TURBOCHARGER

SYSTEM

-

Description TC-3

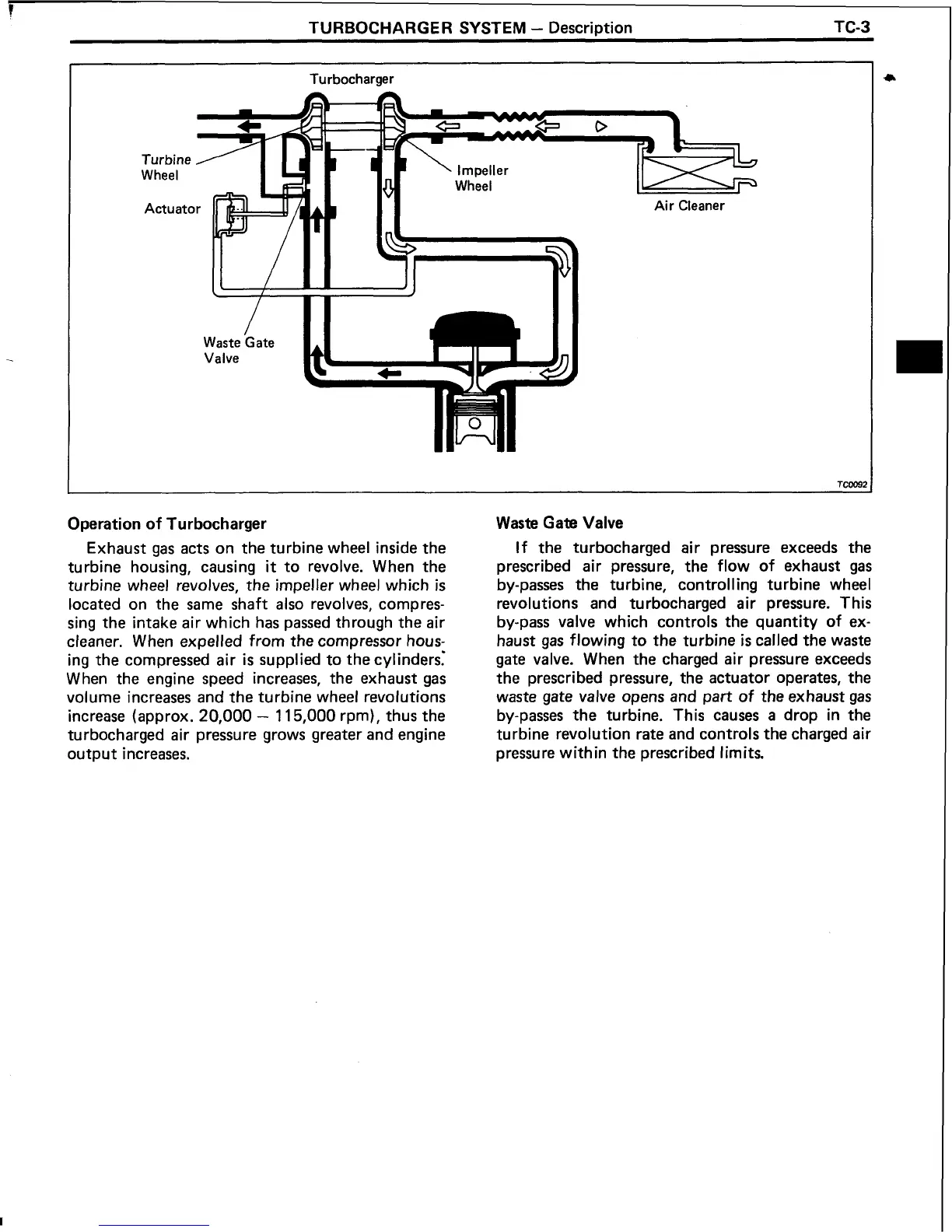

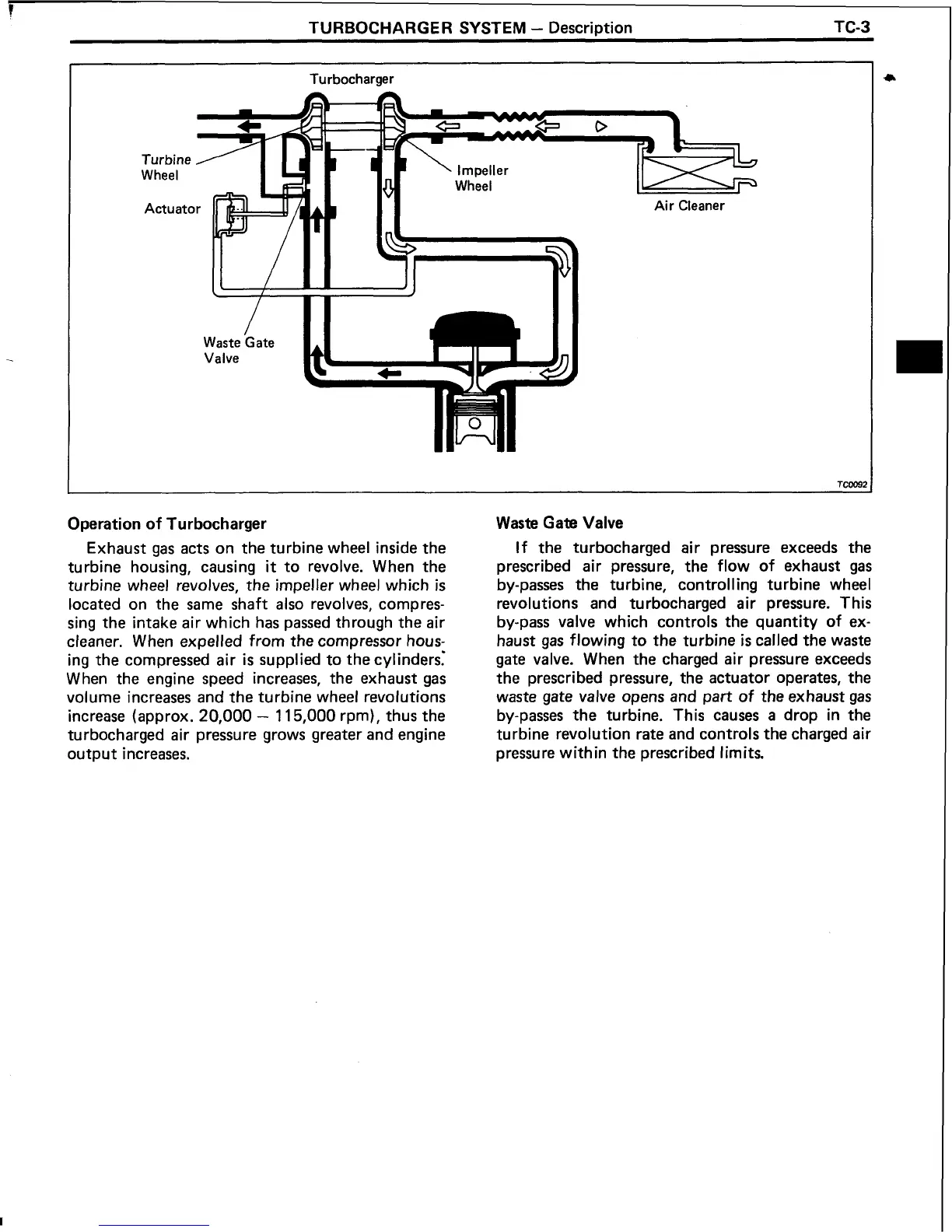

Turbocharger

Operation of Turbocharger

Waste Gate Valve

Exhaust gas acts on the turbine wheel inside the

turbine housing, causing

it

to revolve. When the

turbine wheel revolves, the impeller wheel which

is

located on the same shaft also revolves, compres-

sing the intake air which has passed through the air

cleaner. When expelled from the compressor hous-

ing the compressed air

is

supplied to the cylinders:

When the engine speed increases, the exhaust gas

volume increases and the turbine wheel revolutions

increase (approx. 20,000

-

1

15,000 rpm), thus the

turbocharged air pressure grows greater and engine

output increases.

If

the turbocharged air pressure exceeds the

prescribed air pressure, the flow of exhaust gas

by-passes the turbine, controlling turbine wheel

revolutions and turbocharged air pressure. This

by-pass valve which controls the quantity of ex-

haust gas flowing to the turbine

is

called the waste

gate valve. When the charged air pressure exceeds

the prescribed pressure, the actuator operates, the

waste gate valve opens and part of the exhaust gas

by-passes the turbine. This causes

a

drop in the

turbine revolution rate and controls the charged air

pressure within the prescribed limits.

Loading...

Loading...