gack

5 BALANCERS

Tke2pff

Examination

Before assembly, check the following items:

•

Shaft bearings for overheating (blue coloured

areas), loose or missing rollers etc.

•

Shaft bearing areas and sleeves for overheating

(blue coloured areas), grooving, scoring etc.

•

Drive gear and backlash eliminator gears for tooth

damage, overheating etc.

•

Belleville washer for distortion.

Assembly

NOTE:

•

Prior to beginning the assembly process,

locate the shaft to the vice in the same way as

for disassembly.

1.

Locate the right hand bearing and sleeve to the

shaft.

2.

Apply `Loctite 270' to the threads of a new

large-head capscrew. Fit and tighten the capscrew

to

40 Nm.

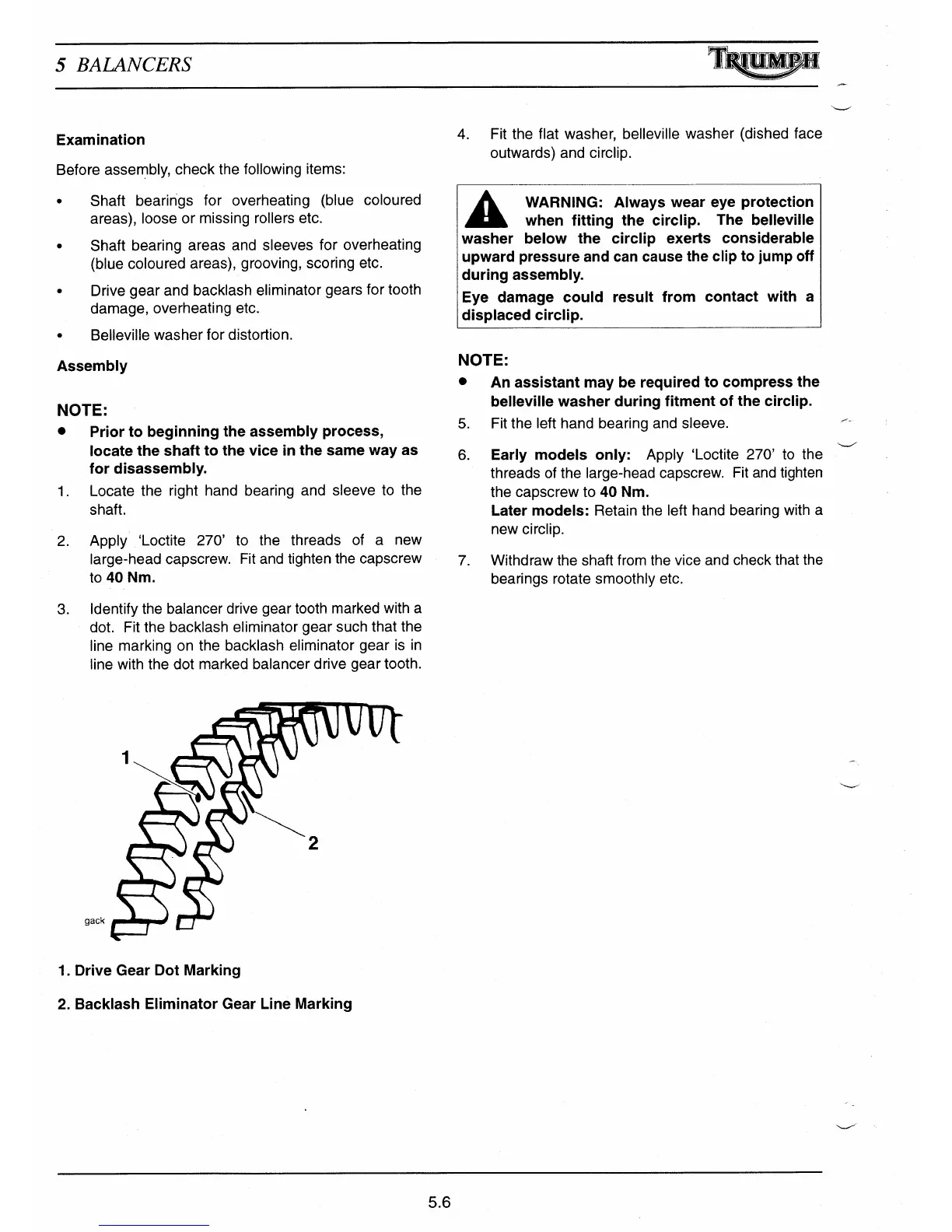

3.

Identify the balancer drive gear tooth marked with a

dot. Fit the backlash eliminator gear such that the

li

ne marking on the backlash eliminator gear is in

li

ne with the dot marked balancer drive gear tooth.

4.

Fit the flat washer, belleville washer (dished face

outwards) and circlip.

WARNING: Always wear eye protection

when fitting the circlip. The belleville

washer below the circlip exerts considerable

upward pressure and can cause the clip to jump off

during assembly.

Eye damage could result from contact with a

displaced circlip.

NOTE:

•

An assistant may be required to compress the

belleville washer during fitment of the circlip.

5.

Fit the left hand bearing and sleeve.

6.

Early models only:

Apply `Loctite 270' to the

threads of the large-head capscrew. Fit and tighten

the capscrew to

40 Nm.

Later models:

Retain the left hand bearing with a

new circlip.

7.

Withdraw the shaft from the vice and check that the

bearings rotate smoothly etc.

1.

Drive Gear Dot Marking

2.

Backlash Eliminator Gear Line Marking

5.6