16 ENGINE 140

» If the sliding gear does not move easily:

– Change the sliding gear or the main shaft.

– Check sliding gears 5 for smooth operation in the profile of countershaft 3.

» If the fixed gear does not move easily:

– Change the sliding gear or the countershaft.

– Check stop disks 7 for damage and wear.

» If there is damage or wear:

– Change the stop disk.

– Use new lock rings 8 in every repair job.

– Check bearing bushes 9 for damage and wear.

» If there is damage or wear:

– Change the bearing bush.

16.4.37 Assembling the main shaft

Info

Use new lock rings in every repair job.

Preparatory work

– Oil all parts carefully before assembling.

– Check the transmission. ( p. 139)

Main work

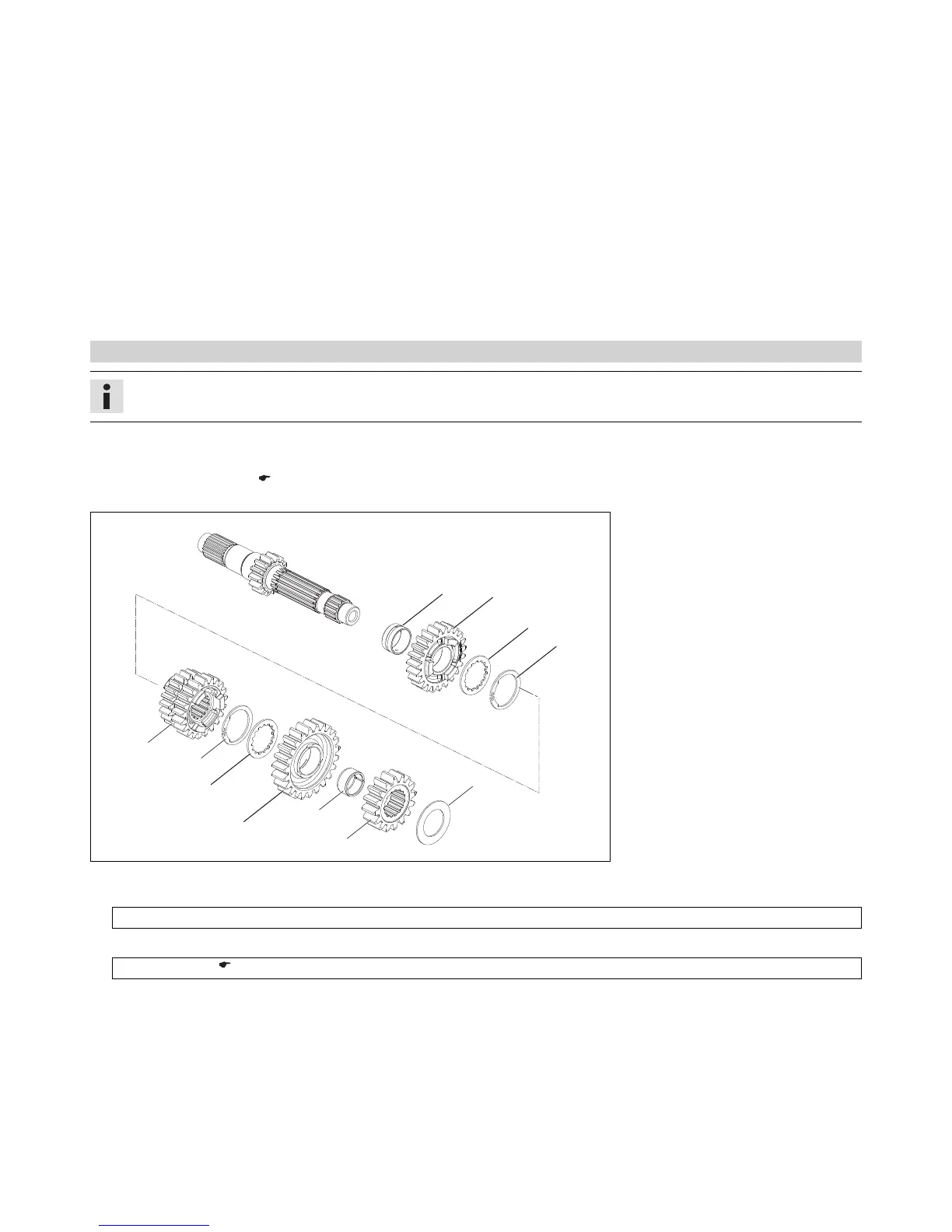

