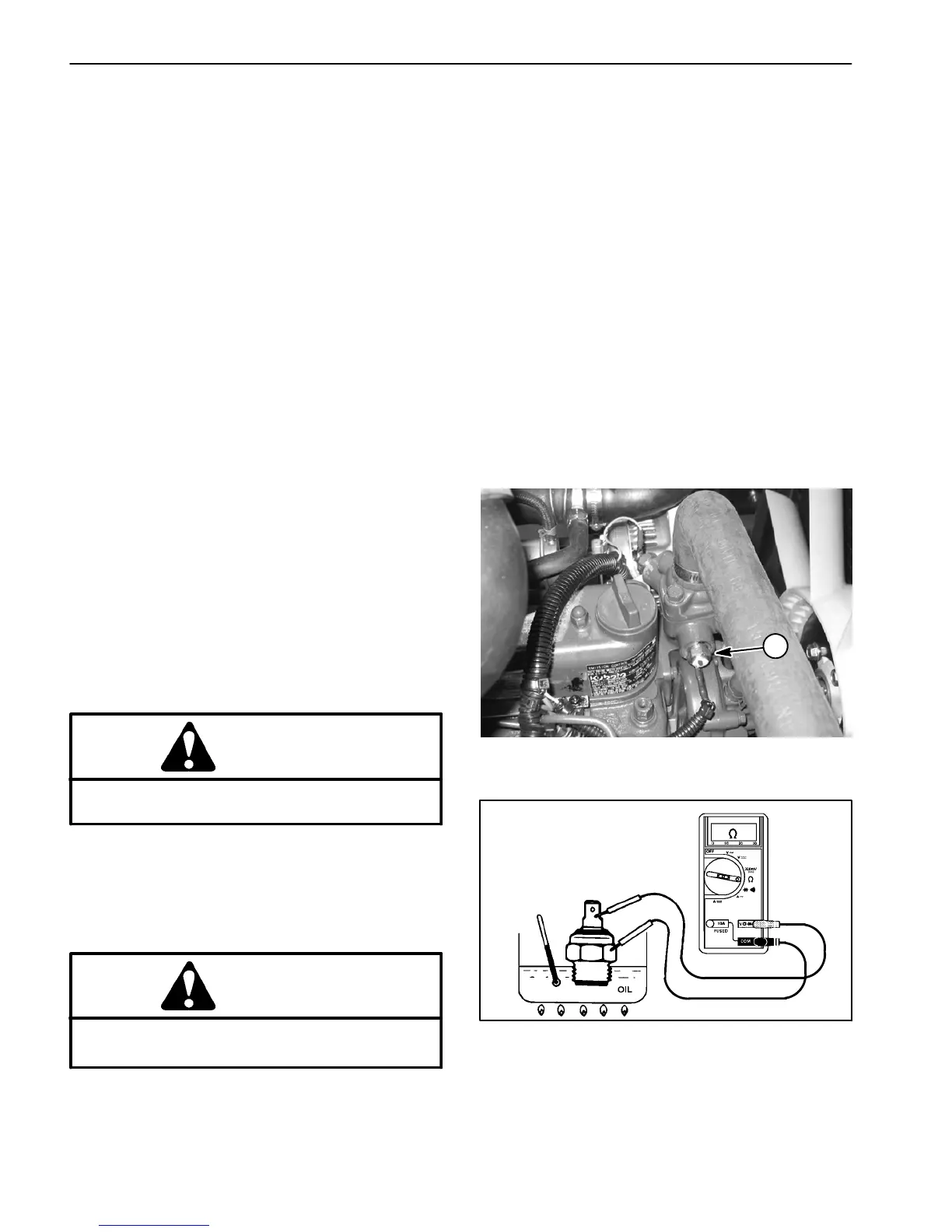

3. Put the end of the switch in a container of oil with a

thermometer and slowly heat the oil (Fig. 51).

CAUTION

Handle the hot oil with extreme care to prevent

personal injury or fire.

4. Check resistance of the switch with a multimeter

(ohms setting) as the oil temperature increases. The

hightemperatureshutdownswitchisnormallyopenand

should close from 234

o

to 244

o

F(112

o

to 118

o

C).

5. Replace shutdown switch if specifications are not

met.

6. After testing is complete, install shutdown switch to

the engine housing.

A. Clean threads of housing and switch thoroughly.

Apply alight coating ofthread sealantto the threads

of the switch.

B. Thread switch into the housing. Torque switch

from 22 to 28 ft--lb (30 to 39 N--m).

C. Reconnect harness wire to switch.

7. Fill engine cooling system (see Radiator Installation

intheServiceandRepairssectionofChapter3--Kubota

Diesel Engine).

8. Lower and secure hood.

1. High temperature shutdown switch

Figure 50

1

Figure 51

Loading...

Loading...