FUEL SYSTEM/ENGINE MANAGEMENT 9

5.

Drain the engine oil as described in the lubrication

section.

6.

Remove the clutch cover.

7.

Release the sensor multiplug and detach the

sensor grommet from the crankcase.

8.

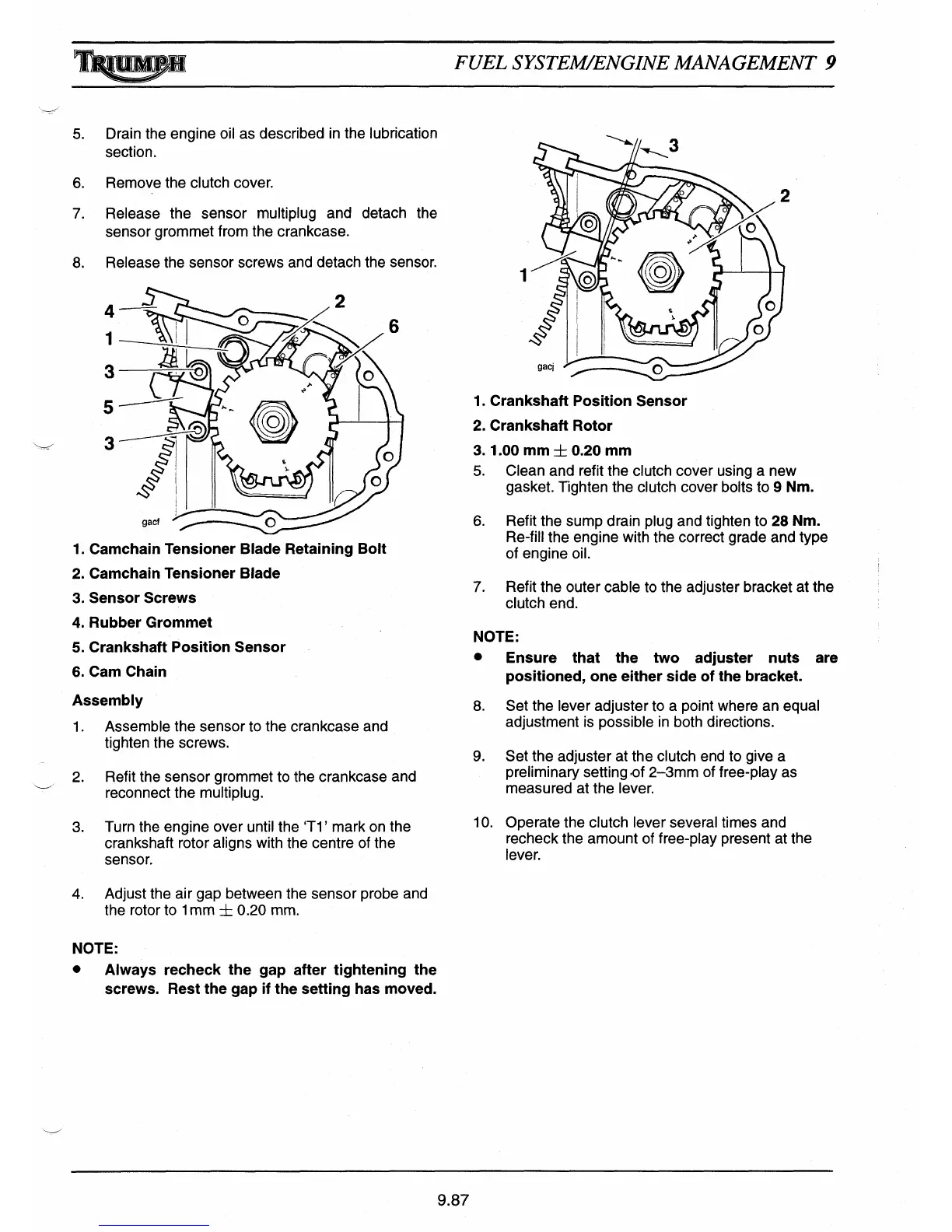

Release the sensor screws and detach the sensor.

4

1

3

5

3

gact

p

1.

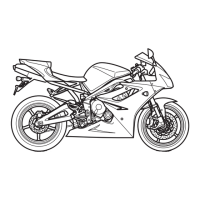

Camchain Tensioner Blade Retaining Bolt

2.

Camchain Tensioner Blade

3.

Sensor Screws

4.

Rubber Grommet

5.

Crankshaft Position Sensor

6.

Cam Chain

Assembly

1.

Assemble the sensor to the crankcase and

tighten the screws.

2.

Refit the sensor grommet to the crankcase and

reconnect the multiplug.

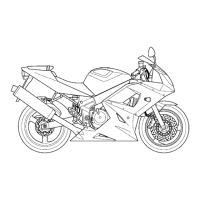

3.

Turn the engine over until the 'Ti' mark on the

crankshaft rotor aligns with the centre of the

sensor.

