POWR

Power unit

5-31

60C5D11

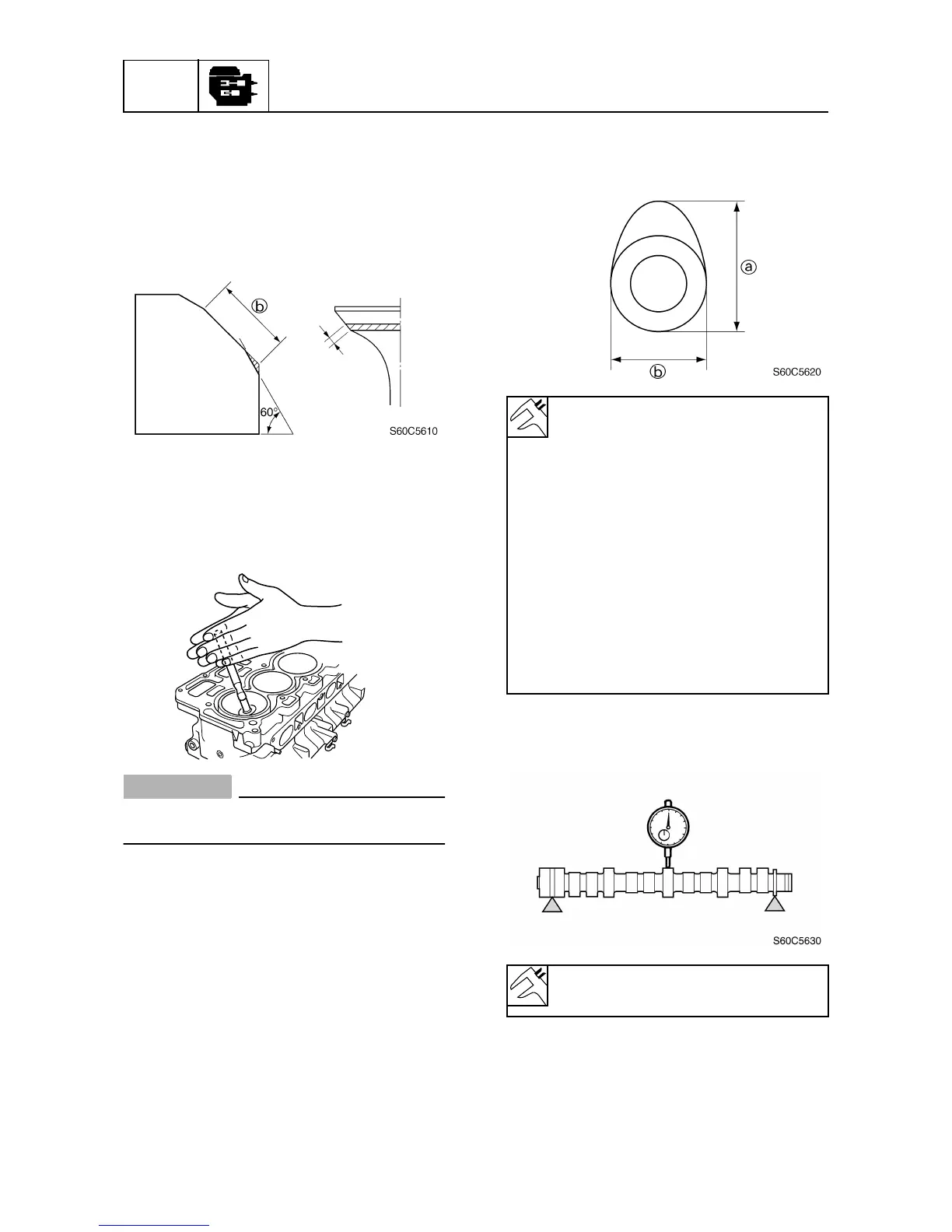

8. If the valve seat contact area is too nar-

row and situated near the bottom edge of

the valve face, use a 60° cutter to cut the

bottom edge of the valve seat. If neces-

sary, use a 45° cutter to center the area

and set its width.

b

Previous contact width

9. Apply a thin, even layer of lapping com-

pound onto the valve seat, and then lap

the valve using a valve lapper (commer-

cially obtainable).

CAUTION:

Do not get the lapping compound on the

valve stem and valve guide.

10. After every lapping procedure, be sure to

clean off any remaining lapping com-

pound from the cylinder head and the

valve.

