MAINTENANCE

7-84

Check Track Sag (Steel Crawler) (Optional)

--- every 50 hours

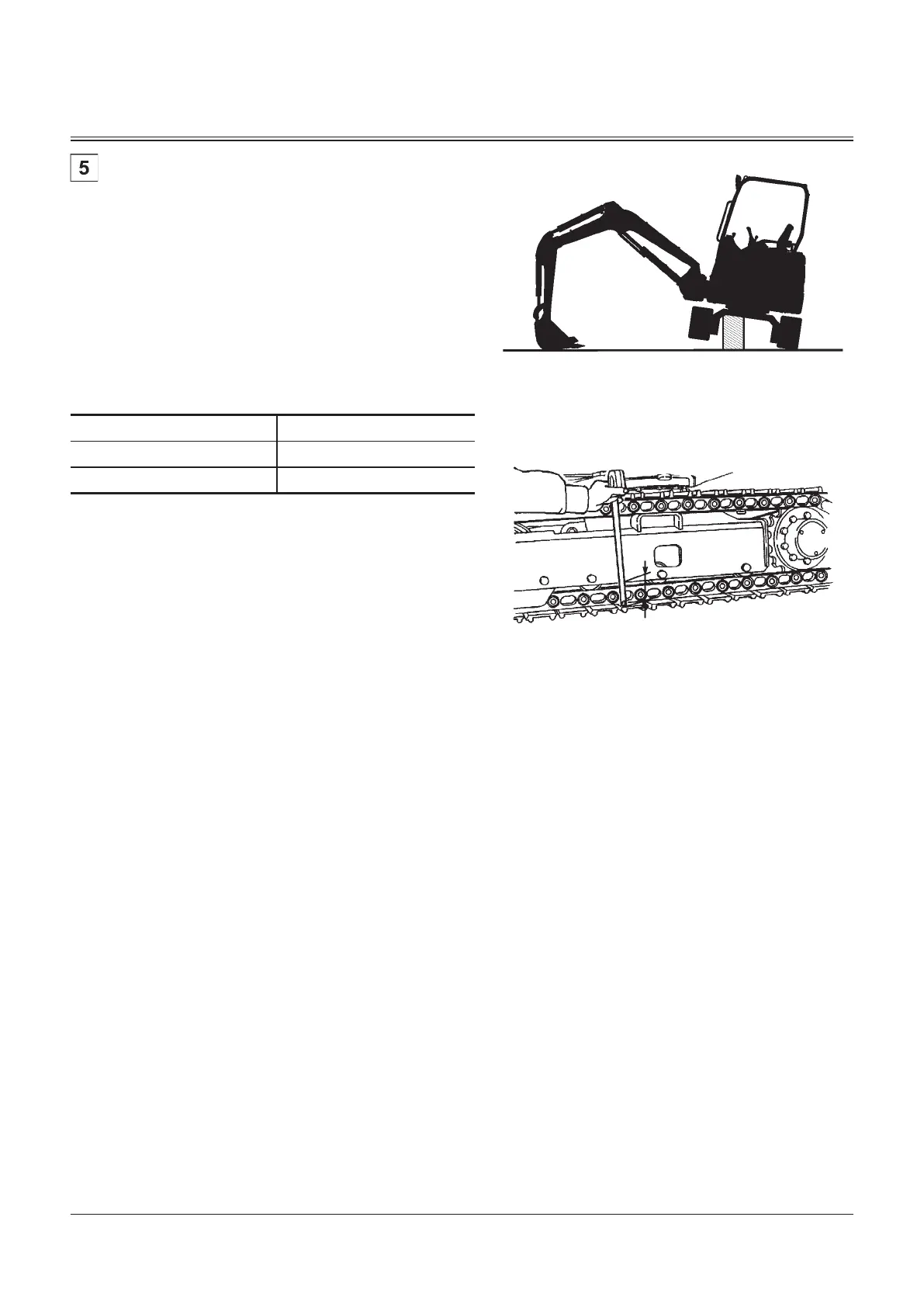

Swingtheupperstructure90°andlowerthebuckettoraise

thetrackoffthegroundasshown.Measuredistance(A)atthe

middleofthetrackframefromthebottomofthetrackframe

tothebackfaceofthetrackshoe.

Eachtime,besuretoplaceblocksunderthemachineframeto

support the machine.

d

CAUTION: To prevent accidents, care should be taken

to ensure that hands, feet, and any body parts do not

become entangled when working around the tracks.

Model Appropriate sag A (mm)

ZX30U-5N,35U-5N 120to140mm(4.7to5.5in)

ZX50U-5N,60USB-5N 140to160mm(5.5to6.3in)

f

NOTE: Check track sag after thoroughly removing soil stuck

on the track area by washing.

Adjust Track Sag

1. Iftracksagisnotwithinspecifications,loosenortighten

thetrackfollowingtheproceduresshownonthenext

page.

2. Whenadjustingtracksag,lowerthebuckettothe

groundtoraiseonetrackofftheground.Repeatthis

proceduretoraisetheothertrack.Eachtime,besureto

placeblocksunderthemachineframetosupportthe

machine.Topreventaccidents,careshouldbetaken

to ensure that hands, feet, and any body parts do not

becomeentangledwhenworkingaroundthetracks.

3. Afteradjustingbothsidetracksags,rotatethetracks

backwardandforwardtoequalizebothsidetracksags.

4. Recheckthetracksagoncemore.Readjustasnecessary.

M1M7-04-006

A

M588-07-062

Loading...

Loading...