13 BRAKING SYSTEM

TRnJMH

Installation

WARNING: Never use mineral based

grease in any part of the braking system

or in any area where contact with the braking

system is possible. Mineral based grease will

damage the hydraulic seals in the calipers and

master cylinders.

Damage caused by contact with mineral based

grease may reduce braking efficiency resulting in

an accident.

Fit new brake pads as an axle set or, if all the

pads are in a serviceable condition, clean the pad

grooves before refitting all pads in their original

positions.

WARNING: Do not apply more than a

minimum coating of grease to the pad

retaining pins. Excess grease may contaminate

the brake pads, hydraulic seals and discs causing

reduced braking efficiency and an accident.

2.

Lubricate the pad retaining pins using a minimum

amount of proprietary high temperature

'Copperslip' type grease.

3.

Fit the anti—rattle spring over the pads and push

down in the centre to allow the pad retaining pin

to slide across the top of the spring.

4.

Tighten the pad retaining pins to 25 Nm, and

secure with new split pins.

5.

Pump the brake lever to correctly position the

caliper pistons.

Observe the brake fluid handling warnings given

earlier in this section of the manual.

6.

Check the front brake fluid level and top up as

required with new DOT 4 fluid.

FRONT BRAKE CALIPER

Removal

CAUTION: To prevent body damage, do

•

not spill brake fluid onto any area of the

bodywork.

1.

Disconnect the brake hose at the caliper (two

hoses on right hand caliper), and place the free

end of the hose(s) in a suitable container to

collect brake fluid.

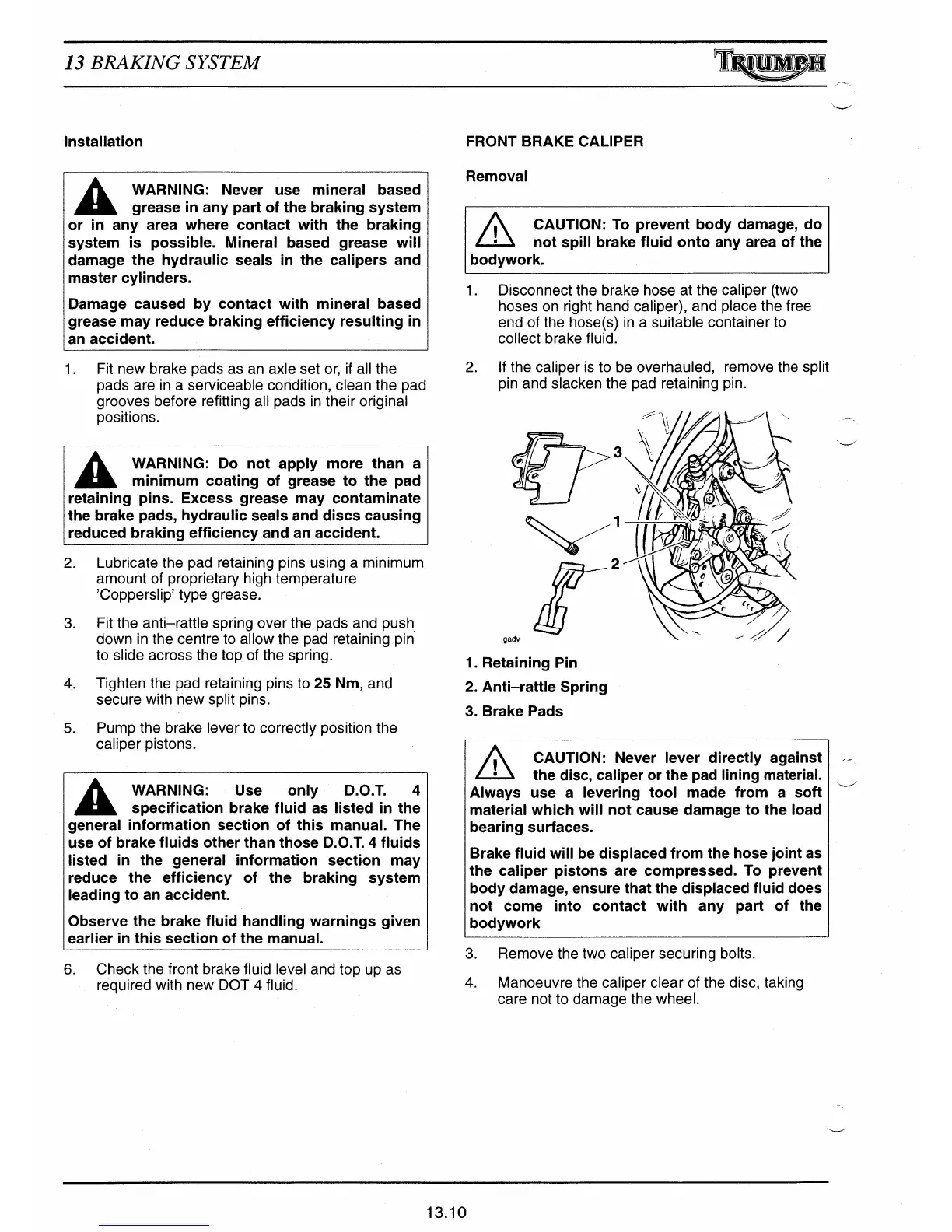

2.

