ES–252

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

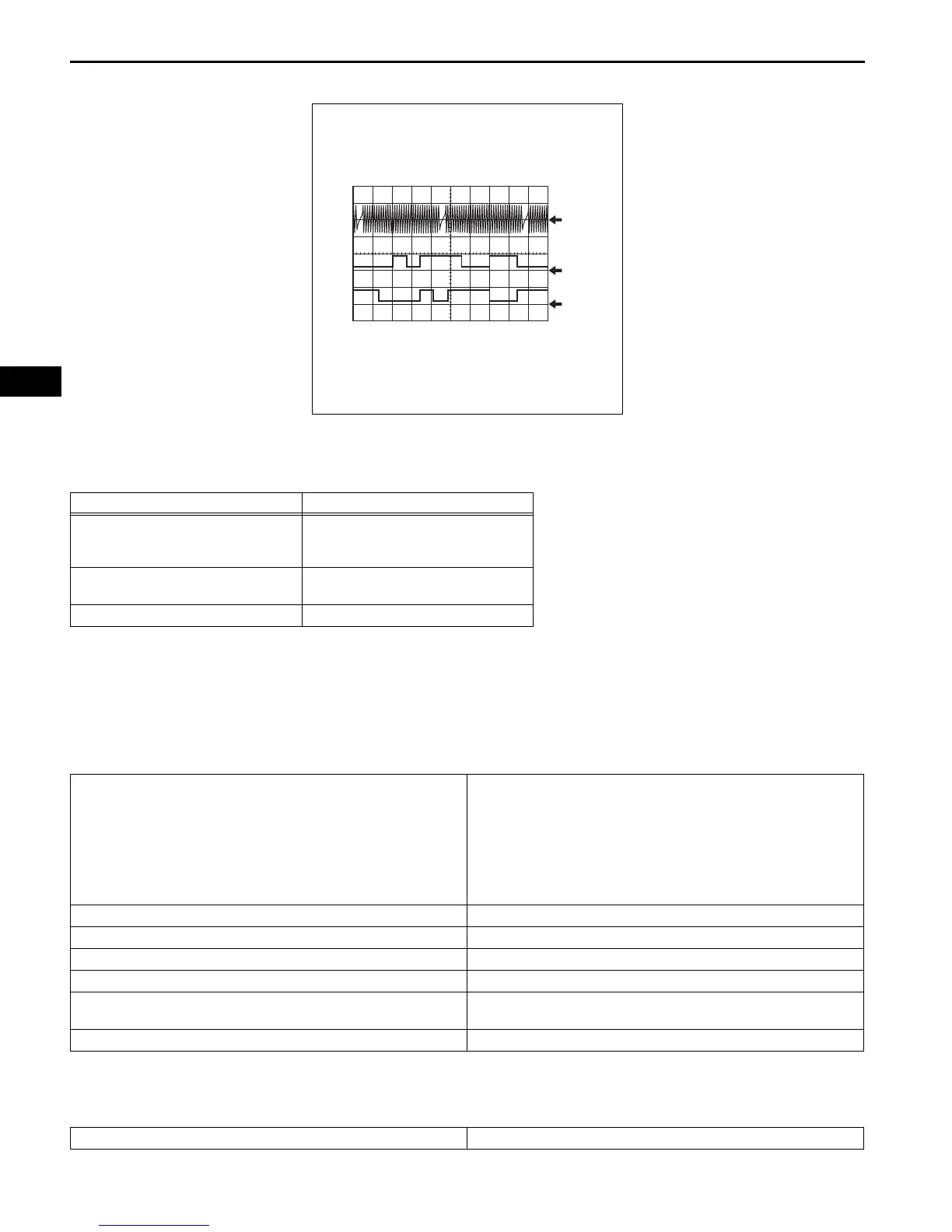

Reference: Inspection using an oscilloscope

HINT:

• The correct waveform is as shown.

• EV1+ and EV2+ stand for the VVT sensor signal, and NE+ stands for the CKP sensor signal.

MONITOR DESCRIPTION

If no signal is transmitted by the VVT sensor despite the engine revolving, or the rotations of the camshaft

and the crankshaft are not synchronized, the ECM interprets this as a malfunction of the sensor.

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

All:

Item Content

Terminal

NE+ - NE-

EV1+ - EV1-

EV2+ - EV2-

Equipment Setting

5 V/DIV.

20 ms./DIV.

Condition Cranking or idling

Related DTCs

P0365: VVT sensor (Bank 1) open/short

P0365: VVT position/Crankshaft position misalignment (Bank 1)

P0367: VVT position sensor (Bank 1) range check (low voltage)

P0368: VVT position sensor (Bank 1) range check (high voltage)

P0390: VVT sensor (Bank 2) open/short

P0390: VVT position/Crankshaft position misalignment (Bank 2)

P0392: VVT position sensor (Bank 2) range check (low voltage)

P0393: VVT position sensor (Bank 2) range check (high voltage)

Required Sensors/Components (Main) VVT position sensor (Bank 1 and 2)

Required Sensors/Components (Sub) Crankshaft position sensor

Frequency of Operation Continuous

Duration 5 seconds

MIL Operation

2 driving cycles: P0365, P0390 (cranking)

Immediate: Others

Sequence of Operation None

Monitor runs whenever following DTCs are not present None

EV1, EV2 and NE Signal Waveform

NE

EV1

EV2

GND

GND

GND

5 V/DIV.

20 ms./DIV.

A140642E02

Loading...

Loading...