6 CRANKSHAFT/RODS/PISTONS

T

MPH

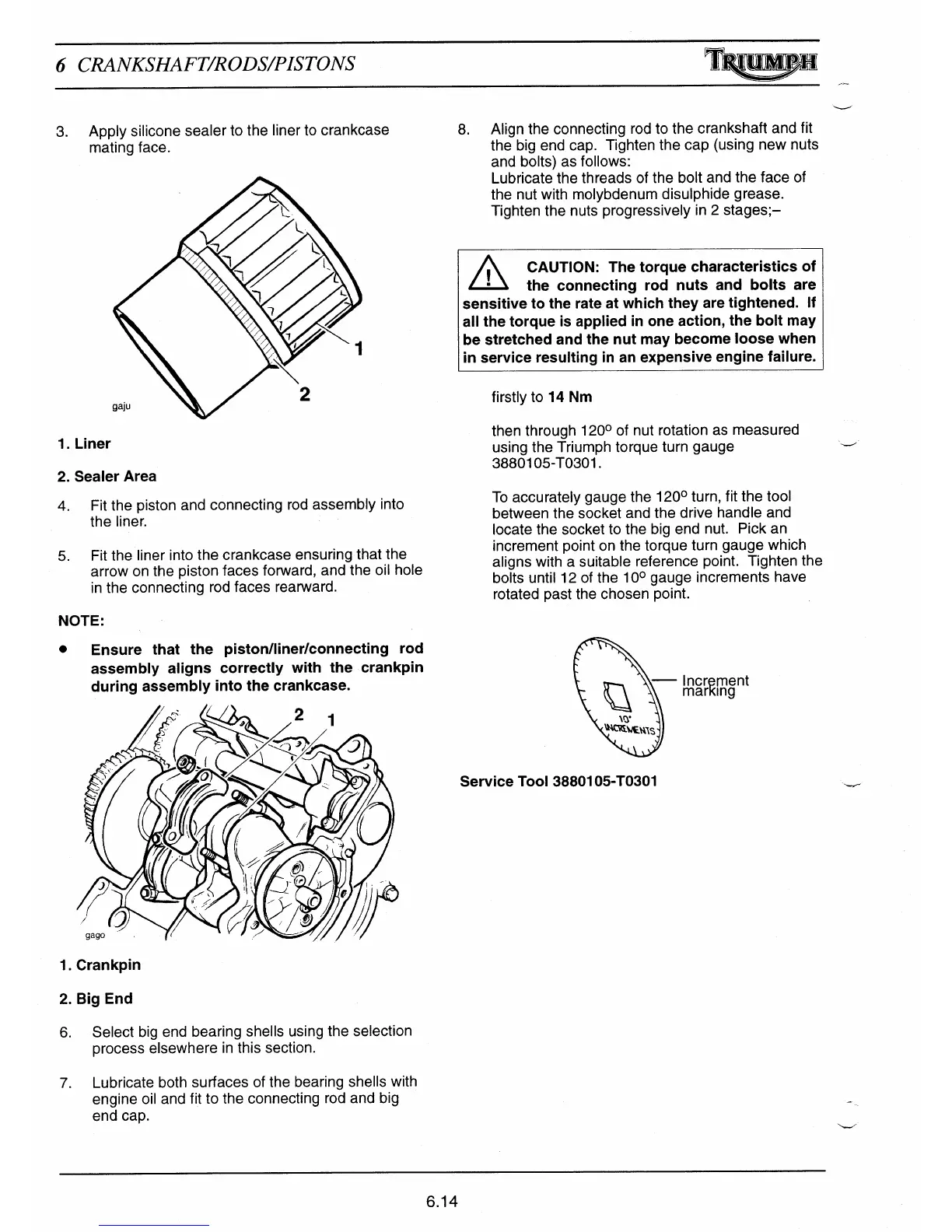

3.

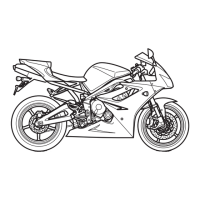

Apply silicone sealer to the liner to crankcase

mating face.

1.

Liner

2.

Sealer Area

4.

Fit the piston and connecting rod assembly into

the liner.

5.

Fit the liner into the crankcase ensuring that the

arrow on the piston faces forward, and the oil hole

in the connecting rod faces rearward.

