EM-48

ENGINE MECHANICAL

-

Cylinder Block

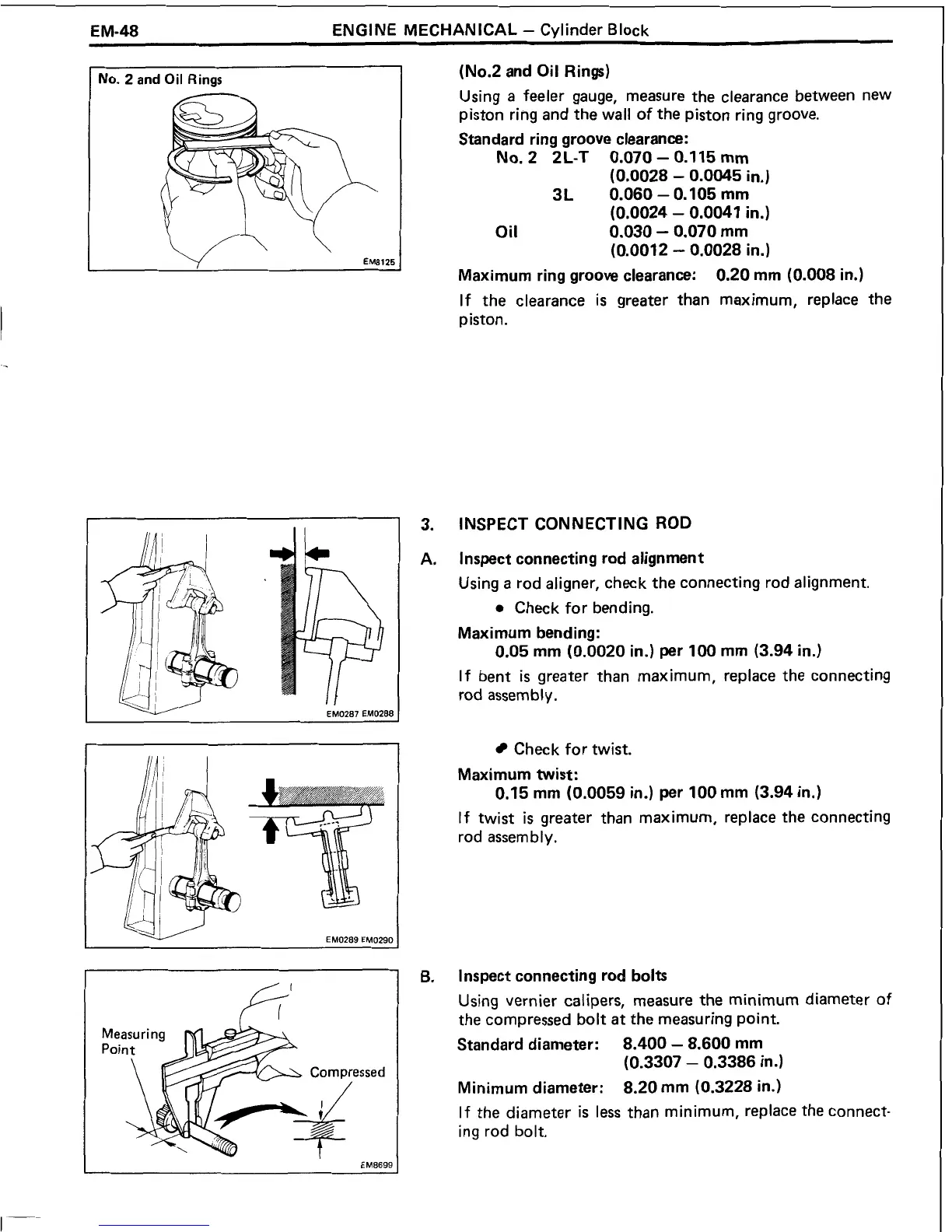

No.

2

and Oil Rings

essed

(No.2

and Oil Rings)

Using

a

feeler gauge, measure the clearance between new

piston ring and the wall of the piston ring groove.

Standard ring groove clearance:

No.

2 2L-T 0.070

-

0.1 15

mm

(0.0028

-

0.0045

in.)

3L 0.060

-

0.105

mm

(0.0024

-

0.0041

in.)

Oil

0.030

-

0.070

mm

(0.0012

-

0.0028

in.)

Maximum ring groove clearance:

0.20

mm

(0.008

in.)

If the clearance

is

greater than maximum, replace the

piston.

