60C5D11

5-8

1

2

3

4

5

6

7

8

9

10. Measure the valve pad thickness with a

micrometer.

Select the necessary valve pad by calcu-

lating its thickness with the following for-

mula.

Example:

If the “Removed valve pad thickness” is 2.10

mm, the “Checked valve clearance” is 0.30

mm and the “Specified valve clearance” is

0.20 mm, then the necessary valve pad thick-

ness = 2.10 + 0.30 – 0.20 = 2.20 mm

11. Install the necessary valve pad into the

valve lifter.

12. Install the camshafts, camshaft caps,

driven sprockets, and timing belt, and

then tighten the tensioner bolt.

13. Check the valve clearance. Adjust if nec-

essary.

14. Loosen the tensioner bolt, and then

remove the timing belt and driven sprock-

ets.

15. Install the cylinder head cover and driven

sprockets.

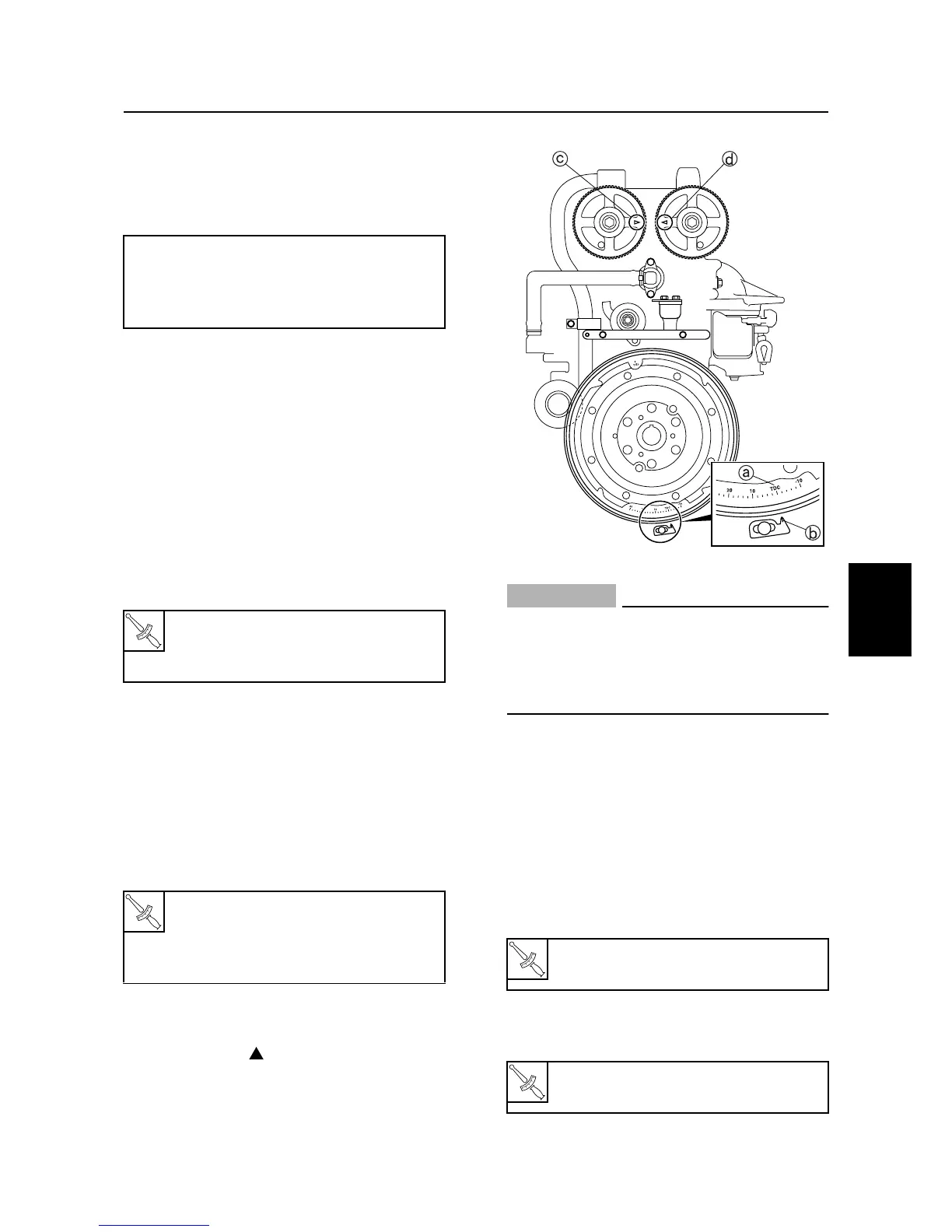

16. Check that the TDC mark

a

on the fly-

wheel magnet is aligned with the pointer

b

, and that “” marks

c

and

d

on the

driven sprockets are aligned. Adjust if

necessary.

CAUTION:

• Do not turn the flywheel magnet coun-

terclockwise, otherwise the valve sys-

tem may be damaged.

• Do not remove the ignition timing

pointer.

17. Install the timing belt, and then tighten

the tensioner bolt finger tight.

18. Turn the flywheel magnet clockwise two

turns, and then check that the alignment

marks are aligned.

19. Tighten the tensioner bolt to the specified

torque.

20. Install the spark plugs, and then connect

the high-tension cords and fuel hoses.

Necessary valve pad thickness =

Removed valve pad thickness + Measured

valve clearance – Specified valve

clearance

T

R

.

.

Camshaft cap bolt:

1st: 8 N·m (0.8 kgf·m, 5.8 ft·lb)

2nd: 17 N·m (1.7 kgf·m, 12 ft·lb)

T

R

.

.

Cylinder head cover:

8 N·m (0.8 kgf·m, 5.8 ft·lb)

Driven sprocket:

60 N·m (6.0 kgf·m, 43 ft·lb)

Loading...

Loading...