2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES–225

ES

MONITOR DESCRIPTION

The knock sensor, located on the cylinder block, detects spark knock. When spark knock occurs, the

piezoelectric element of the sensor vibrates. When the ECM detects a voltage in this frequency range, it

retards the ignition timing to suppress spark knock.

The ECM also senses background engine noise with the knock sensor and uses this noise to check for

faults in the sensor. If the knock sensor signal level is too low for more than 10 seconds, or if the knock

sensor output voltage is outside the normal range, the ECM interprets this as a fault in the knock sensor

and sets a DTC.

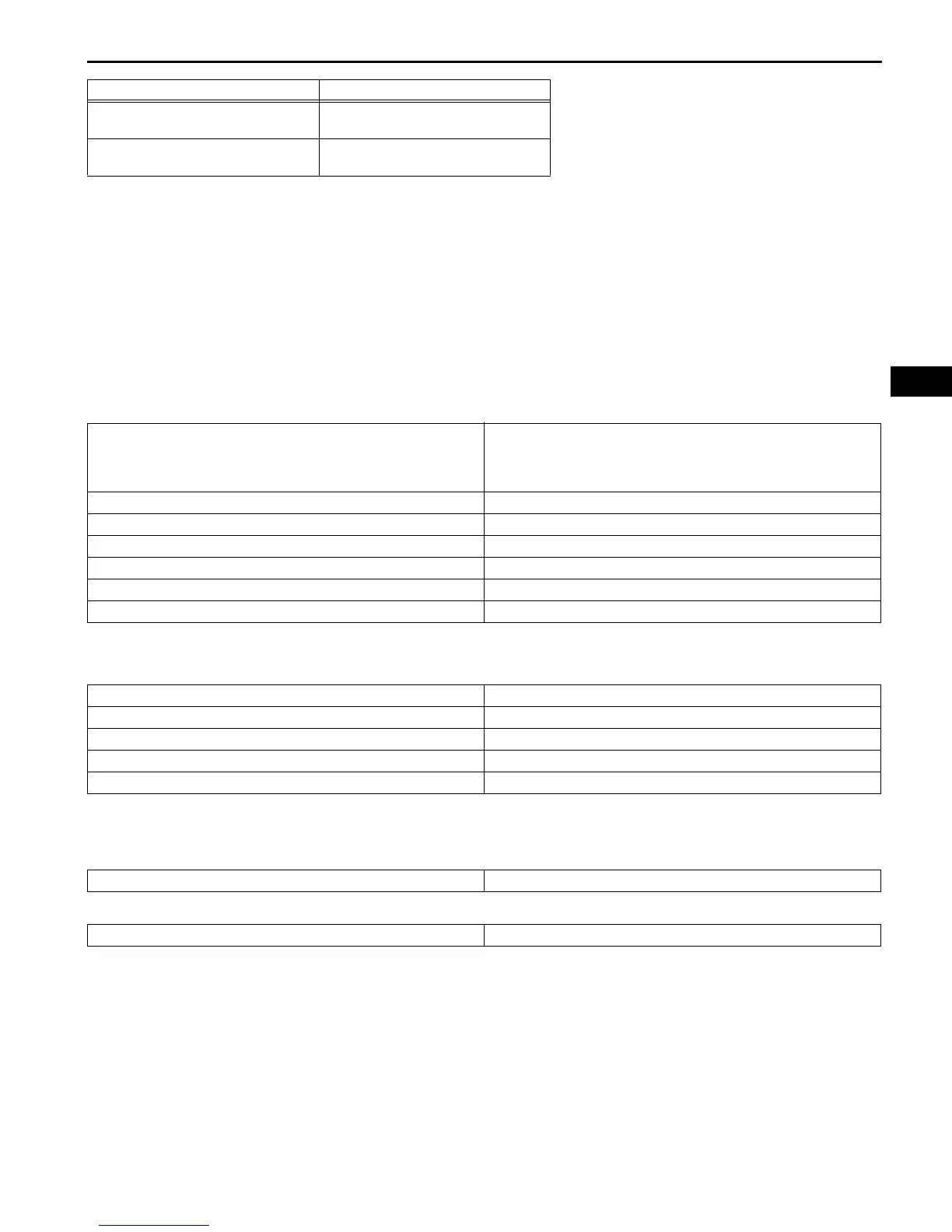

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

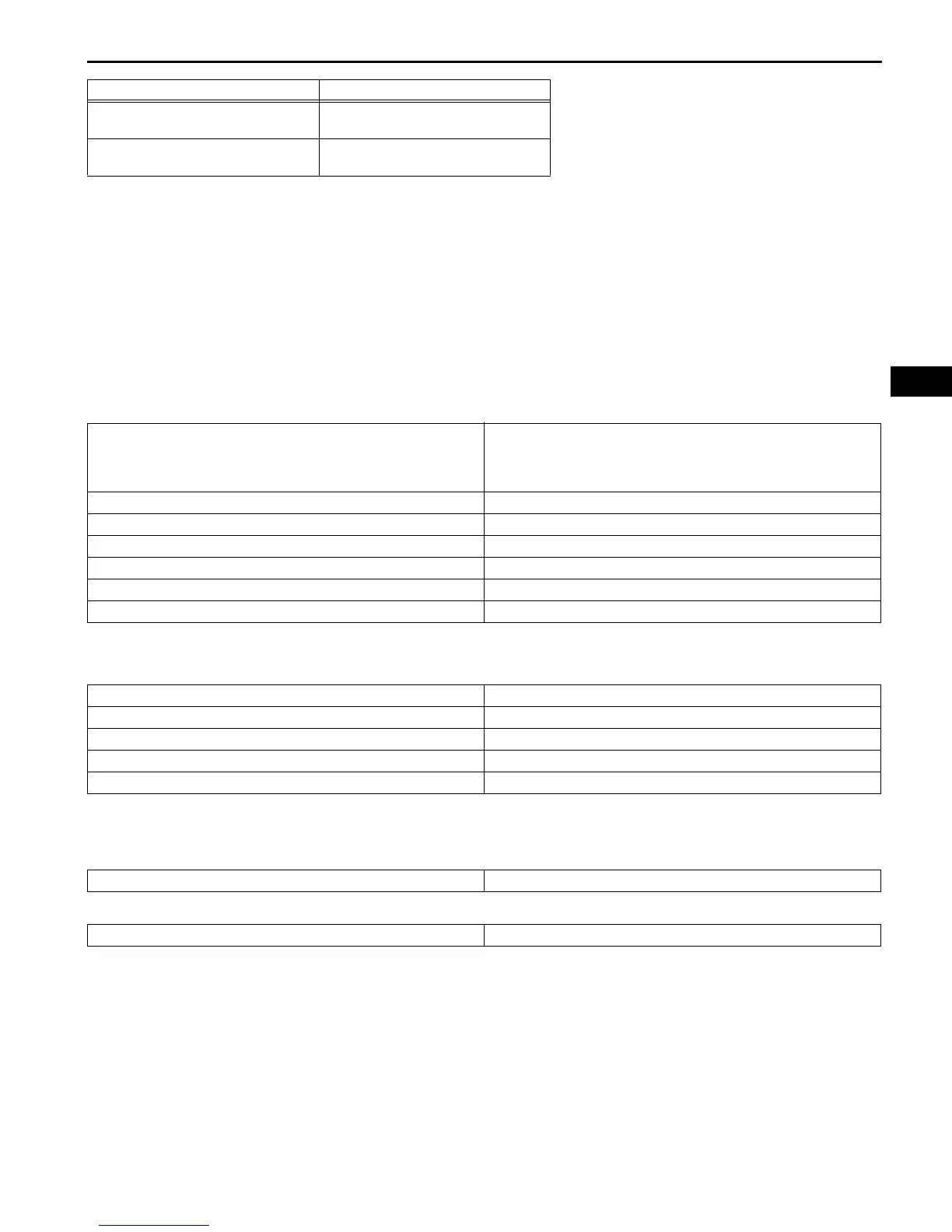

TYPICAL MALFUNCTION THRESHOLDS

Knock Sensor Range Check (Low voltage) P0327 and P0332:

Knock Sensor Range Check (High voltage) P0328 and P0333:

Equipment Settings

0.01 to 10 V/DIV.

0.01 to 10 ms./DIV.

Conditions

Keep engine speed at 4,000 rpm with

warm engine

Related DTCs

P0327: Knock sensor (Bank 1) open/short (Low voltage)

P0328: Knock sensor (Bank 1) open/short (High voltage)

P0332: Knock sensor (Bank 2) open/short (Low voltage)

P0333: Knock sensor (Bank 2) open/short (High voltage)

Required Sensors/Components (Main) Knock sensor (Bank 1 and 2)

Required Sensors/Components (Related) -

Frequency of Operation Continuous

Duration 1 second

MIL Operation Immediate

Sequence of Operation None

Monitor runs whenever following DTCs are not present None

Battery voltage 10.5 V or more

Time after engine start 5 seconds or more

Engine switch ON

Starter OFF

Knock sensor voltage Less than 0.5 V

Knock sensor voltage More than 4.5 V

Item Content

Loading...

Loading...