ENGINE MECHANICAL

-

Cylinder Block

EM-47

Piston diameter:

2L-T STD mark

"1" 91.940

-

91.950

mm

(3.6197

-

3.6201

in.)

STD mark

"2" 91.950

-

91.960

mm

(3.6201

-

3.6205

in.)

STD mark

"3" 91.960

-

91.970

mm

(3.6205

-

3.6209

in.)

01s

0.50

92.440

-

92.470

mm

(3.6394

-

3.6405

in.)

Piston diameter:

3L

STD mark

"1" 95.940

-

95.950

mm

(3.7772

-

3.7776

in.)

STD mark

"2"

95.950

-

95.960

mm

(3.7776

-

3.7779

in.)

STD mark

"3" 95.960

-

95.970

mm

(3.7779

-

3.7783

in.)

01s

0.50

96.440

-

96.470

mm

(3.7968

-

3.7980

in.)

(b)

Measure the cylinder bore diameter in the thrust

directions. (See page EM-46)

(c)

Subtract the piston diameter measurement from the

cylinder bore diameter measurement.

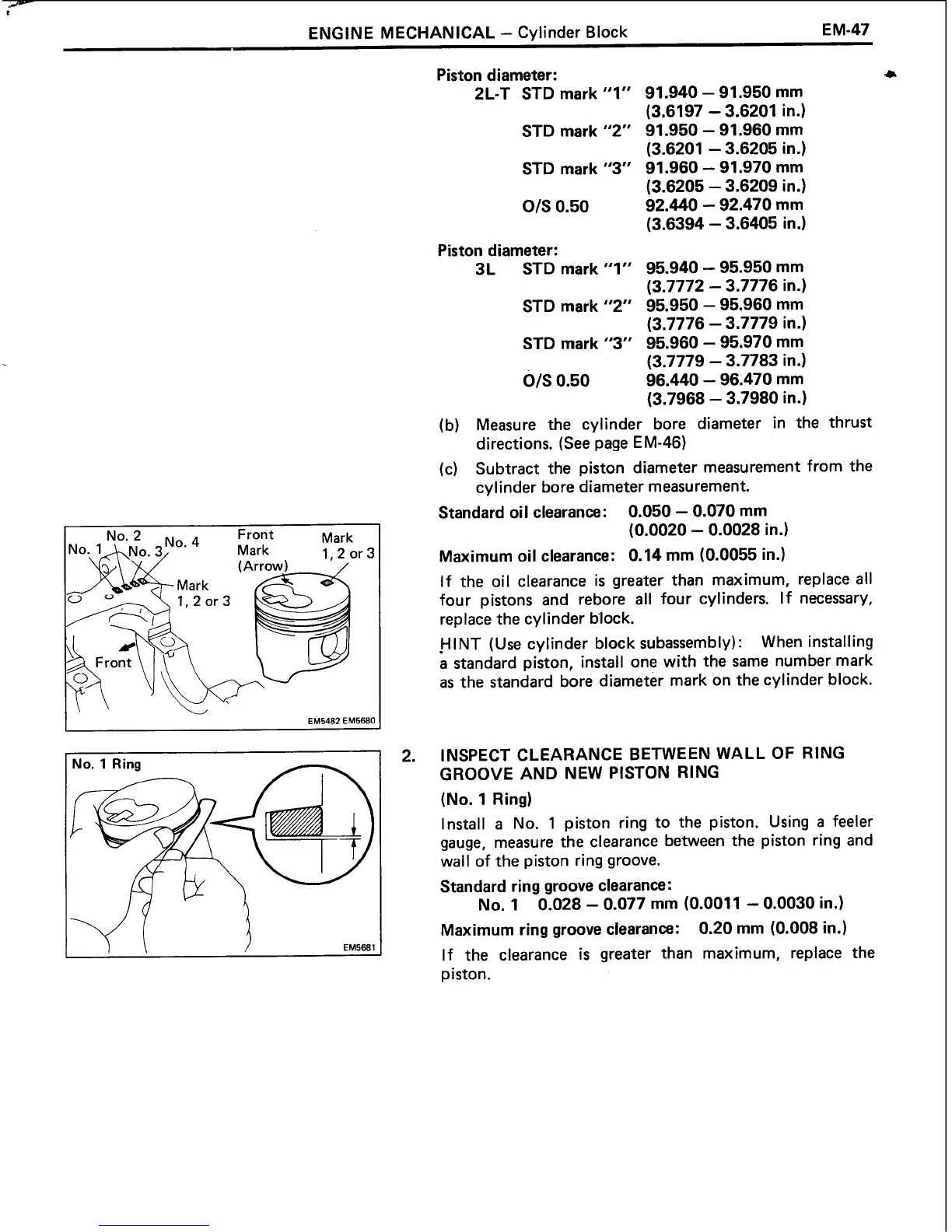

Front

Mark

1,201-3

EM5482

EM568C

Standard oil clearance:

0.050

-

0.070

mm

(0.0020

-

0.0028

in.)

