Engine Installation

1.

Position the engine beneath the frame.

2.

Raise the engine and loop the drive chain over

the output sprocket.

3.

Align the engine to the frame and refit the engine

mounting bolts to support the engine.

4.

Slacken the inner lock/adjuster rings for the

swinging arm.

5.

Remove the support from beneath the engine.

6.

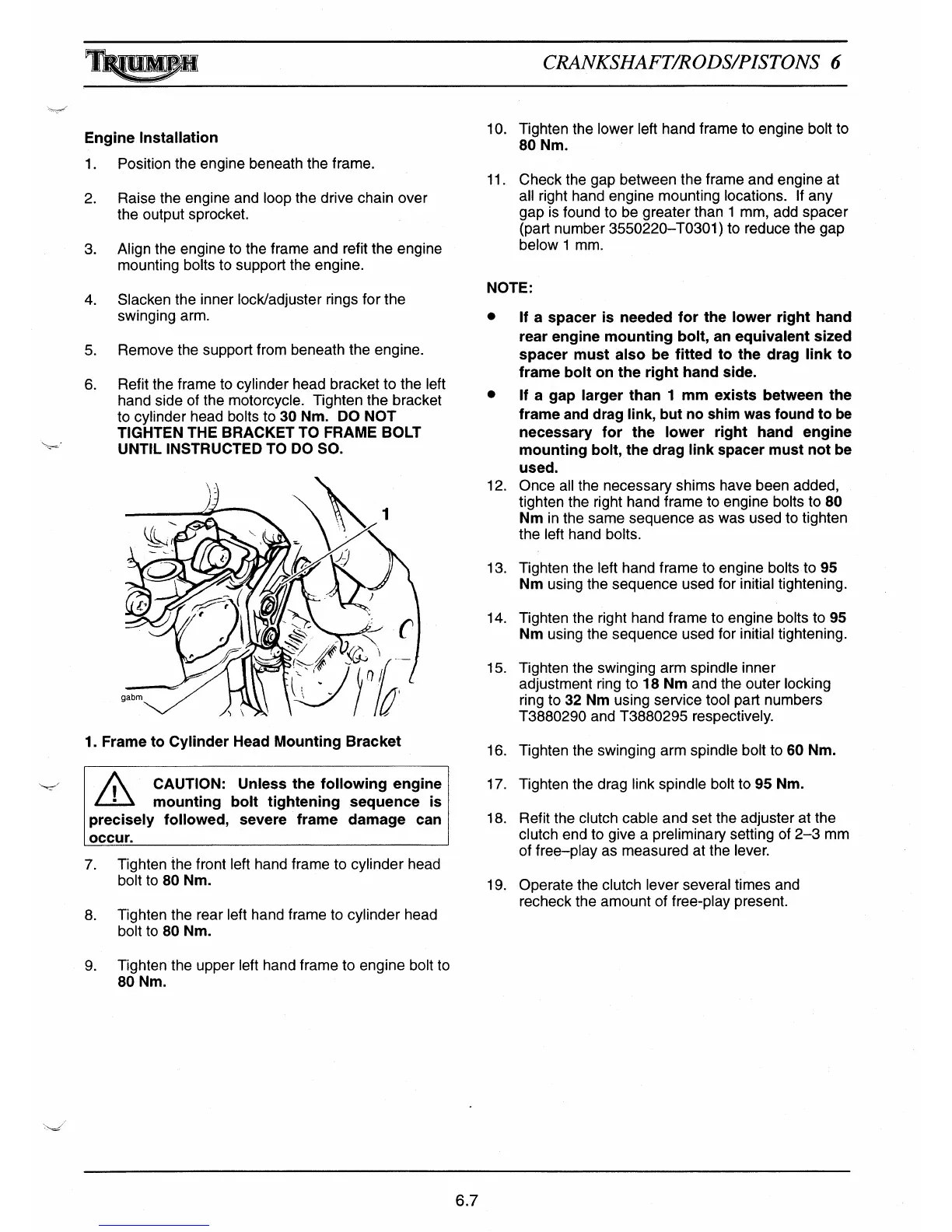

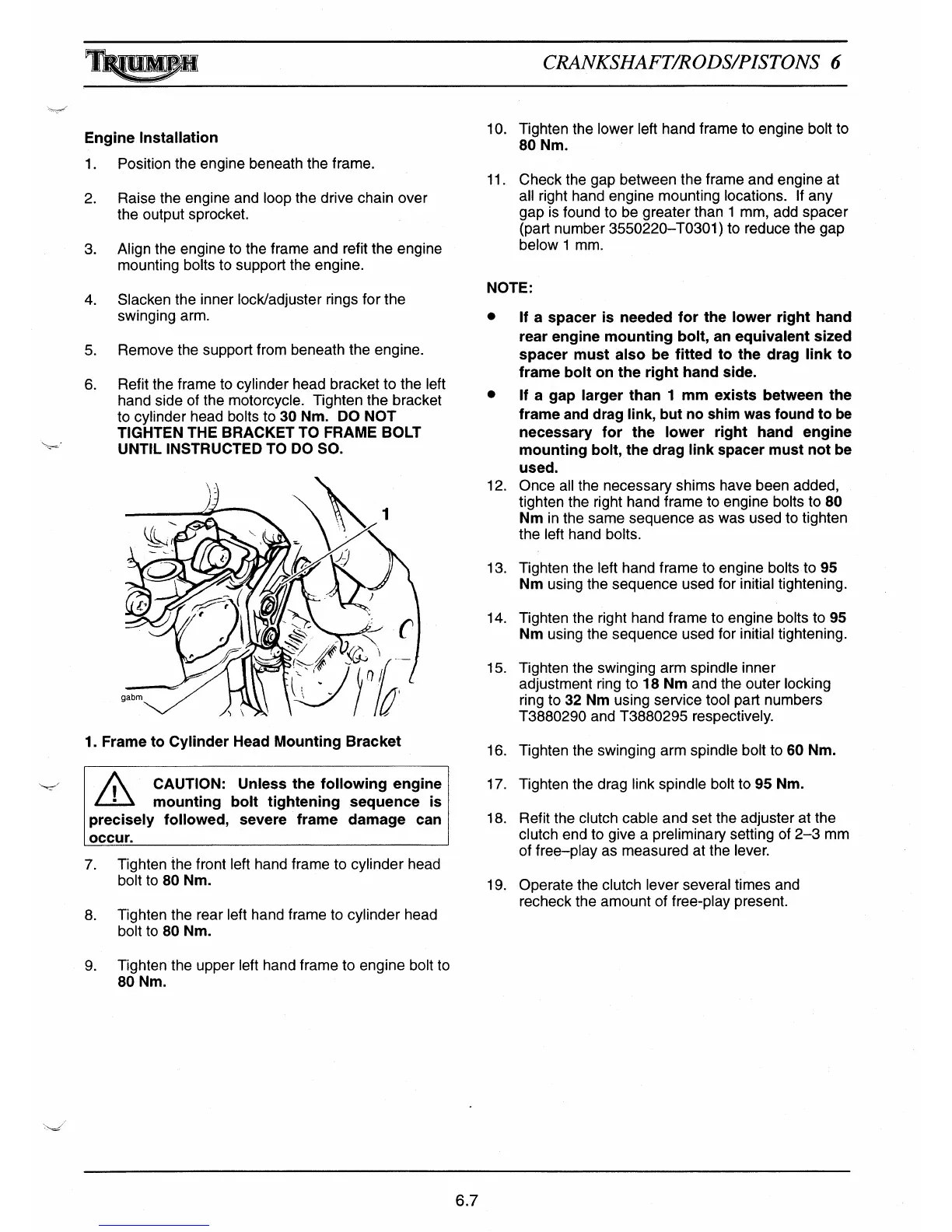

Refit the frame to cylinder head bracket to the left

hand side of the motorcycle. Tighten the bracket

to cylinder head bolts to 30 Nm. DO NOT

TIGHTEN THE BRACKET TO FRAME BOLT

UNTIL INSTRUCTED TO DO SO.

1. Frame to Cylinder Head Mounting Bracket

'

/\

^

CAUTION: Unless the following engine

•

mounting bolt tightening sequence is

precisely followed, severe frame damage can

occur.

7.

Tighten the front left hand frame to cylinder head

bolt to 80 Nm.

8.

Tighten the rear left hand frame to cylinder head

bolt to 80 Nm.

9.

Tighten the upper left hand frame to engine bolt to

80 Nm.

ifl

MPI

CRANKSHAFT/RODS/PISTONS 6

10. Tighten the lower left hand frame to engine bolt to

80 Nm.

11. Check the gap between the frame and engine at

all right hand engine mounting locations. If any

gap is found to be greater than 1 mm, add spacer

(part number 3550220—T0301) to reduce the gap

