FU-16

FUEL SYSTEM

-

Injection Pum~

ASSEMBLY

OF

INJECTION

PUMP

(See

pages

FU-6

to

8)

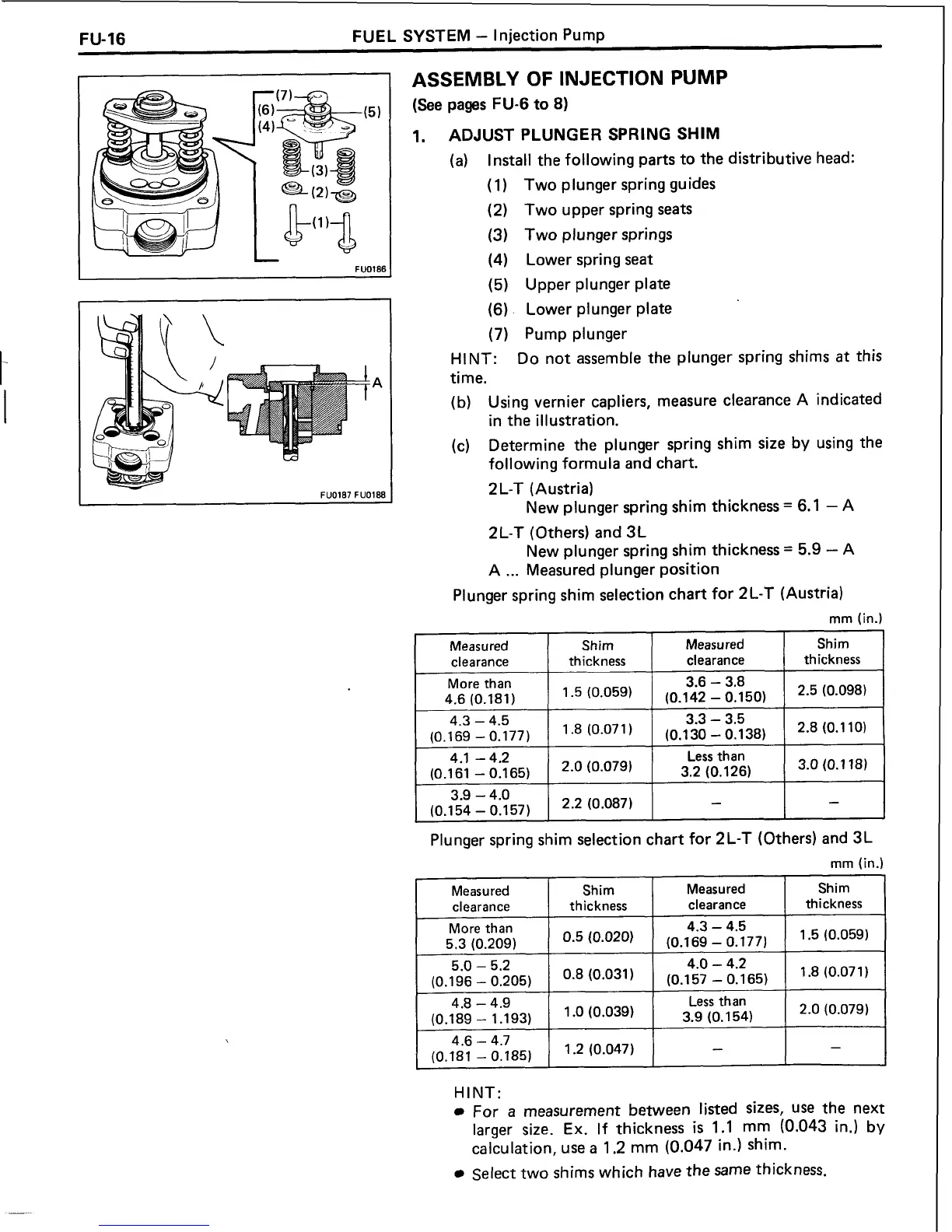

1. ADJUST PLUNGER SPRING SHIM

(a)

Install the following parts to the distributive head:

(1) Two plunger spring guides

(2) Two upper spring seats

(3) Two plunger springs

(4)

Lower spring seat

(5) Upper plunger plate

(6) Lower plunger plate

(7) Pump plunger

HINT:

Do not assemble the plunger spring shims

at

this

time.

