EM–88

2GR-FE ENGINE MECHANICAL – ENGINE UNIT

EM

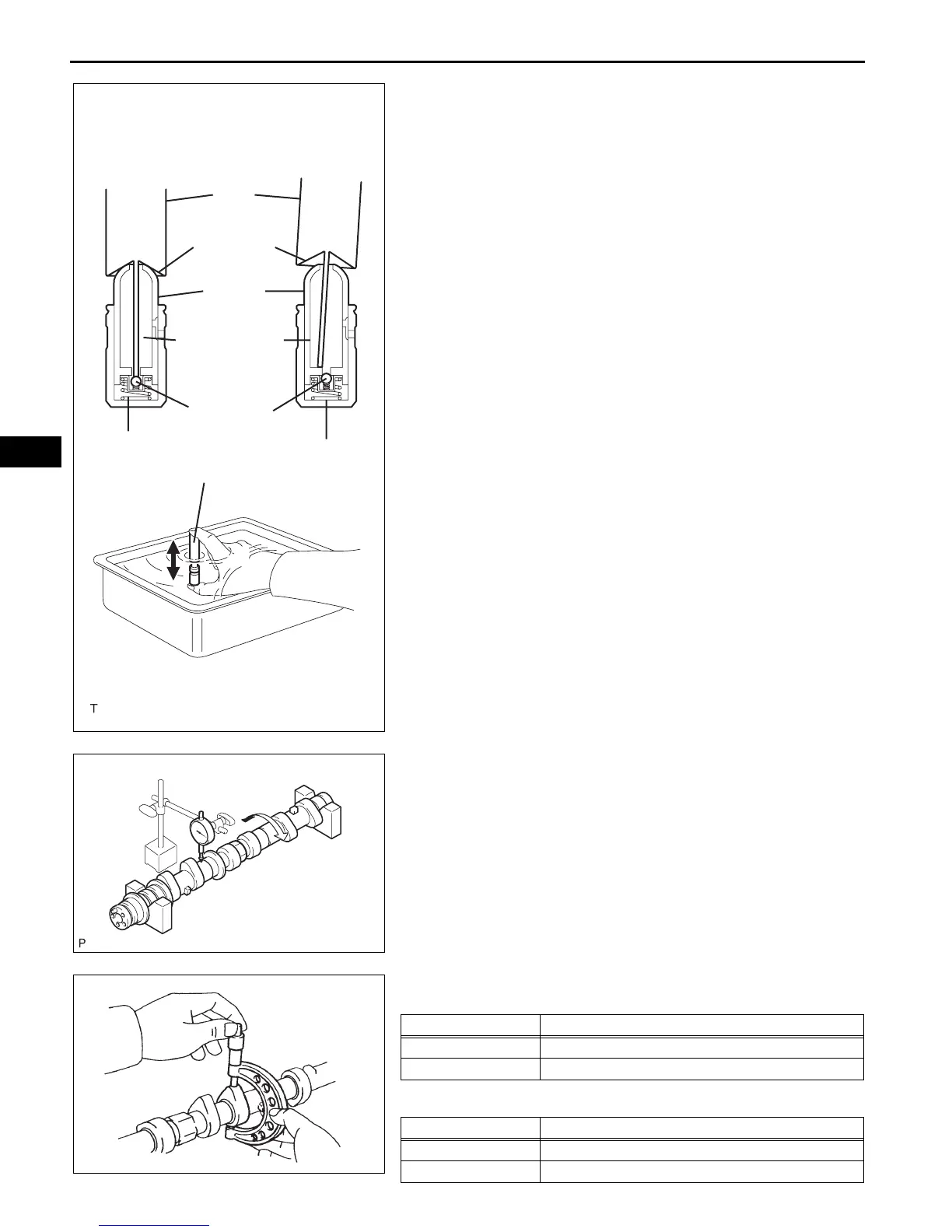

(b) Insert the SST's tip into the lash adjuster's plunger

and use the tip to press down on the check ball

inside the plunger.

SST 09276-75010

(c) Squeeze the SST and lash adjuster together to

move the plunger up and down 5 to 6 times.

(d) Check the movement of the plunger and bleed the

air.

OK:

Plunger moves up and down.

NOTICE:

When bleeding air from the high-pressure

chamber, make sure that the tip of the SST is

actually pressing the check ball as shown in the

illustration. If the check ball is not pressed, air

will not bleed.

(e) After bleeding the air, remove the SST. Then try to

quickly and firmly press the plunger with a finger.

OK:

Plunger is very difficult to move.

If the result is not as specified, replace the lash

adjuster.