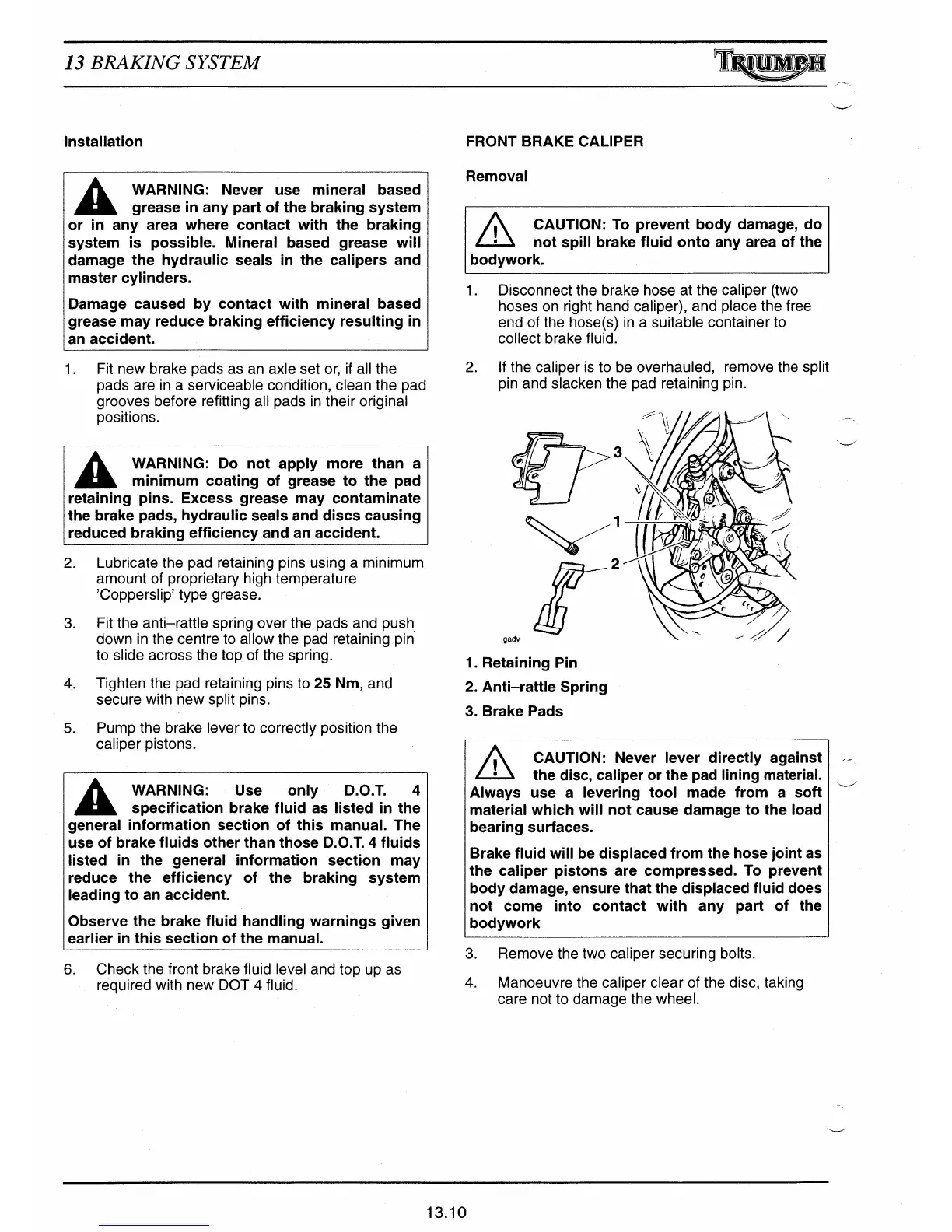

If the caliper is to be overhauled, remove the split

pin and slacken the pad retaining pin.

1.

Retaining Pin

2.

Anti—rattle Spring

3.

Brake Pads

CAUTION: Never lever directly against

•

the disc, caliper or the pad lining material.

Always use a levering tool made from a soft

material which will not cause damage to the load

bearing surfaces.

Brake fluid will be displaced from the hose joint as

the caliper pistons are compressed. To prevent

body damage, ensure that the displaced fluid does

not come into contact with any part of the

bodywork

3.

Remove the two caliper securing bolts.

4.

Manoeuvre the caliper clear of the disc, taking

care not to damage the wheel.

3

P

2

gadv

13.10

Loading...

Loading...