ENGl NE MECHANICAL

-

Com~ression Check

COMPRESSION CHECK

HINT:

If there

is

lack of power, excessive oil consump-

tion or poor fuel economy, measure the compression pres-

sure.

WARM UP AND STOP ENGINE

Allow the engine to reach normal operating temperature.

DISCONNECT INJECTION PUMP (FUEL CUT

SOLENOID) CONNECTOR

REMOVE AIR CLEANER

(w/

Intake Pipe)

REMOVE INTAKE PIPE

REMOVE GLOW PLUGS

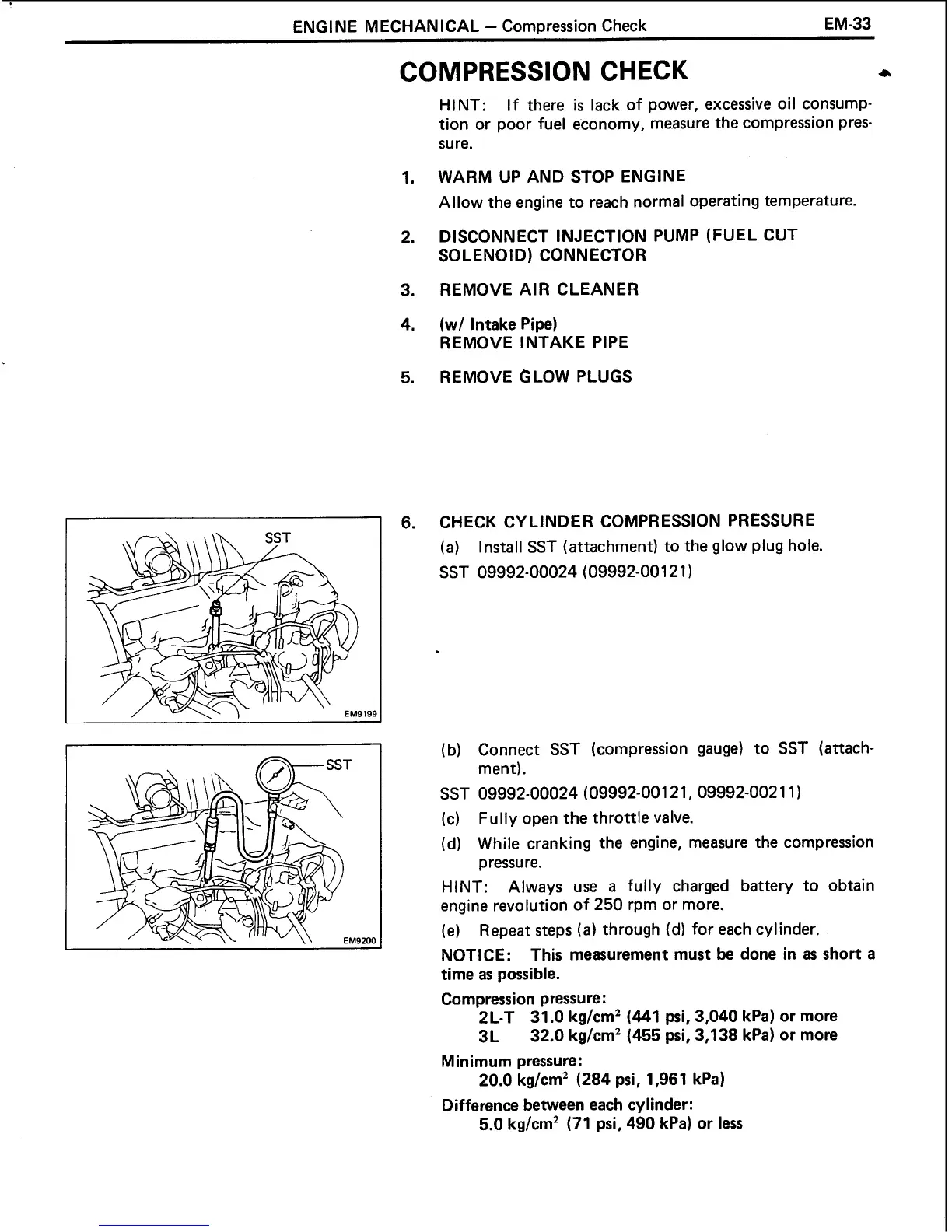

CHECK CYLINDER COMPRESSION PRESSURE

(a)

Install SST (attachment) to the glow plug hole.