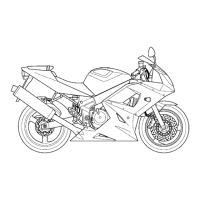

NOTE:

•

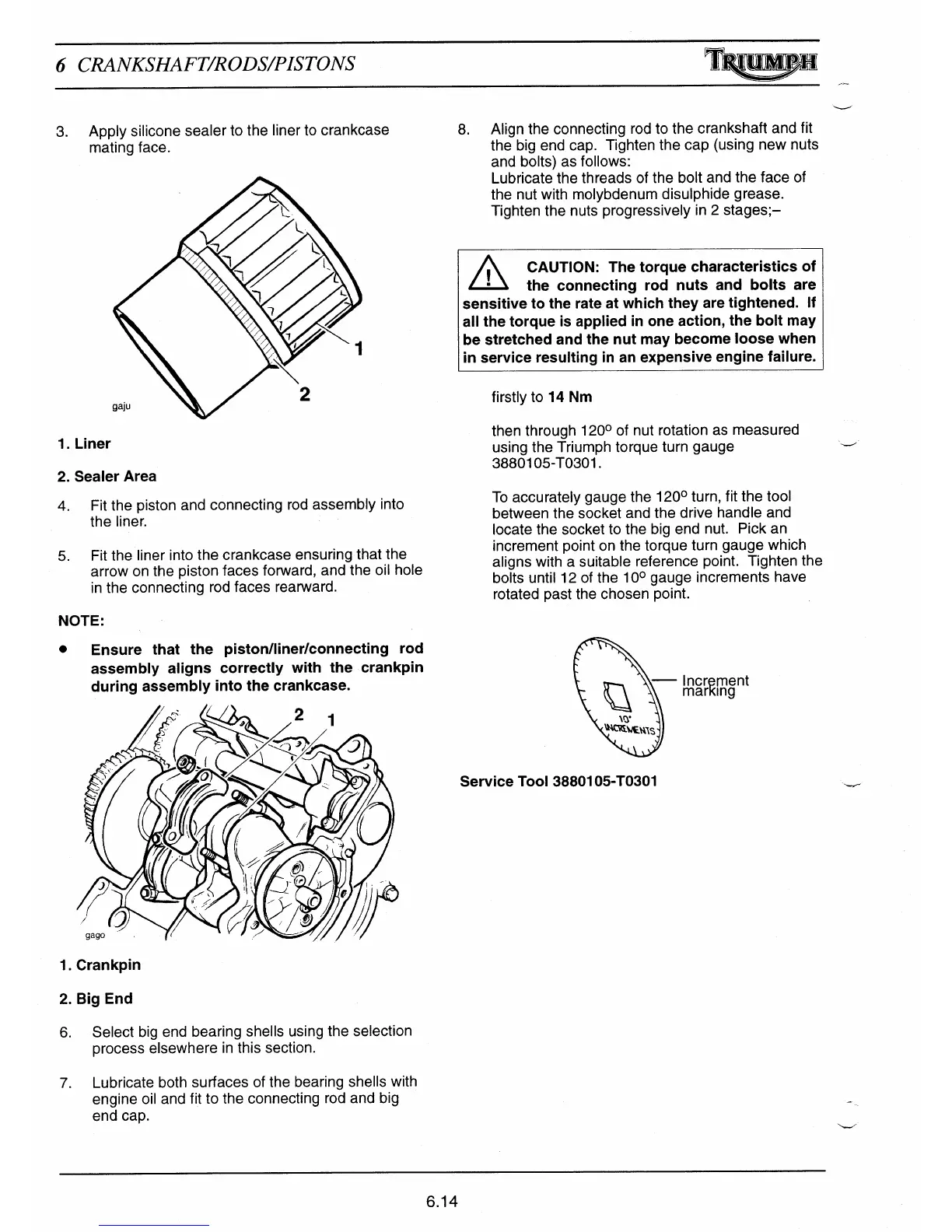

Ensure that the piston/liner/connecting rod

assembly aligns correctly with the crankpin

during assembly into the crankcase.

1.

Crankpin

2.

Big End

6.

Select big end bearing shells using the selection

process elsewhere in this section.

7.

Lubricate both surfaces of the bearing shells with

engine oil and fit to the connecting rod and big

end cap.

8.

Align the connecting rod to the crankshaft and fit

the big end cap. Tighten the cap (using new nuts

and bolts) as follows:

Lubricate the threads of the bolt and the face of

the nut with molybdenum disulphide grease.

Tighten the nuts progressively in 2 stages;—

CAUTION: The torque characteristics of

•

the connecting rod nuts and bolts are

sensitive to the rate at which they are tightened. If

all the torque is applied in one action, the bolt may

be stretched and the nut may become loose when

in service resulting in an expensive engine failure.

firstly to 14 Nm

then through 120

0

of nut rotation as measured

using the Triumph torque turn gauge

3880105-T0301.

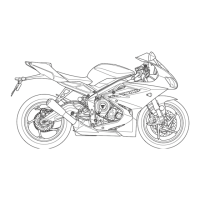

To accurately gauge the 120° turn, fit the tool

between the socket and the drive handle and

locate the socket to the big end nut. Pick an

increment point on the torque turn gauge which

aligns with a suitable reference point. Tighten the

bolts until 12 of the 10° gauge increments have

rotated past the chosen point.

Increment

marKing

^'^C.Ri^1ENZS

Service Tool 3880105-T0301

6.14

Loading...

Loading...