16 ENGINE 121

– Mount and tighten screw A with the washer.

Guideline

Locking screw for bearing M5 6 Nm

(4.4 lbf ft)

Loctite

®

243™

– Press in the shaft seal ring of countershaft 2 and shift shaft 3 with the open side

facing inwards so that it is flush.

– Mount and tighten the oil jet 1.

Guideline

Oil jet, piston cooling M6x0.75 4 Nm

(3 lbf ft)

Loctite

®

243™

– Mount the dowels.

– Blow compressed air through all oil channels and check that they are clear.

200155-10

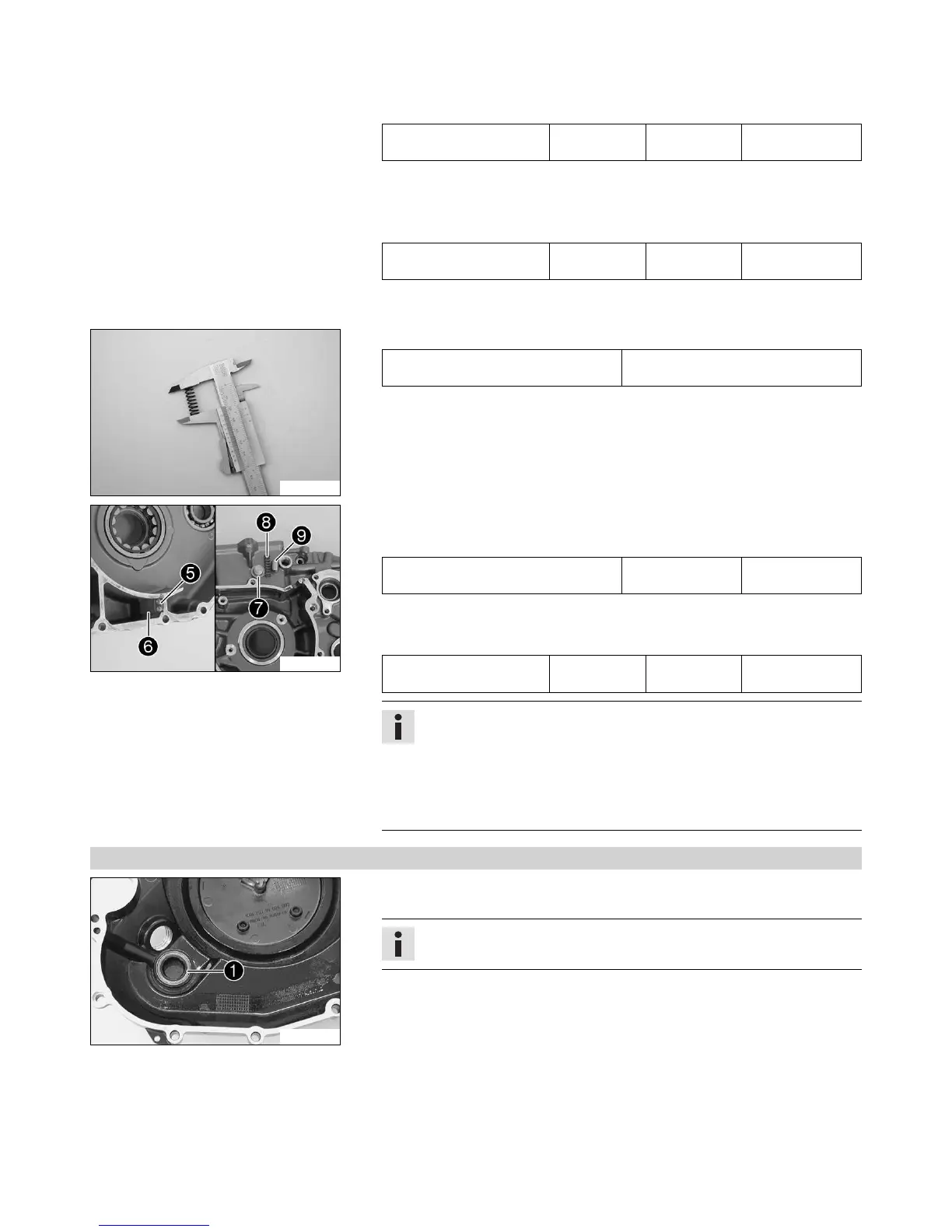

– Measure the spring length of the oil pressure regulator valve.

Oil pressure regulator valve - minimum

spring length

25.36 mm (0.9984 in)

» If the measured value does not equal the specified value:

– Change the spring.

– Check the piston valve for damage and wear.

» If there is damage or wear:

– Replace the piston valve.

300093-10

– Lubricate piston valve 9 and mount it with pressure spring 8. Mount and tighten

screw plug 7 with the new seal ring.

