13-2

HYDRAULIC BREAKER, HYDRAULIC CRUSHER AND QUICK COUPLER

OPTIONAL ATTACHMENT

Attachment

Allowable Weight Limits of Installed Attachment

d

WARNING:

When an attachment other than the standard bucket

is installed on the machine, the machine stability will

be different.

If a heavy attachment is used, not only will

controllability be affected but also machine stability

will be reduced, possibly causing safety hazard.

Before installing attachments such as hydraulic

breaker, crusher (concrete crusher), or pulverizer,

take machine controllability into account when

selecting the weight of the attachment by referring

to the table below.

According to the specifications of installed

attachment and the base machine, the machine

weight may exceed the allowable maximum

operating weight of the ROPS, making the ROPS

unable to assure the protective function for operator.

Refer to the ROPS certification affixed in the cab for

the allowable maximum operating weight.

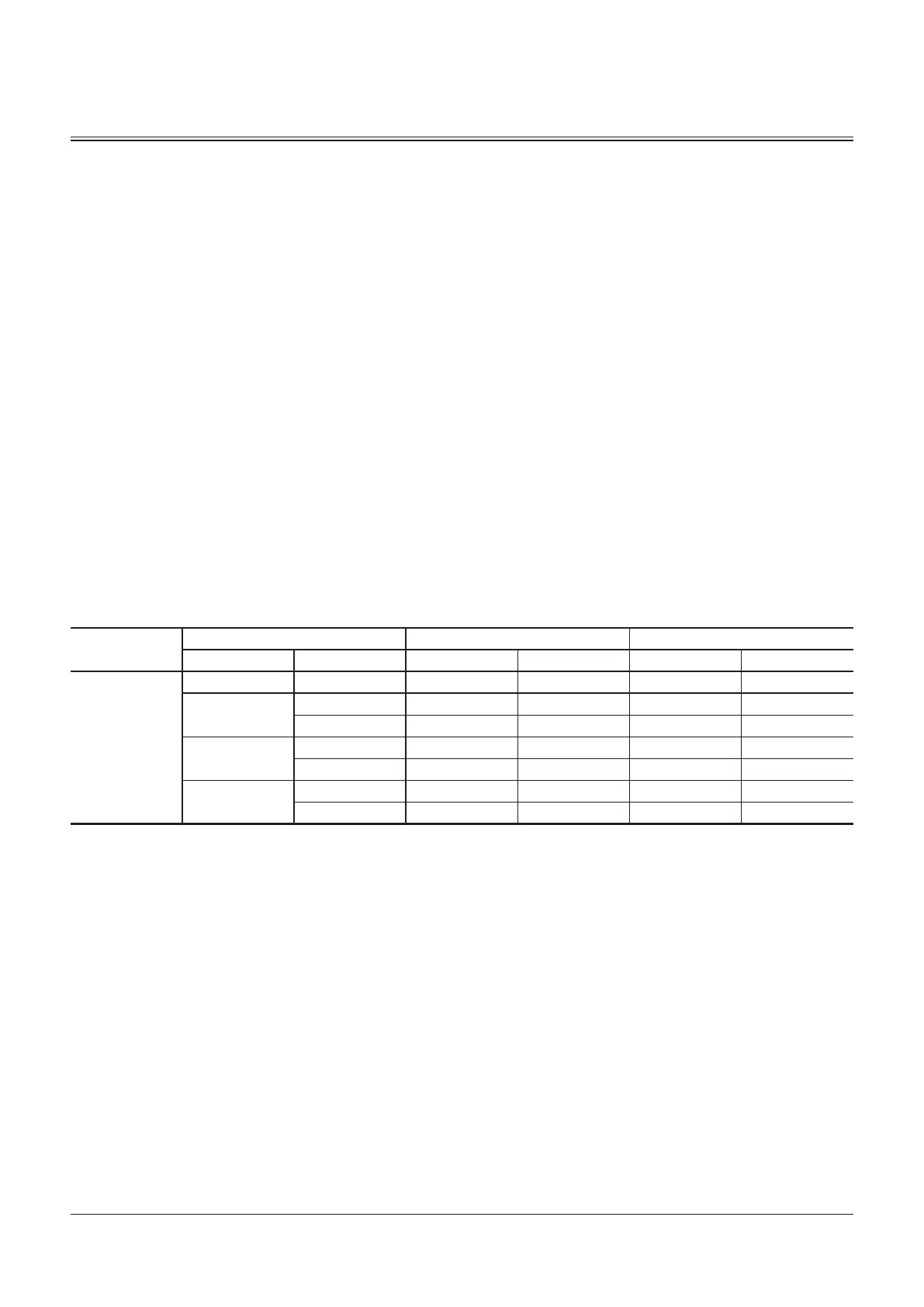

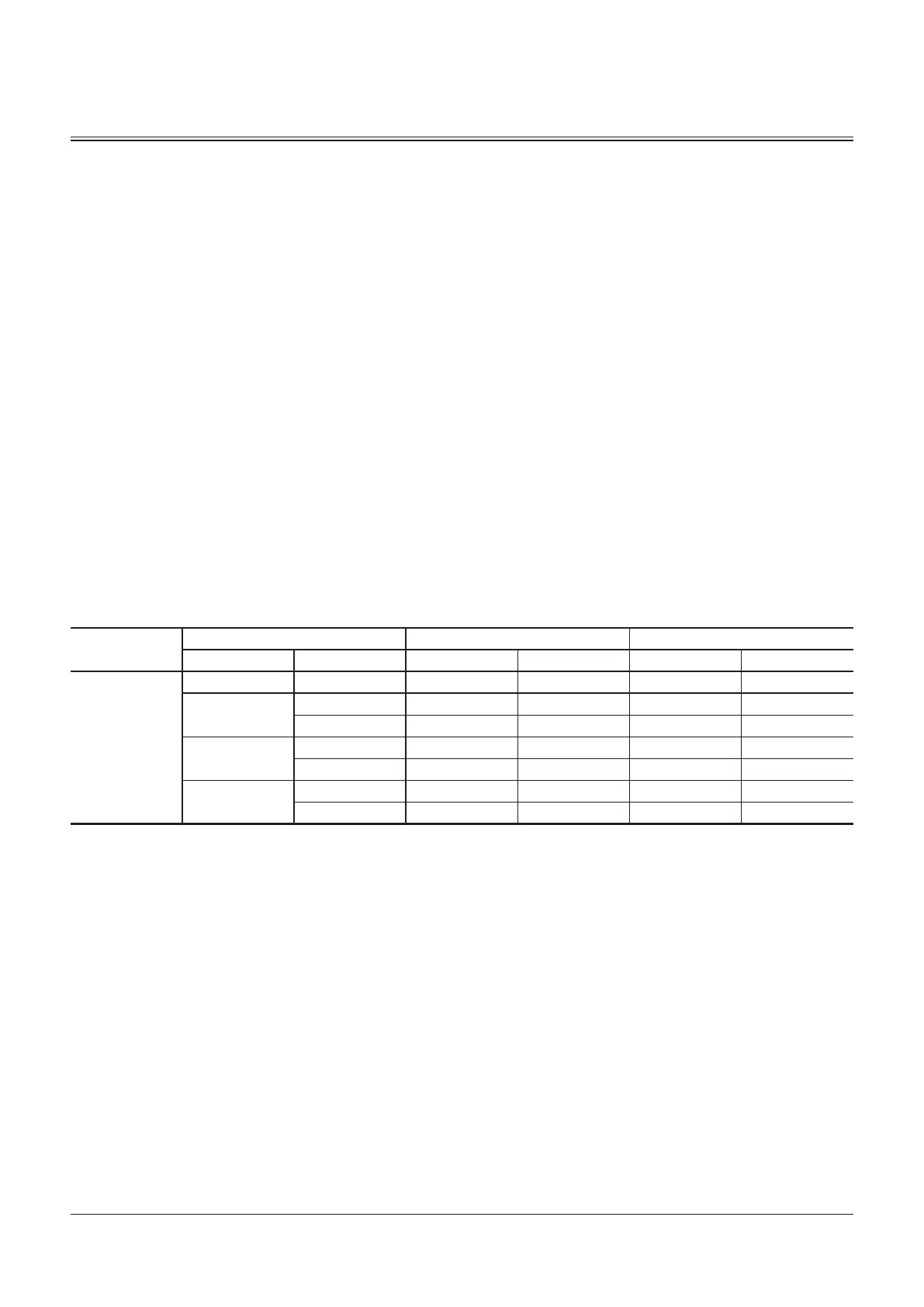

Specification

BaseMachine Breaker Crusher/Pulverizer

Model Arm Std.Weight Max.Weight Std.Weight Max.Weight

ZeroTailSwing

Model

ZX30U-5N Std. 200 220 240 280

ZX35U-5N

Std. 250 280 300 350

Long 220 240 260 300

ZX50U-5N

Std. 370 400 440 510

Long 330 360 400 460

ZX60USB-5N

Std. 460 500 550 640

Long 410 450 490 580

(without additional counterweight)

Breakeroperationspeedisfasterthancrusheroperation

sothattherecommendedbreakermax.weightsare

reduced more than those of the crushers.

Avoid installing an attachment with a long overall length.

Damagetothefrontattachmentmayresult.

Whenanattachmentofthemax.weightisinstalled,

always operate the attachment over the front or rear

side of the machine. In addition, avoid operating the

attachmentatthemaximumreach.

Crushersareheavierthanbreakers.Slowlymovethe

control lever when operating a crusher.

(Unit:kg)

Loading...

Loading...