4.

Adjust the air gap between the sensor probe and

the rotor to 1 mm ± 0.20 mm.

NOTE:

•

Always recheck the gap after tightening the

screws. Rest the gap if the setting has moved.

1

1.

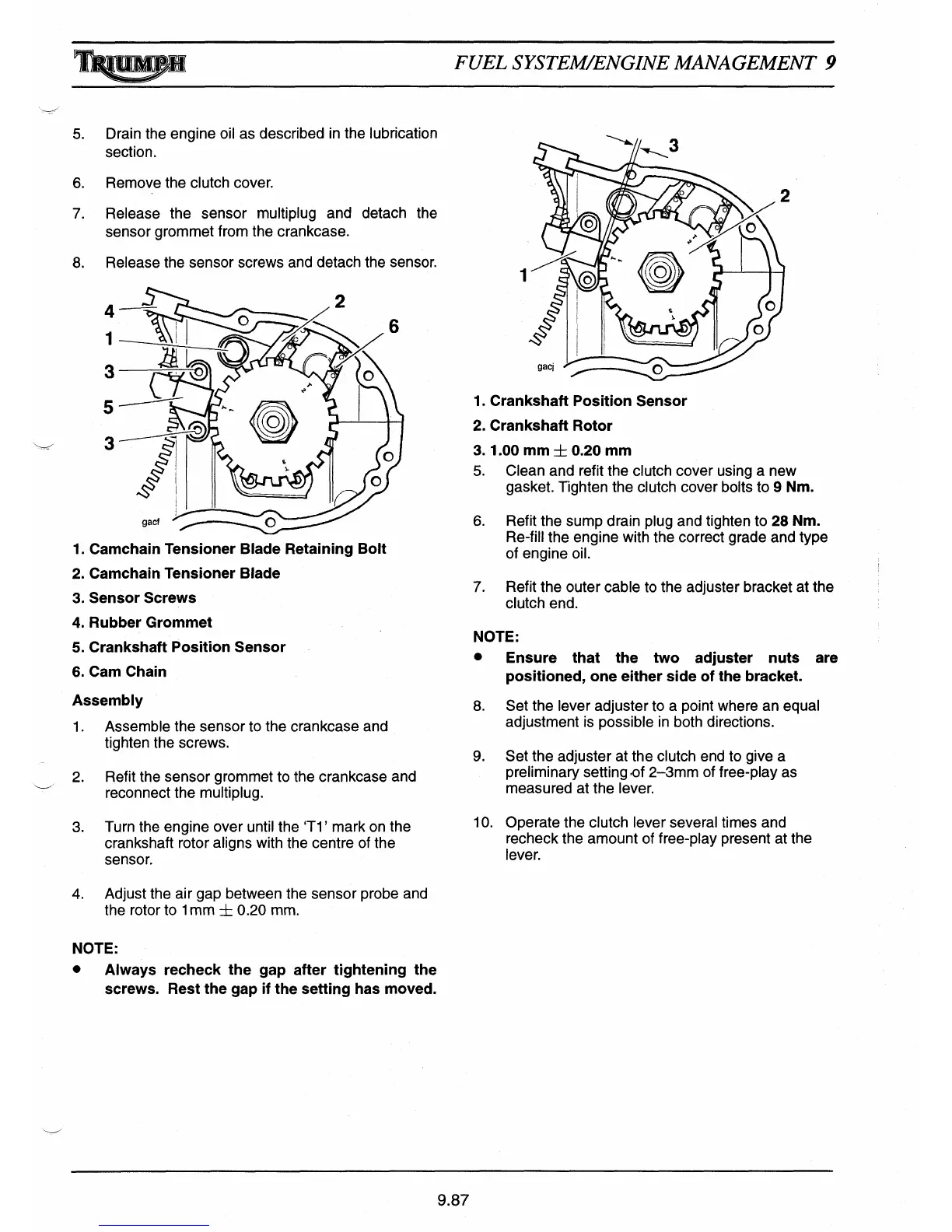

Crankshaft Position Sensor

2.

Crankshaft Rotor

3.

1.00 mm

+

0.20 mm

5.

Clean and refit the clutch cover using a new

gasket. Tighten the clutch cover bolts to

9 Nm.

6.

Refit the sump drain plug and tighten to

28 Nm.

Re-fill the engine with the correct grade and type

of engine oil.

7.

Refit the outer cable to the adjuster bracket at the

clutch end.

NOTE:

•

Ensure that the two adjuster nuts are

positioned, one either side of the bracket.

8.

Set the lever adjuster to a point where an equal

adjustment is possible in both directions.

9.

Set the adjuster at the clutch end to give a

preliminary setting .of 2-3mm of free-play as

measured at the lever.

10.

Operate the clutch lever several times and

recheck the amount of free-play present at the

lever.

9.87

Loading...

Loading...