16 ENGINE 118

300081-10

– Remove shift forks 2.

Info

Ensure that the pins remain in place.

300082-10

– Remove the lock ring 4 and the stop disk.

300083-10

– Pull both transmission shafts 5 out of the bearing seats together.

Info

The stop disk of the countershaft usually sticks to the bearing.

– Take the O-ring off the countershaft 6.

16.4 Work on individual parts

16.4.1 Work on the right section of the engine case

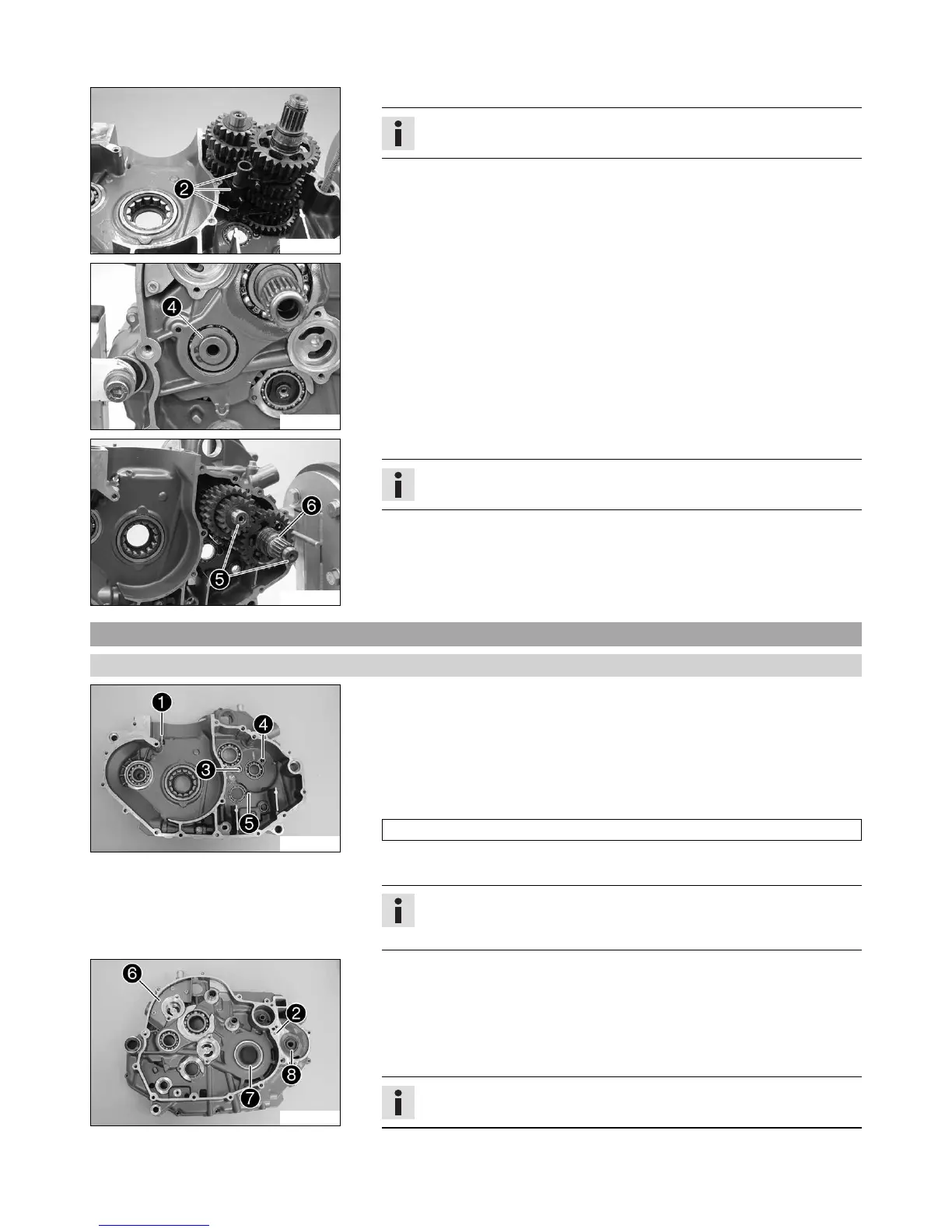

300094-10

– Remove oil jet 1.

– Remove bearing locks of the main shaft bearing 3, of the countershaft bearing 4,

and of the shift drum bearing 5.

– Remove any sealing mass remnants and clean the engine case section thoroughly.

– Pull the dowels out of the housing.