SST 09992-00024 (09992-001 2

1

)

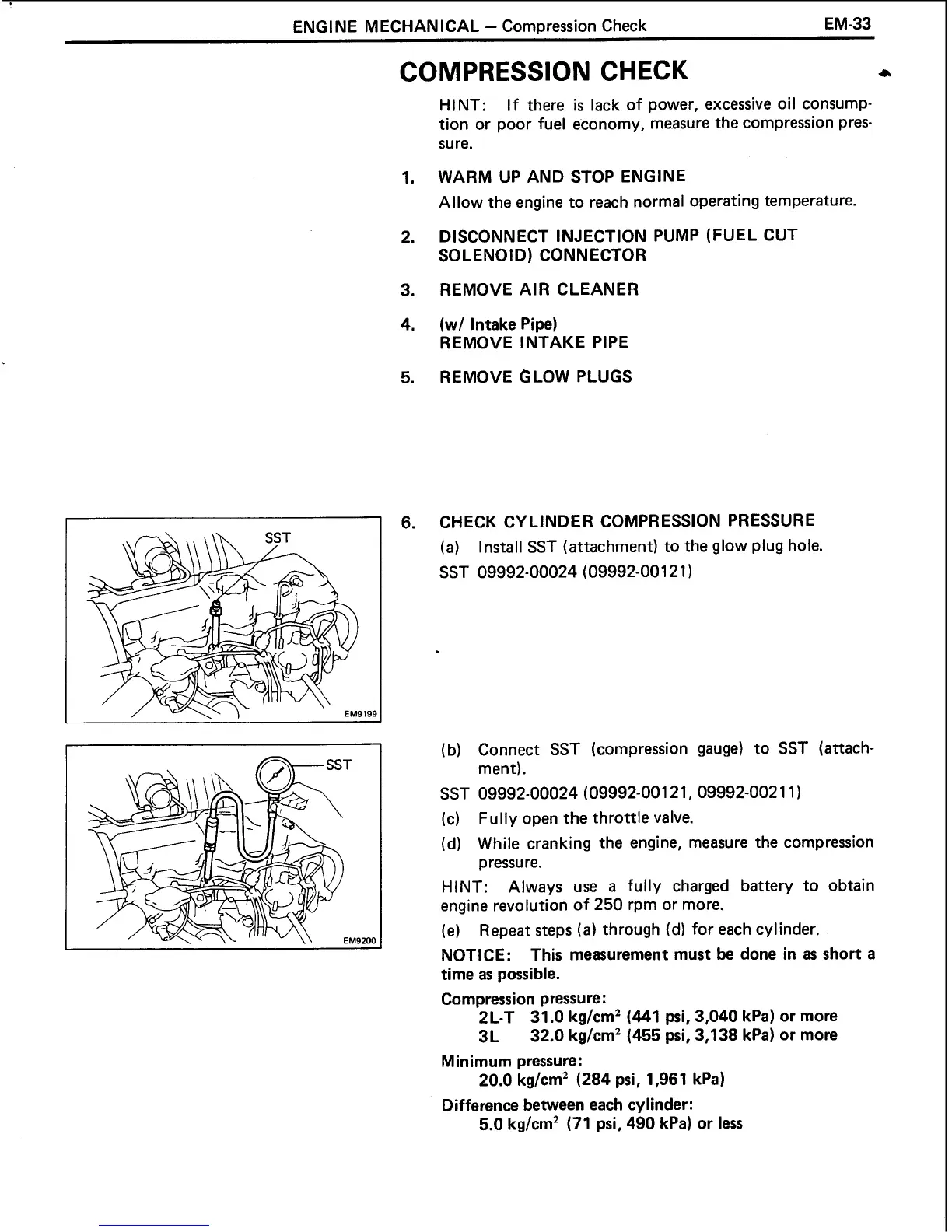

(b) Connect SST (compression gauge) to SST (attach-

ment).

SST 09992-00024 (09992-00 1 2 1,09992-002 1 1

)

(c)

Fully open the throttle valve.

(d) While cranking the engine, measure the compression

pressure.

HINT: Always use

a

fully charged battery to obtain

engine revolution of 250 rpm or more.

(e)

Repeat steps (a) through (d) for each cylinder.

NOTICE:

This measurement must be done in

as

short a

time as possible.

Compression pressure:

2L-T 31.0 kg/cm2

(441

psi, 3,040 kPa) or more

3L 32.0 kg/cm2 (455 psi, 3,138 kPa) or more

Minimum pressure:

20.0 kg/cm2 (284 psi,

1,961 kPa)

Difference between each cylinder:

5.0 kg/cm2 (71 psi, 490 kPa) or less

Loading...

Loading...