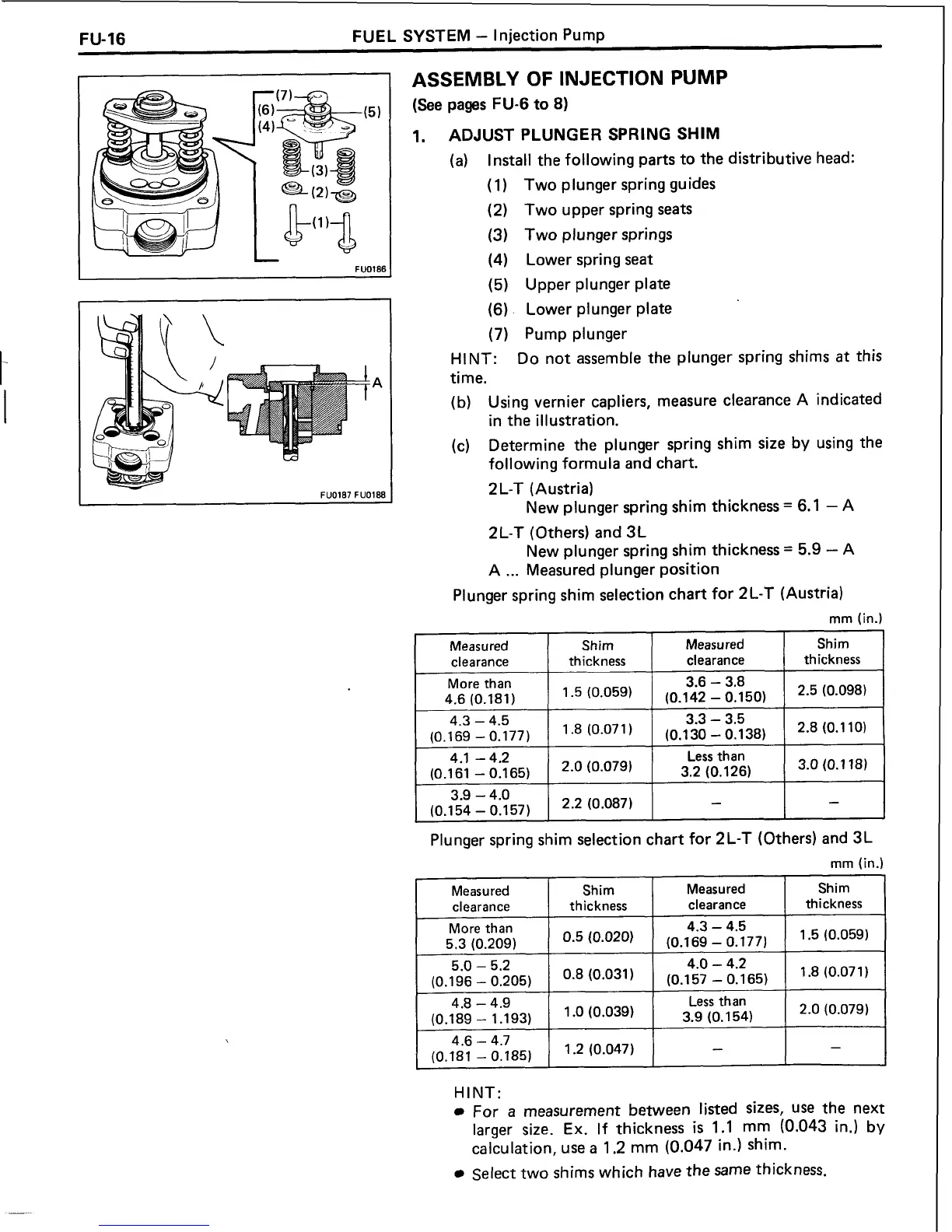

(b)

Using vernier capliers, measure clearance A indicated

in the illustration.

(c)

Determine the plunger spring shim size

by

using the

following formula and chart.

2L-T (Austria)

New plunger spring shim thickness

=

6.1

-

A

2L-T (Others) and 3L

New plunger spring shim thickness

=

5.9

-

A

A

...

Measured plunger position

Plunger spring shim selection chart for 2L-T (Austria)

rnrn (in.)

Measured

Shim

Measured Shim

clearance

thickness

clearance thickness

More than

3.6

-

3.8

4.6 (0.181)

.5

(0.059)

(0.142

-

0.150) 2.5 (0.098)

4.1

-

4.2

Less than

(0.1 61

-

0.1 65) 2.0 (0.079) 3.2 (0.126) 3.0 (0.1 18)

Plunger spring shim selection chart for 2L-T (Others) and 3L

More than

4.3

-

4.5

1

5.3 (0.209)

7

0.5(0.020)

1

(0.169-0.1771

1

1.5 (0.059)

1

rnrn (in.)

HINT:

For

a

measurement between listed sizes, use the next

larger size. Ex. If thickness

is

1.1 mm (0.043 in.) by

calculation, use

a

1.2 mm (0.047 in.) shim.

Shim

thickness

4.8

-

4.9

Less than

(0.189

-

1.193)

1

.O (0.039) 3.9 (0.154)

Select

two

shims which have the same thickness.

Measured

clearance

Measured

clearance

2.0 (0.079)

Shim

thickness

Loading...

Loading...