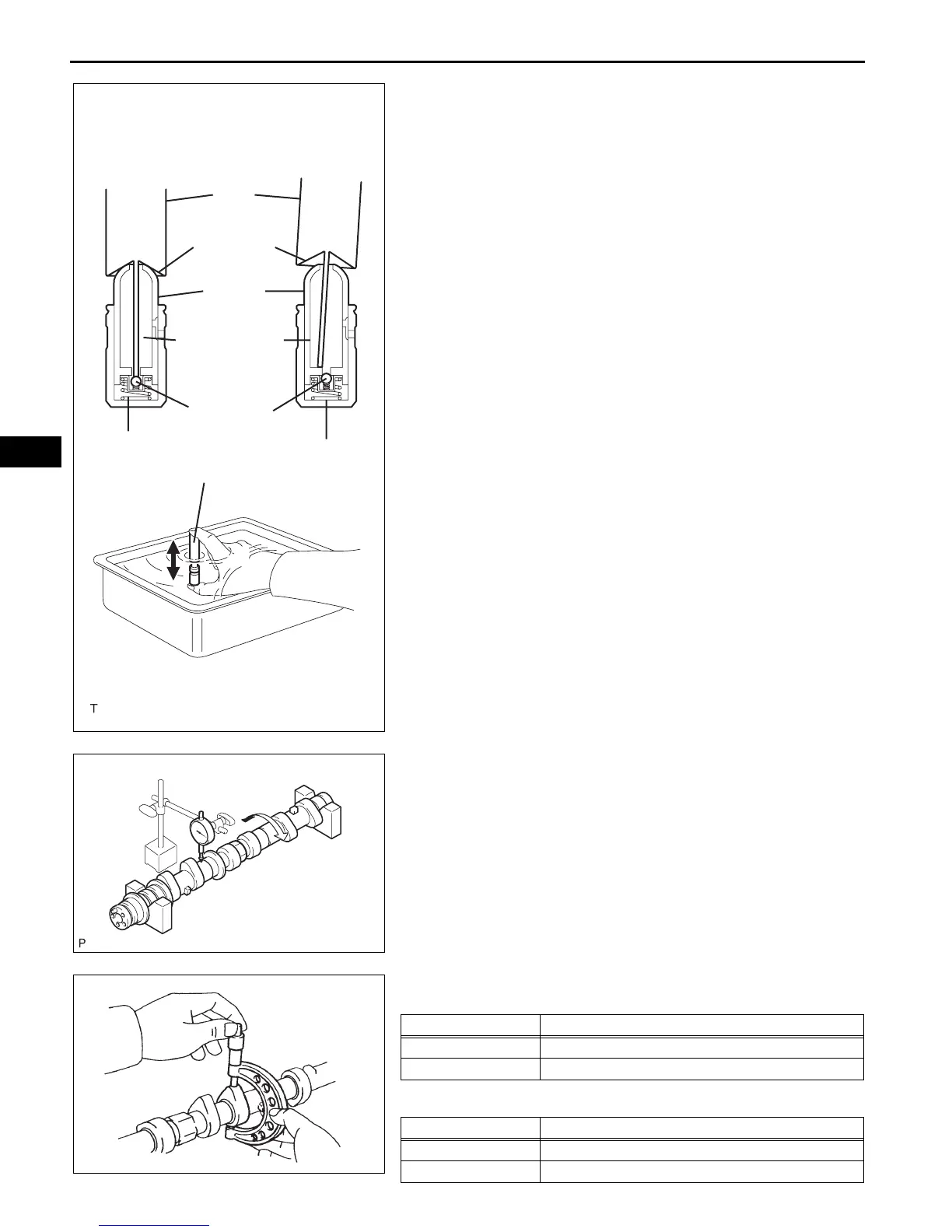

3. INSPECT CAMSHAFT

(a) Inspect the camshaft for runout.

(1) Place the camshaft on V-blocks.

(2) Using a dial indicator, measure the circle runout

at the center journal.

Maximum circle runout:

0.04 mm (0.0016 in.)

If the circle runout is greater than the

maximum, replace the camshaft.

HINT:

Check the oil clearance after replacing the

camshaft.

(b) Using a micrometer, measure the cam lobe height.

Standard cam lobe height

Maximum cam lobe height

CORRECT

INCORRECT

SST

SST

Taper Part

Check Ball

Low Pressure

Chamber

High Pressure

Chamber

High Pressure

Chamber

Plunger

A109630E01

A120669

A109632

Item Specification

Intake camshaft 44.316 to 44.416 mm (1.7447 to 1.7487 in.)

Exhaust camshaft 44.262 to 44.362 mm (1.7426 to 1.7465 in.)

Item Specification

Intake camshaft 44.166 mm (1.7388 in.)

Exhaust camshaft 44.112 mm (1.7367 in.)

Loading...

Loading...