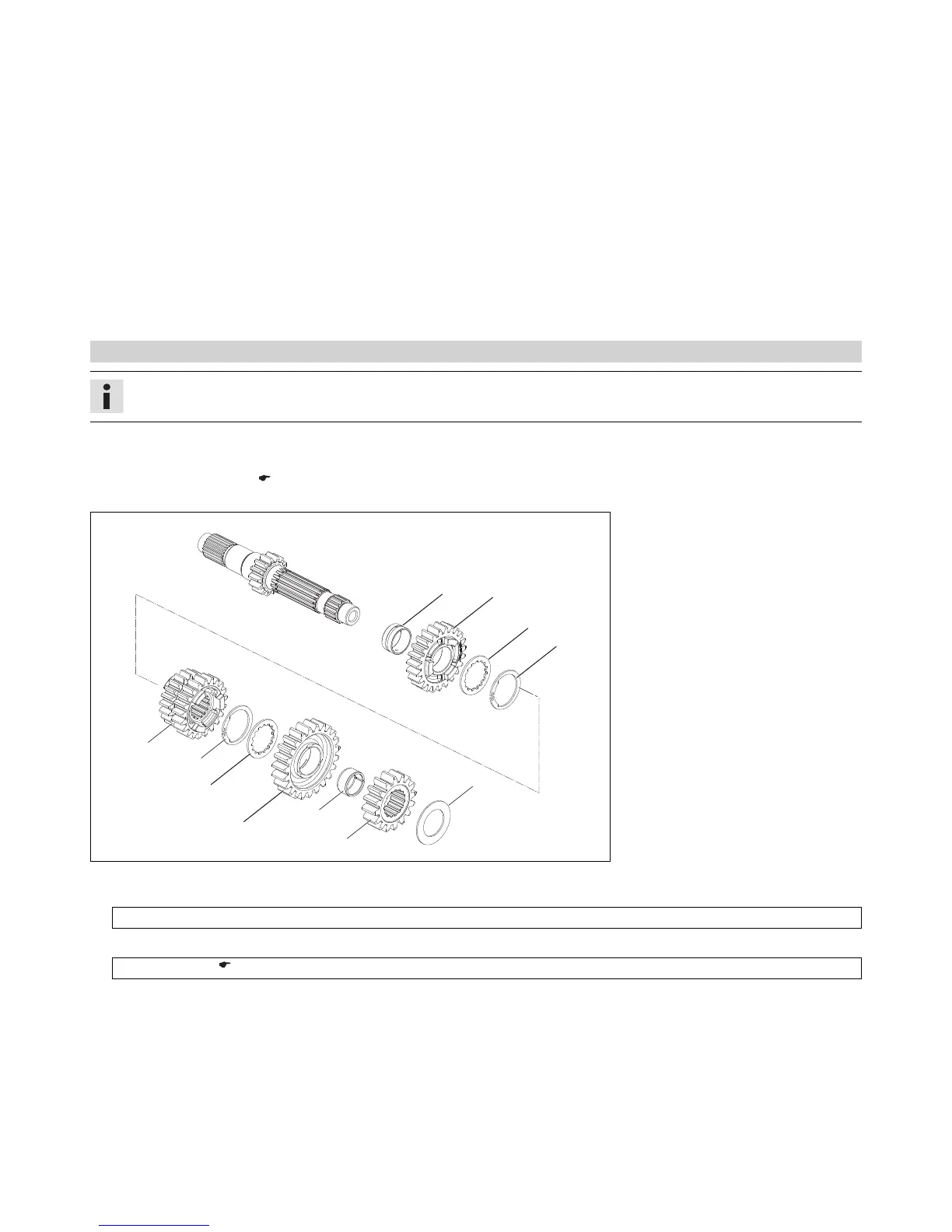

301980-02

– Fix the main shaft in the vise with the geared end facing downward.

Guideline

Use soft jaws

– Lubricate and mount bearing bush 1.

Long-life grease ( p. 208)

– Push on the fifth-gear idler gear 2 with the shift dogs facing upward.

– Mount stop disk 3 and lock ring 4.

– Push on the third/fourth-gear sliding gear 5 with the small gear wheel facing downward and mount lock ring 6.

– Push on stop disk 7 and split needle bearing 8.

– Push on the sixth-gear idler gear 9 with the shift dogs facing downward.

– Push on the second-gear fixed gear bk with the collar facing downward and mount stop disk bl.

– Finally, check all gear wheels for smooth operation.

Loading...

Loading...