1

ENGINE MECHANICAL

-

Cylinder Block

EM-49

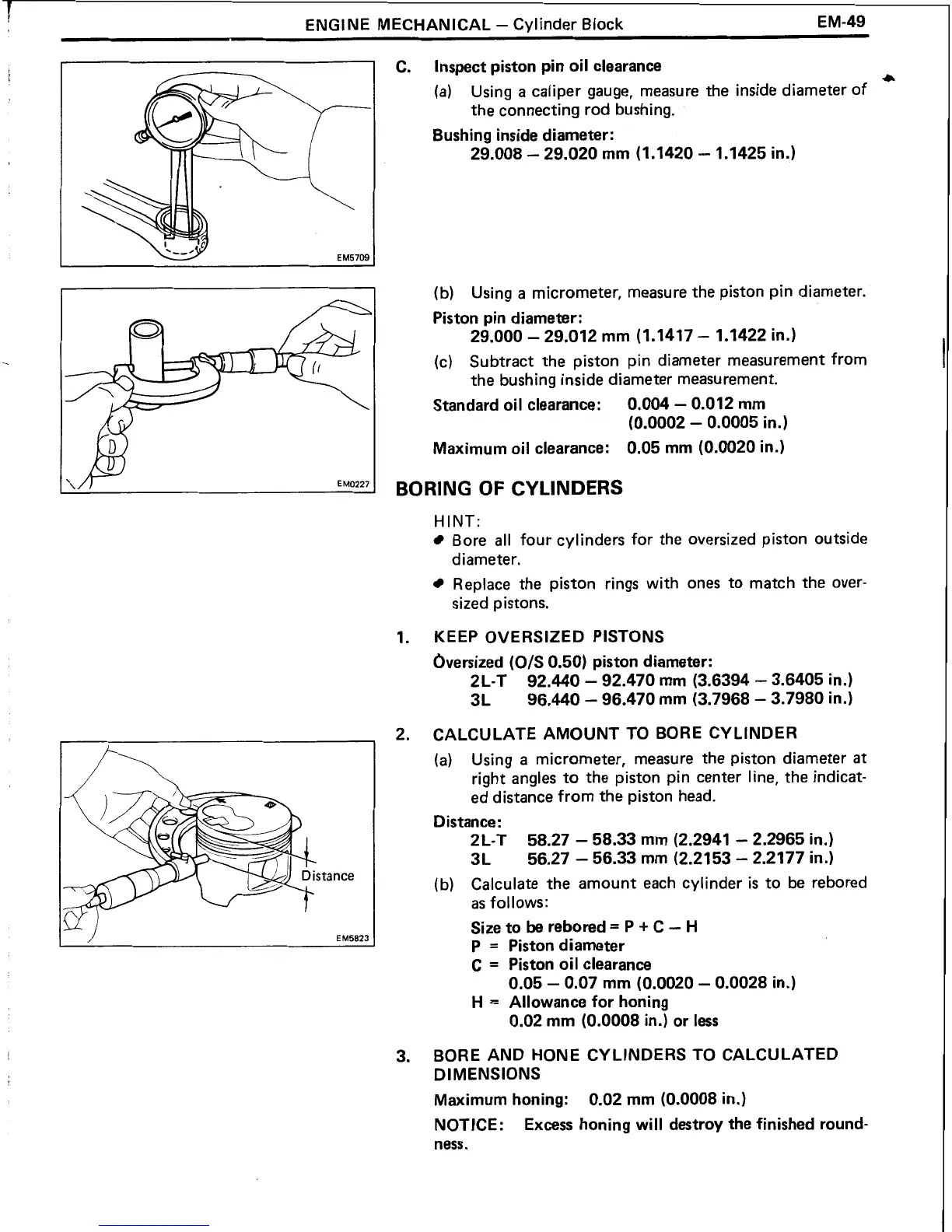

C. Inspect piston pin oil clearance

a

(a)

Using

a

caliper gauge, measure the inside diameter of

the connecting rod bushing.

Bushing inside diameter:

29.008

-

29.020 mm (1.1420

-

1.1425 in.)

tance

(b)

Using

a

micrometer, measure the piston pin diameter.

Piston pin diameter:

29.000

-

29.012 mm (1.1417

-

1.1422 in.)

(c)

Subtract the piston pin diameter measurement from

the bushing inside diameter measurement.

I

Standard oil clearance:

0.004

-

0.012 mm

(0.0002

-

0.0005 in.)

Maximum oil clearance:

0.05 mm (0.0020 in.)

BORING

OF CYLINDERS

HINT:

Bore all four cylinders for the oversized piston outside

diameter.

Replace the piston rings with ones to match the over-

sized pistons.

KEEP OVERSIZED PISTONS

Oversized

(01s 0.50) piston diameter:

2L-T

92.440

-

92.470 mm (3.6394

-

3.6405 in.)