11. Check the valve seat contact area of the

valve again.

Checking the camshaft

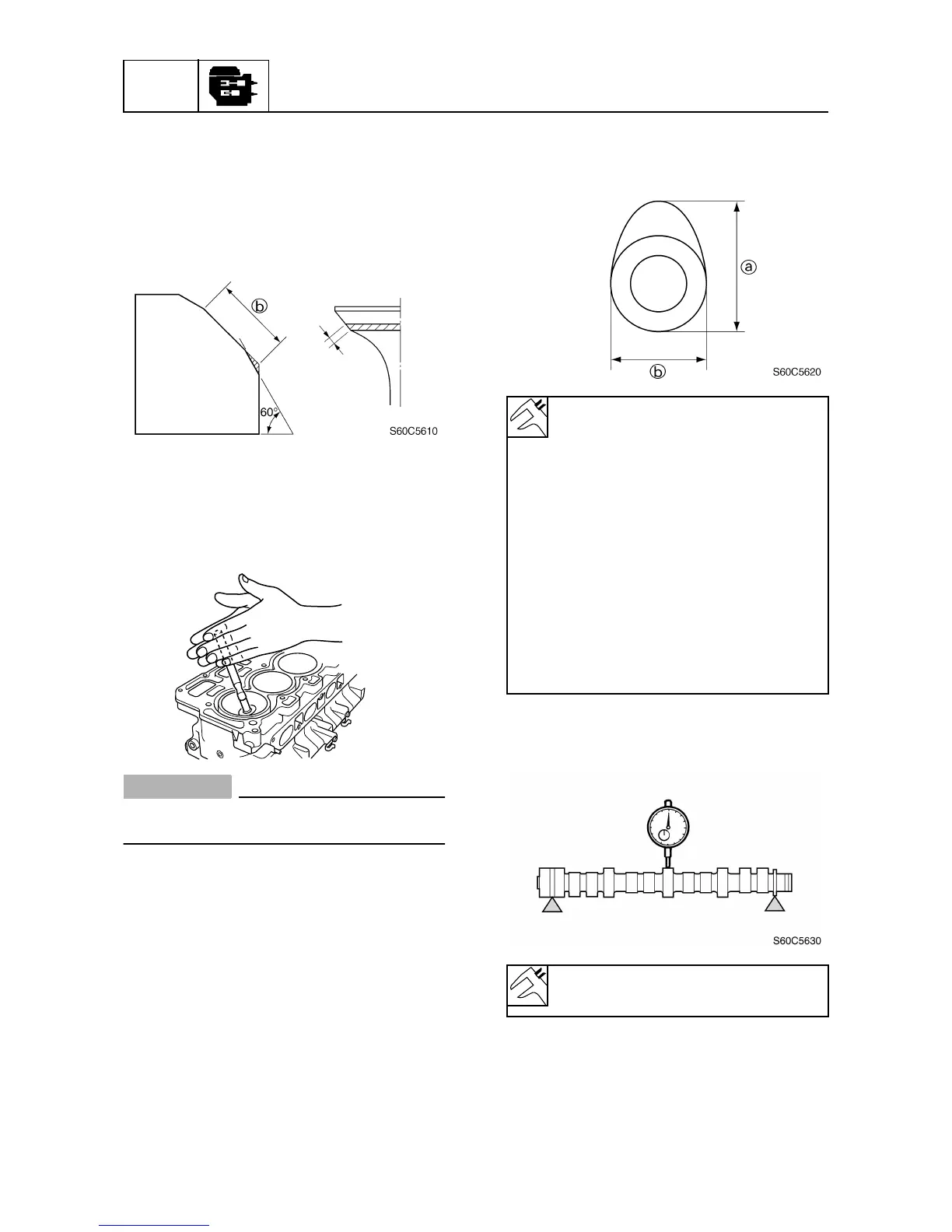

1. Measure the cam lobe. Replace if out of

specification.

2. Measure the camshaft runout. Replace if

out of specification.

S60C5500

Cam lobe

a:

Intake:

37.22–37.38 mm

(1.4654–1.4716 in)

Exhaust:

36.90–37.06 mm

(1.4528–1.4590 in)

Cam lobe b:

Intake:

29.92–30.08 mm

(1.1780–1.1842 in)

Exhaust:

29.92–30.08 mm

(1.1780–1.1842 in)

Camshaft runout limit:

0.1 mm (0.004 in)

Loading...

Loading...