Guideline

Oil pressure regulator valve plug M12x1.5 20 Nm

(14.8 lbf ft)

– Position the membrane support plate 5 with membrane 6. Mount and tighten the

screws.

Guideline

Screw, membrane fixation M3 2 Nm

(1.5 lbf ft)

Loctite

®

243™

Info

The membrane support plate is curved and must point away from the mem-

brane.

An incorrectly installed membrane support plate results in loss of perfor-

mance and increased oil consumption or leaks.

Do not apply thread locker between the membrane and the membrane sup-

port plate since this would impair their function.

16.4.3 Work on the clutch cover

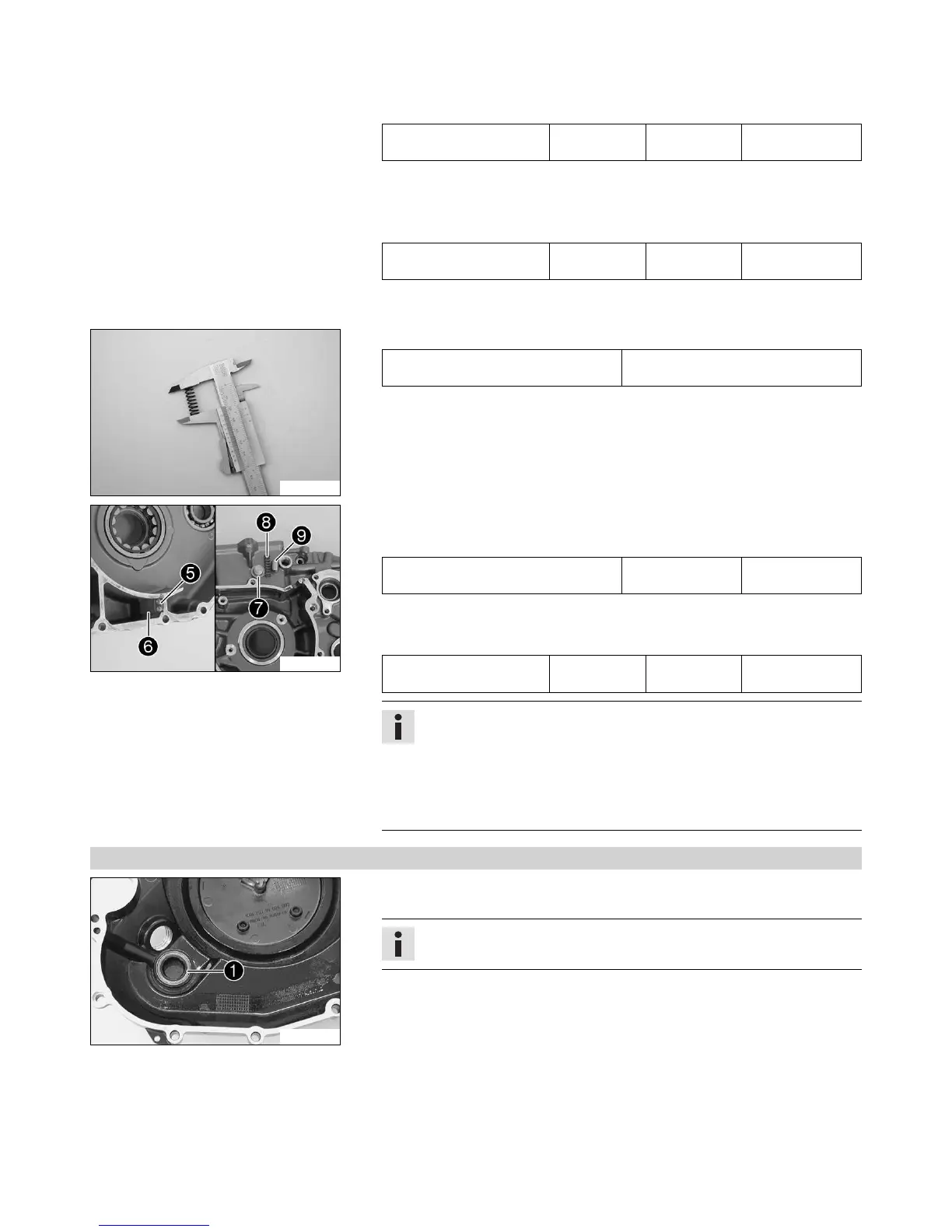

300097-10

– Remove the shaft seal ring 1 of the crankshaft.

– Press in a new shaft seal ring with the open side facing inward until it stops.

Info

Support the clutch cover sufficiently when pressing in.

– Blow compressed air through the oil channel and check that it is clear.

Loading...

Loading...