– Warm the engine case section in an oven.

Guideline

150 °C (302 °F)

– Knock the engine case section against a level wooden plate. This will cause the

bearings to drop out of the bearing seats.

Info

Any bearings that remain in the engine case section must be removed using

a suitable tool.

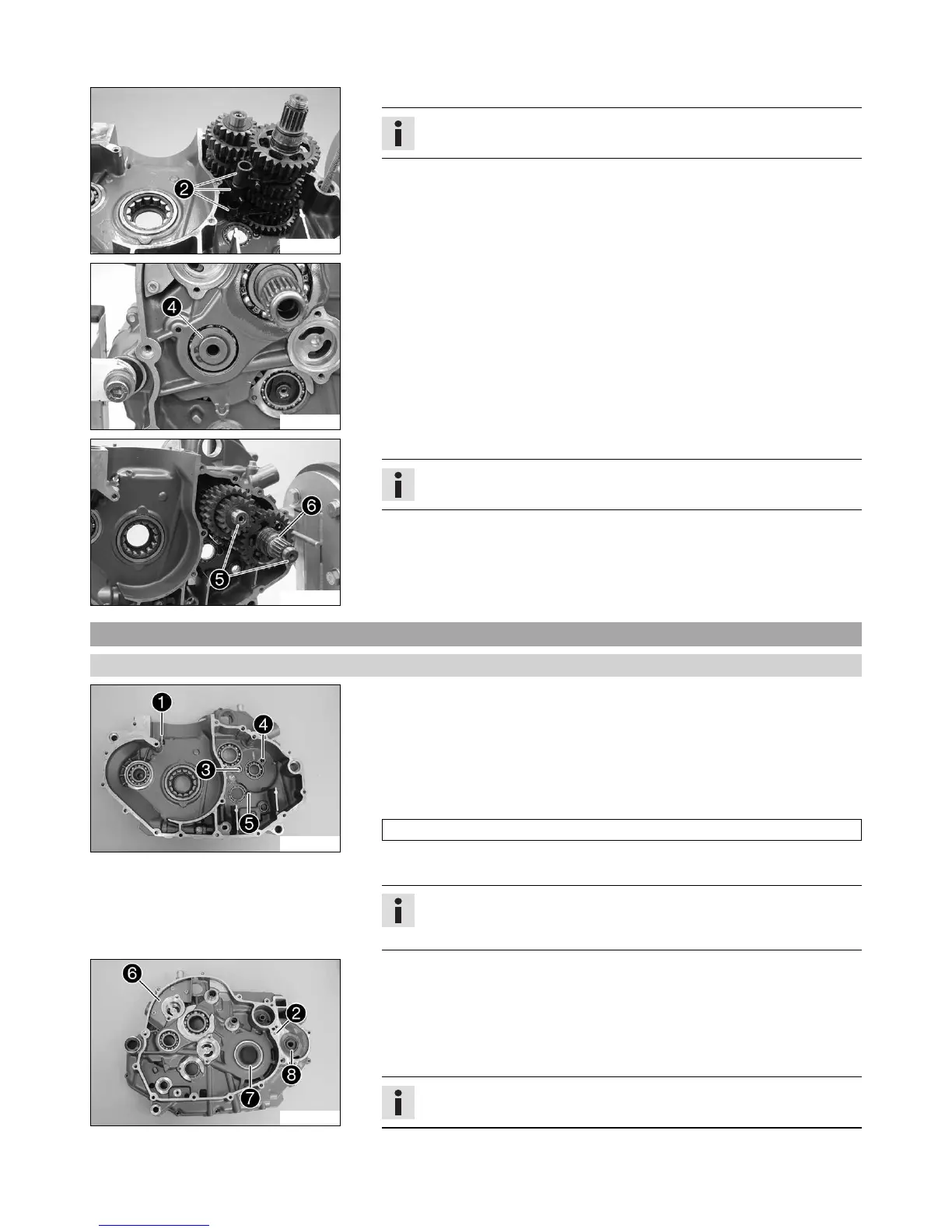

300095-10

– Remove oil jet 2.

– Remove the cover plate 6 for the oil return line.

– Press out the shaft seal ring 7 of the crankshaft from the inside to the outside.

– Remove the shaft seal rings 8 of the water pump.

– Press in the shaft seal ring 7 of the crankshaft from the outside to the inside with

the open side facing in.

Info

The shaft seal ring must be flush on the outside.

– Press in the shaft seal rings of the water pump with the open side facing out so

that it is flush.

Loading...

Loading...