6 CRANKSHAFT/RODS/PISTONS

TiUJMPU

CRANKSHAFT MAIN BEARING/JOURNAL WEAR

Main Bearing Selection Chart (all dimensions in mm's)

Shell Colour

White

Red

Red

Blue

Blue

Green

Crankcase Bore

41.126

41.118

41.126

41.118

41.135

41.127

41.135

41.127

41.144

41.136

41.144

41.136

Journal Dia'

37.976

37.969

37.968

37.960

37.976

37.969

37.968

37.960

37.976

37.969

37.968

37.960

Running

Clearance

All types

0.044 - 0.020

Minor differences in crankshaft dimensions are

crankshaft cannot be reground and no oversize

compensated for by using selective bearings. For further

bearings are available.

information on bearing part number to colour

Select bearings as follows:

cross-references, see the latest parts microfiche.

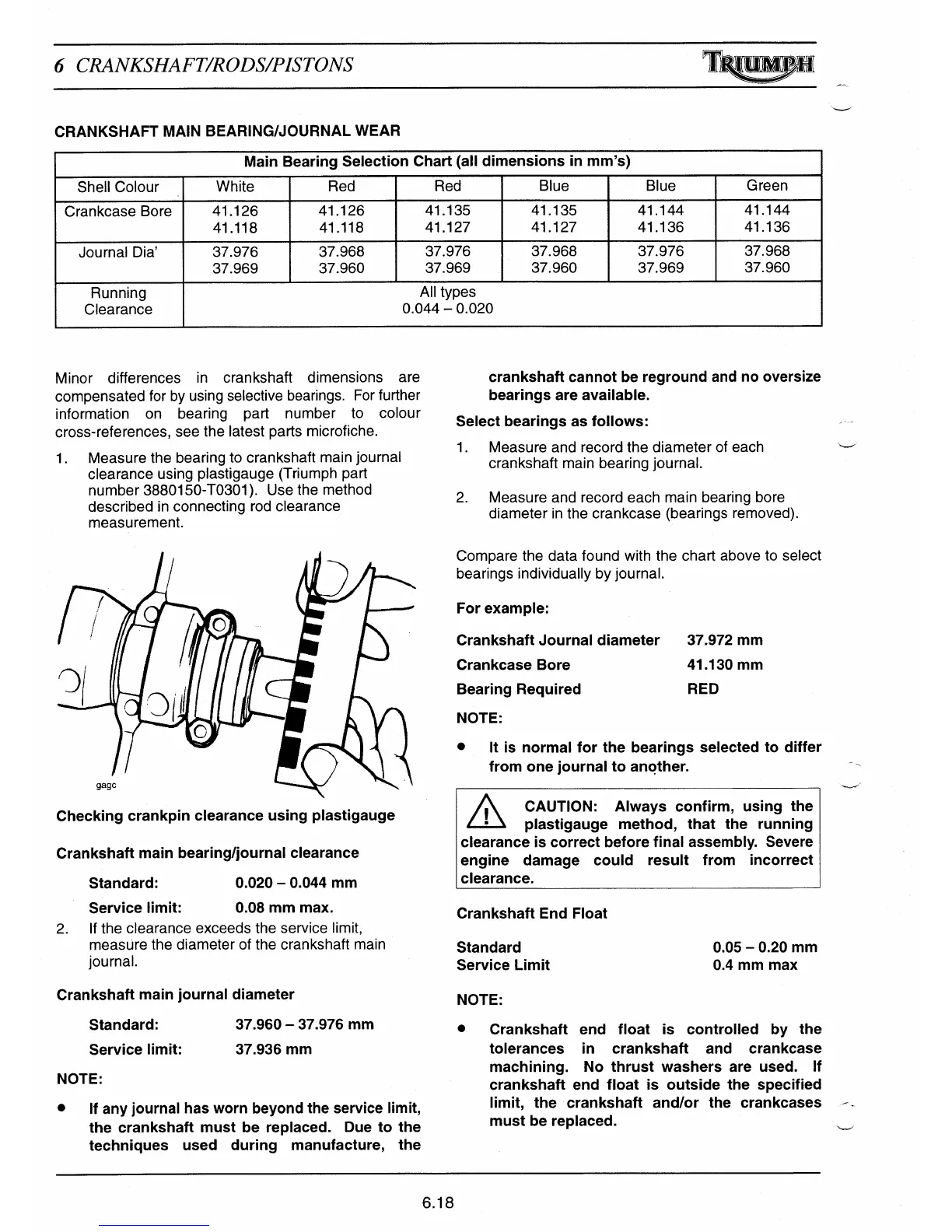

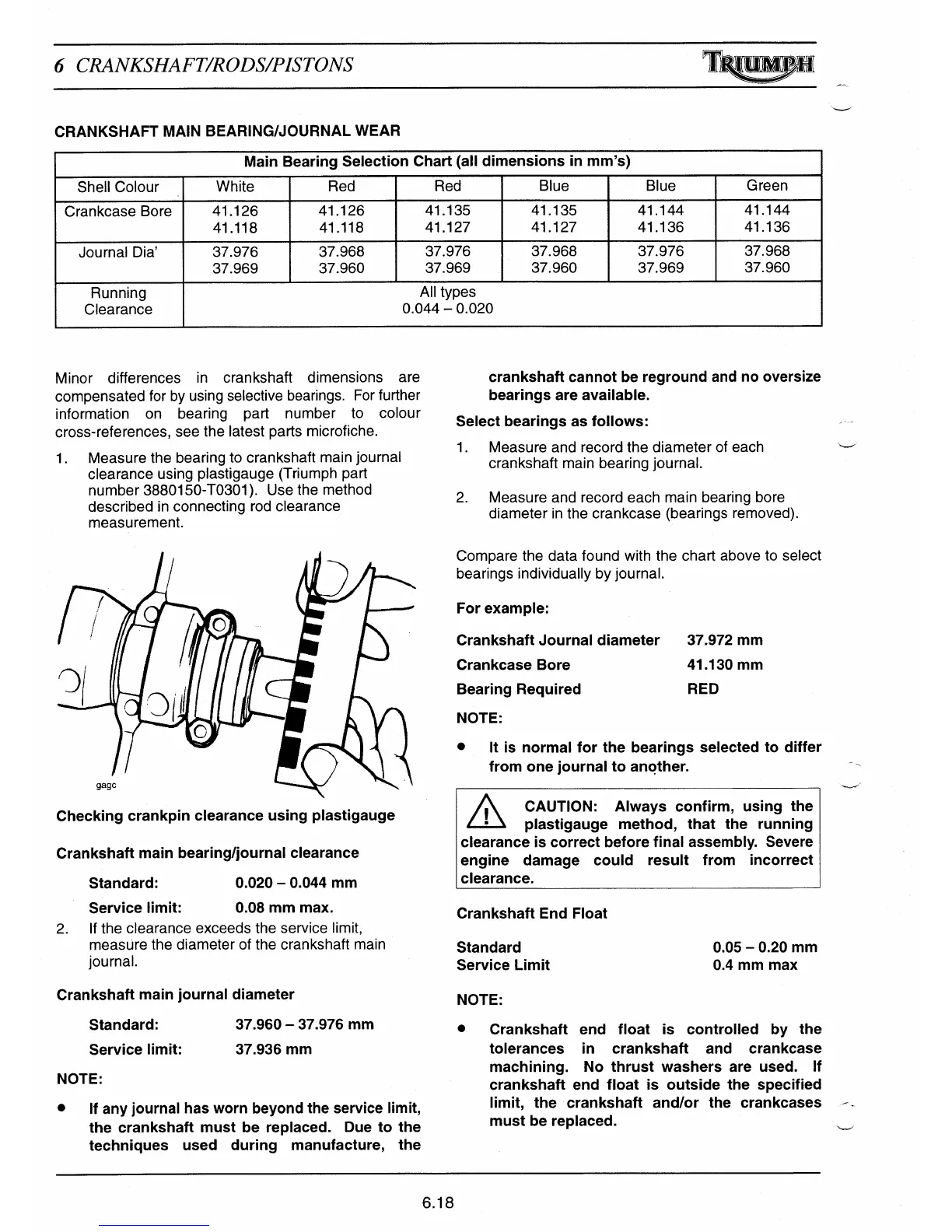

1.

Measure the bearing to crankshaft main journal

clearance using plastigauge (Triumph part

number 3880150-T0301). Use the method

described in connecting rod clearance

measurement.

Checking crankpin clearance using plastigauge

Crankshaft main bearing/journal clearance

Standard:

0.020 - 0.044 mm

Service limit:

0.08 mm max.

2.

If the clearance exceeds the service limit,

measure the diameter of the crankshaft main

journal.

Crankshaft main journal diameter

Standard:

37.960 - 37.976 mm

Service limit:

37.936 mm

NOTE:

•

If any journal has worn beyond the service limit,

the crankshaft must be replaced. Due to the

techniques used during manufacture, the

1. Measure and record the diameter of each

crankshaft main bearing journal.

2. Measure and record each main bearing bore

diameter in the crankcase (bearings removed).

Compare the data found with the chart above to select

bearings individually by journal.

For example:

Crankshaft Journal diameter

37.972 mm

Crankcase Bore

41.130 mm

Bearing Required

RED

NOTE:

•

It is normal for the bearings selected to differ

from one journal to another.

CAUTION: Always confirm, using the

•

plastigauge method, that the running

clearance is correct before final assembly. Severe

engine damage could result from incorrect

clearance.

Crankshaft End Float

Standard

0.05 - 0.20 mm

Service Limit

0.4 mm max

NOTE:

•

Crankshaft end float is controlled by the

tolerances in crankshaft and crankcase

machining. No thrust washers are used. If

crankshaft end float is outside the specified

li

mit, the crankshaft and/or the crankcases

must be replaced.

6.18

Loading...

Loading...