below 1 mm.

NOTE:

•

If a spacer is needed for the lower right hand

rear engine mounting bolt, an equivalent sized

spacer must also be fitted to the drag link to

frame bolt on the right hand side.

If a gap larger than 1 mm exists between the

frame and drag link, but no shim was found to be

necessary for the lower right hand engine

mounting bolt, the drag link spacer must not be

used.

12.

Once all the necessa

ry

shims have been added,

tighten the right hand frame to engine bolts to 80

Nm in the same sequence as was used to tighten

the left hand bolts.

13. Tighten the left hand frame to engine bolts to 95

Nm using the sequence used for initial tightening.

14. Tighten the right hand frame to engine bolts to 95

Nm using the sequence used for initial tightening.

15. Tighten the swinging arm spindle inner

adjustment ring to 18 Nm and the outer locking

ring to 32 Nm using service tool part numbers

T3880290 and T3880295 respectively.

16.

Tighten the swinging arm spindle bolt to 60 Nm.

17.

Tighten the drag link spindle bolt to 95 Nm.

18.

Refit the clutch cable and set the adjuster at the

clutch end to give a preliminary setting of 2-3 mm

of free—play as measured at the lever.

19.

Operate the clutch lever several times and

recheck the amount of free-play present.

6.7

Loading...

Loading...