CYLINDER HEAD & CAMSHAFT 3

O4Q1

2

gaaa

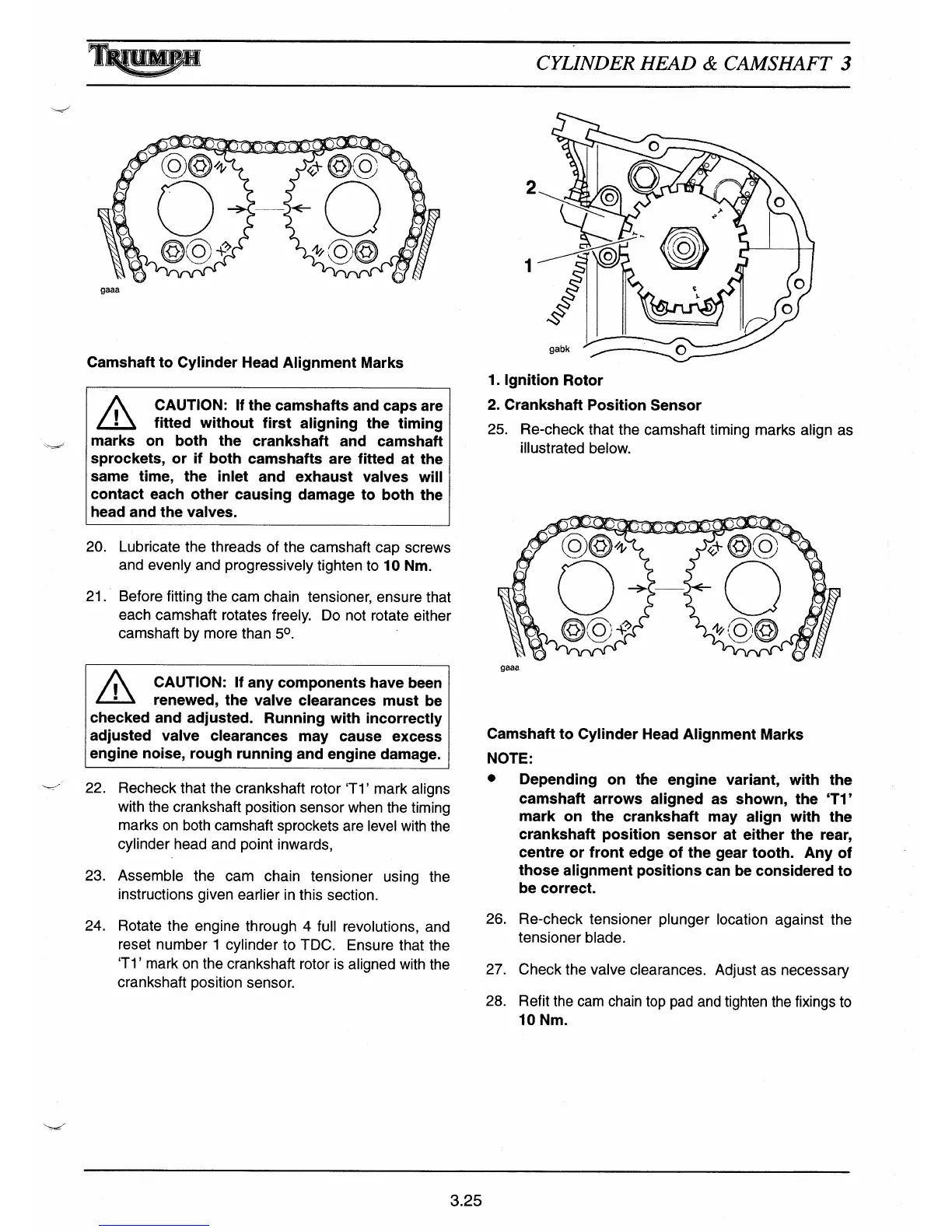

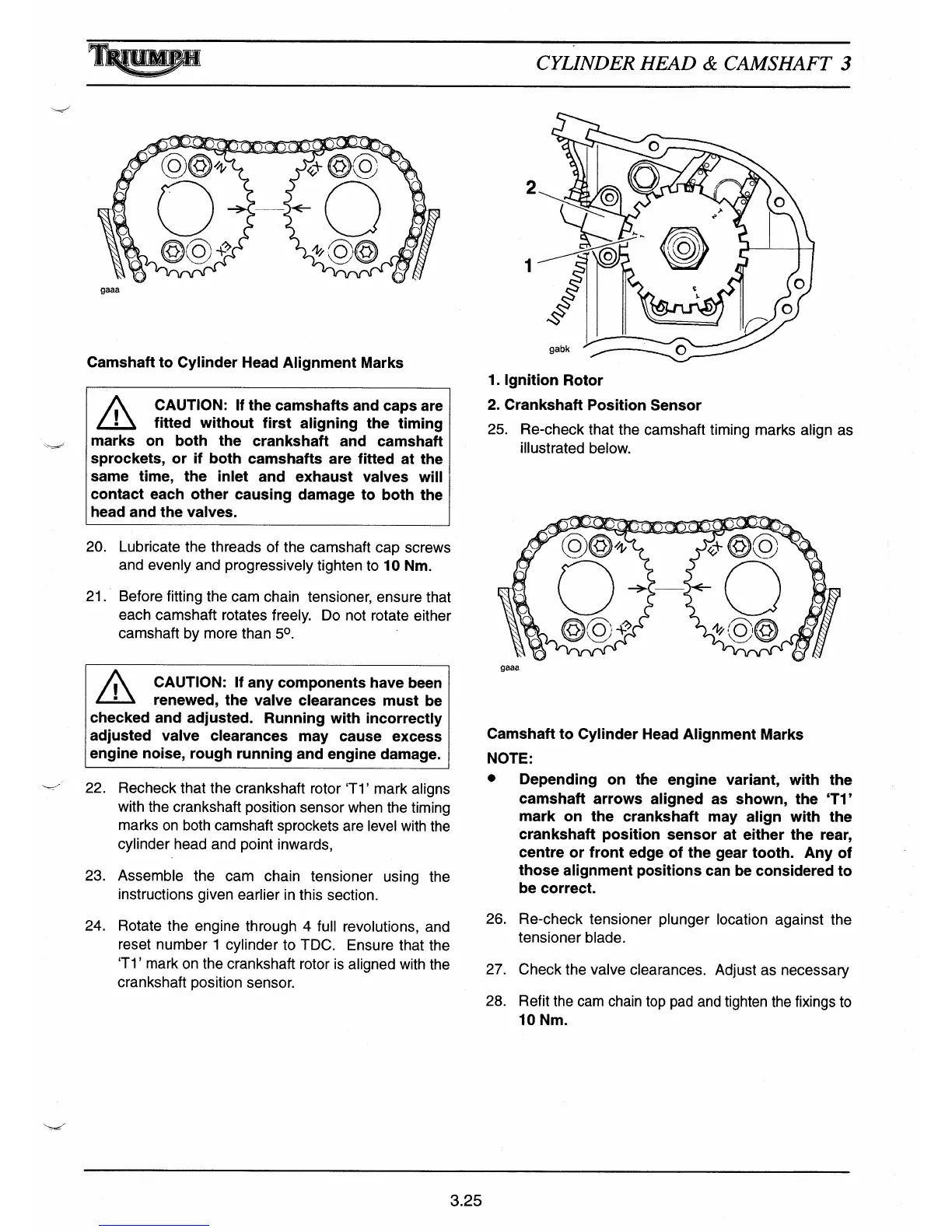

Camsha

ft

to Cylinder Head Alignment Marks

A

CAUTION: If the camshafts and caps are

fi

tt

ed without first aligning the timing

marks on both the crankshaft and camshaft

sprockets, or if both camshafts are fi

tt

ed at the

same time, the inlet and exhaust valves will

contact each other causing damage to both the

head and the valves.

20.

Lubricate the threads of the camshaft cap screws

and evenly and progressively tighten to 10 Nm.

21.

Before fitting the cam chain tensioner, ensure that

each camshaft rotates freely. Do not rotate either

camshaft by more than 5°.

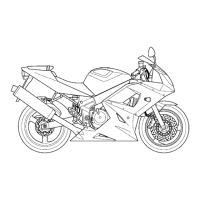

1.

Ignition Rotor

2.

Crankshaft Position Sensor

25. Re-check that the camshaft timing marks align as

ill

ustrated below.

o4Q

gaaa

^

CAUTION: If any components have been

•

renewed, the valve clearances must be

checked and adjusted. Running with incorrectly

adjusted valve clearances may cause excess

engine noise, rough running and engine damage.

22.

Recheck that the crankshaft rotor

'Ti'

mark aligns

with the crankshaft position sensor when the timing

marks on both camshaft sprockets are level with the

cylinder head and point inwards,

23.

Assemble the cam chain tensioner using the

instructions given earlier in this section.

24.

Rotate the engine through 4 full revolutions, and

reset number 1 cylinder to TDC. Ensure that the

'Ti'

mark on the crankshaft rotor is aligned with the

crankshaft position sensor.

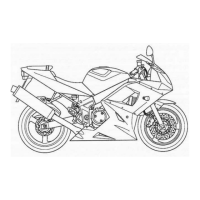

Camshaft to Cylinder Head Alignment Marks

NOTE:

•

Depending on the engine variant, with the

camshaft arrows aligned as shown, the

'Ti'

mark on the crankshaft may align with the

crankshaft position sensor at either the rear,

centre or front edge of the gear tooth. Any of

those alignment positions can be considered to

be correct.

26.

Re-check tensioner plunger location against the

tensioner blade.

27.

Check the valve clearances. Adjust as necessa

ry

28.

Refit the cam chain top pad and tighten the fixings to

10 Nm.

3.25

Loading...

Loading...