Maximum oil clearance:

0.14

mm

(0.0055

in.)

If the oil clearance

is

greater than maximum, replace

all

four pistons and rebore

all

four cylinders. If necessary,

replace the cylinder block.

HINT (Use cylinder block subassembly):

When installing

a

standard piston, install one with the same number mark

as

the standard bore diameter mark on the cylinder block.

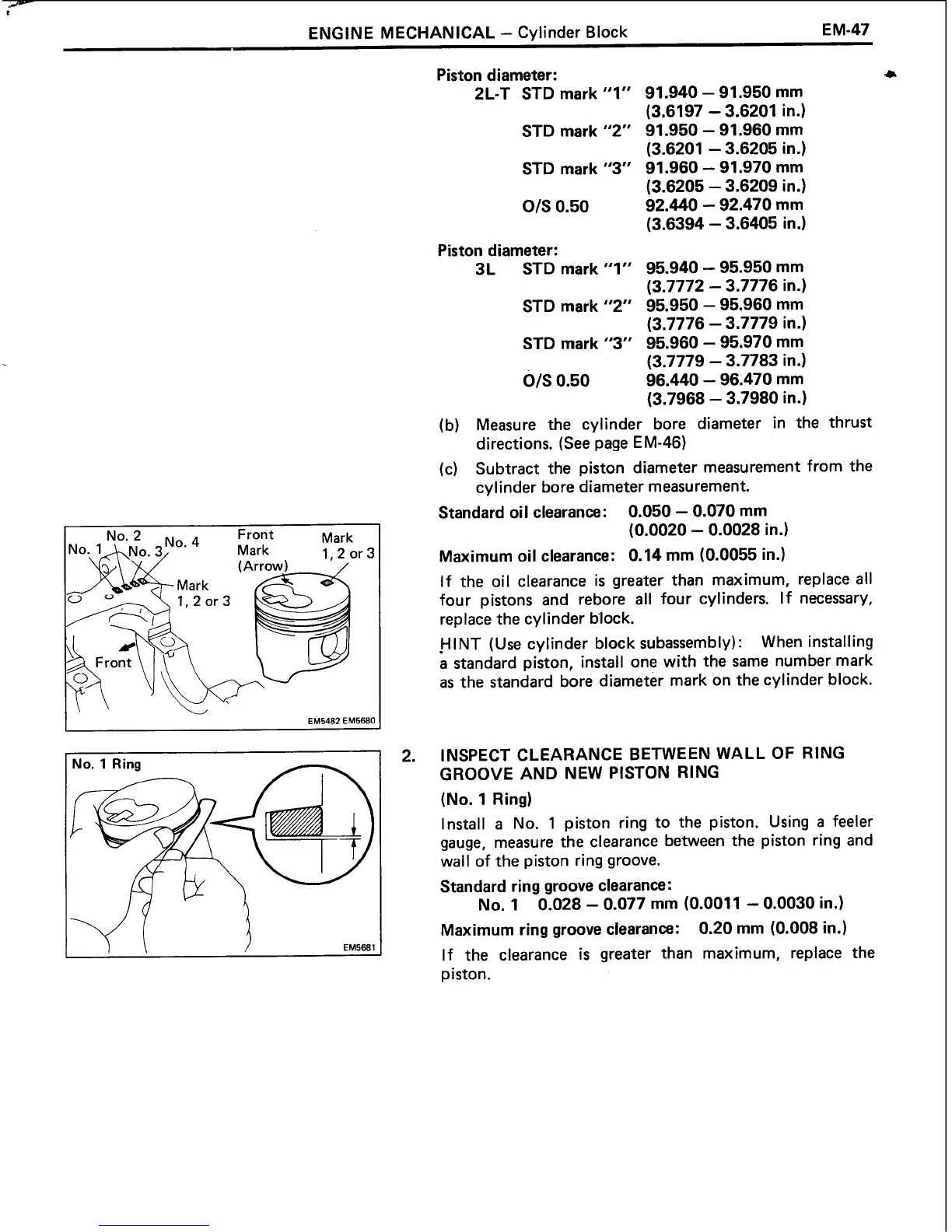

INSPECT CLEARANCE BETWEEN WALL OF RING

GROOVE AND NEW PISTON RING

(No.

1

Ring)

Install

a

No.

1

piston ring to the piston. Using

a

feeler

gauge, measure the clearance between the piston ring and

wall of the piston ring groove.

Standard ring groove clearance:

No.

1

0.028

-

0.077

mm

(0.001 1

-

0.0030

in.)

Maximum ring groove clearance:

0.20

mm

(0.008

in.)

If the clearance

is

greater than maximum, replace the

piston.

Loading...

Loading...