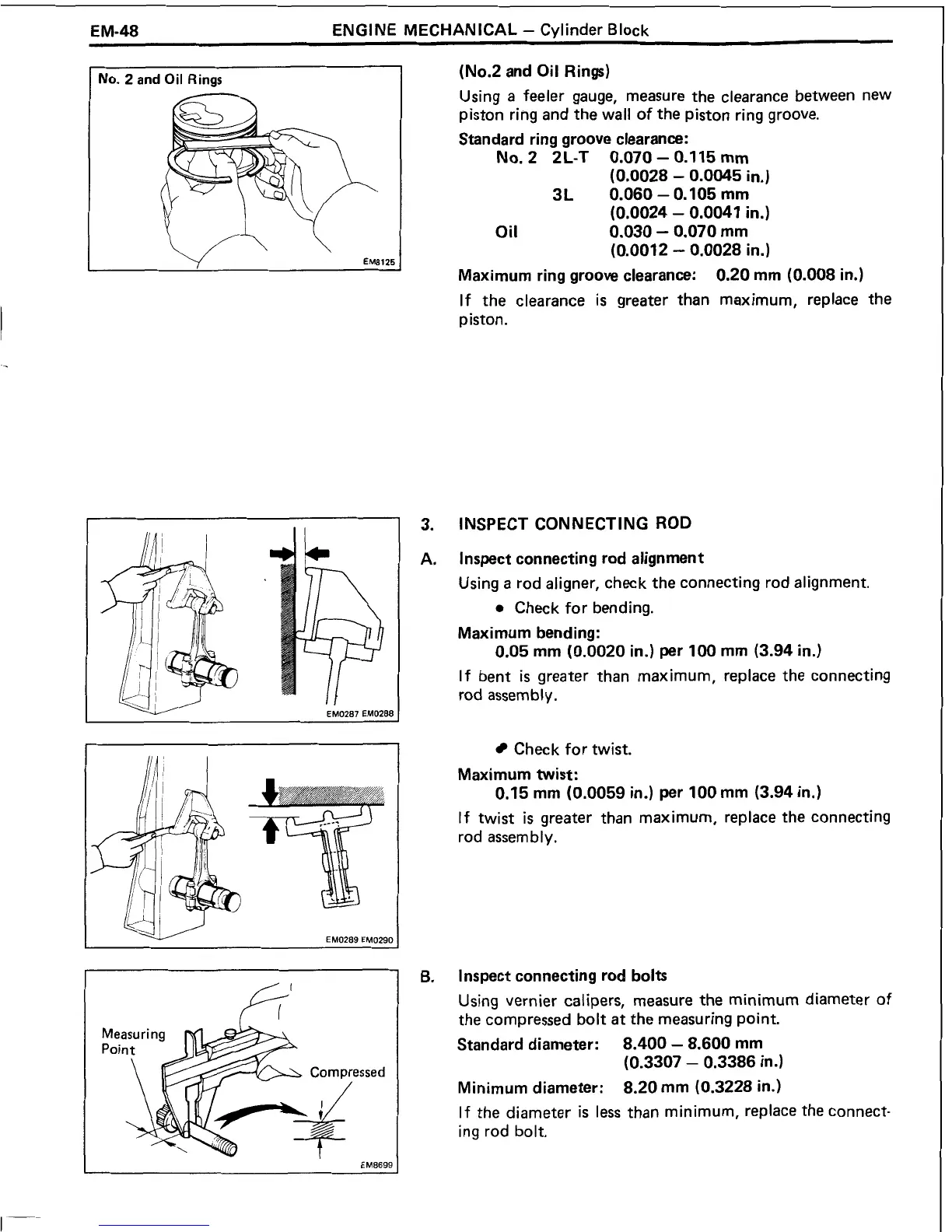

INSPECT CONNECTING ROD

Inspect connecting rod alignment

Using

a

rod aligner, check the connecting rod alignment.

0

Check for bending.

Maximum bending:

0.05

mm

(0.0020

in.) per

100

mm

(3.94

in.)

If bent

is

greater than maximum, replace the connecting

rod assembly.

Check for twist.

Maximum twist:

0.15

mm

(0.0059

in.) per

100

mm

(3.94

in.)

If twist

is

greater than maximum, replace the connecting

rod assembly.

l

nspect connecting rod bolts

Using vernier calipers, measure the minimum diameter of

the compressed bolt

at

the measuring point.

Standard diameter:

8.400

-

8.600

mm

(0.3307

-

0.3386

in.)

Minimum diameter:

8.20

mm

(0.3228

in.)

If the diameter

is

less than minimum, replace the connect-

ing rod bolt.

Loading...

Loading...