Maintenance Guide

5-6

5-4 Replacing the AWC (Board Width Adjustment) Motor

1) Disconnect the motor relay cable connectors.

2) Loosen the screws (4 pcs.) of the AWC motor bracket to remove the timing belt from the

timing pulley.

3) Remove the screws (4 pcs.) of the motor to detach the motor.

4) Align the motor shaft end face of a new motor with the timing pulley, apply Loctite 243 to the

setscrews, and tighten them.

5) Secure the setscrews temporarily and adjust the timing belt tension to 25±2.5N・m by

moving up or down the motor.

Use UNITTA’s sonic belt tension meter (Weight=2.1, Width=9.5, Span=111) for the

adjustment.

6) After adjusted, tighten the screws to secure the motor.

Note) Tension is stretched excessively. → Torque of the drive shaft increases, causing the

motor bearing to break.

Note) Tension is loosened excessively. → Pulley teeth skip, causing noise, or worn-out or

broken timing belt.

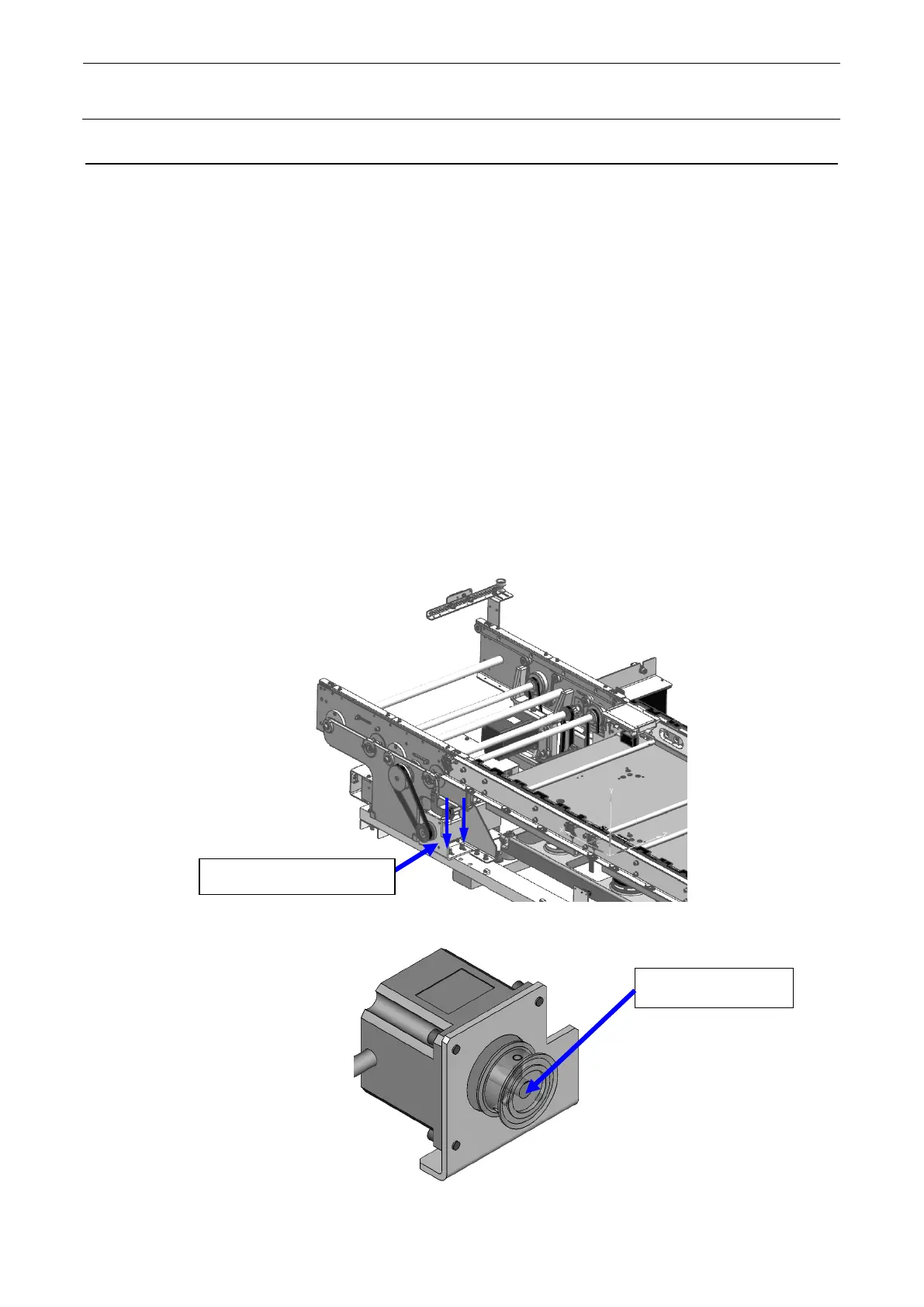

Figure 5-4-1 AWC Motor Bracket

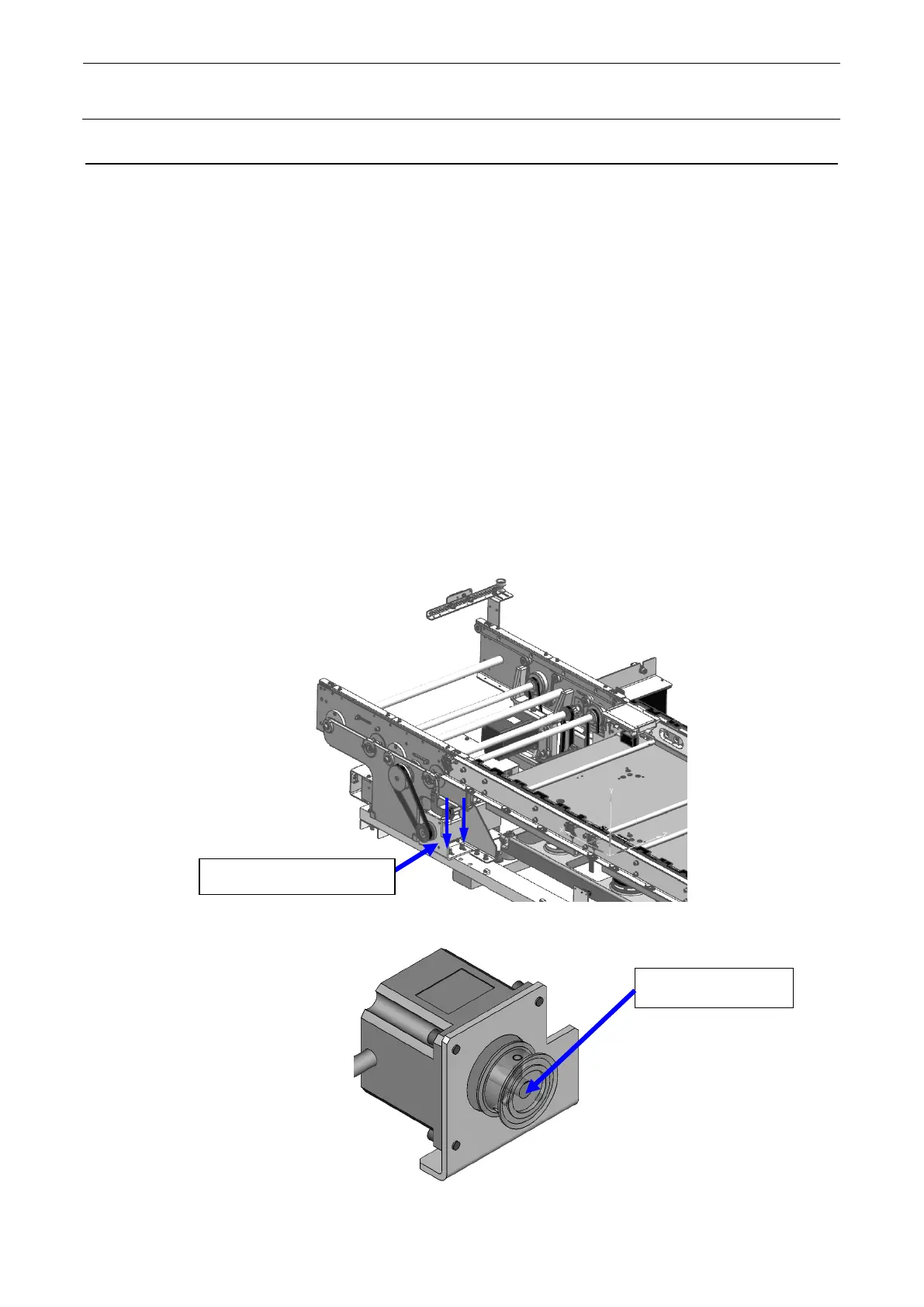

Figure 5-4-2 Motor and Timing Pulley

Align the end face.

Loading...

Loading...