3L

96.440

-

96.470 mm (3.7968

-

3.7980 in.)

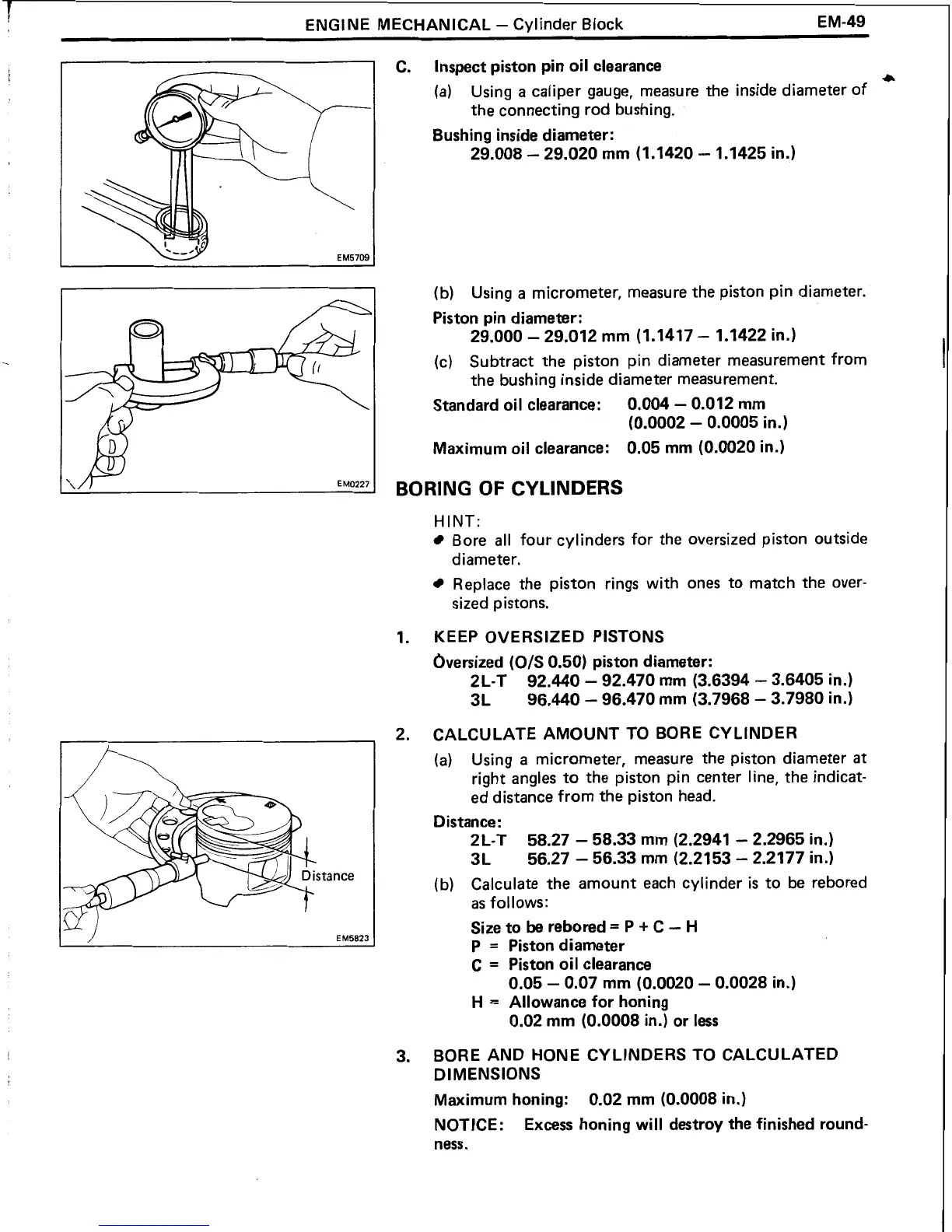

CALCULATE AMOUNT TO BORE CYLINDER

(a)

Using

a

micrometer, measure the piston diameter

at

right angles to the piston pin center line, the indicat-

ed distance from the piston head.

Distance:

2L-T

58.27

-

58.33 mm (2.2941

-

2.2965 in.)

3L

56.27

-

56.33 mm (2.2153

-

2.2177 in.)

(b) Calculate the amount each cylinder

is

to

be

rebored

as

follows:

Size to

be

rebored

=

P

+

C

-

H

P

=

Piston diameter

C

=

Piston oil clearance

0.05

-

0.07 mm (0.0020

-

0.0028 in.)

H

=

Allowance for honing

0.02 mm (0.0008 in.) or less

BORE AND HONE CYLINDERS TO CALCULATED

DIMENSIONS

Maximum honing:

0.02 mm (0.0008 in.)

NOTICE:

Excess honing will destroy the finished round-

ness.

Loading...

Loading...