16 ENGINE 136

– Check clutch facing discs bk for discoloration and scoring.

» If there is discoloration or scoring:

– Change all clutch facing discs.

– Check the thickness of clutch facing discs bk.

Clutch facing disc - thickness ≥ 2.5 mm (≥ 0.098 in)

» If the clutch facing disc does not meet specifications:

– Change all clutch facing discs.

– Check stepped washer bl for damage and wear.

» If there is damage or wear:

– Replace the stepped washer.

– Check half washers bm for damage and wear.

» If there is damage or wear:

– Replace the half washers.

– Check inner clutch hub bn for damage and wear.

» If there is damage or wear:

– Replace the inner clutch hub.

– Check the outer clutch hub bo for damage and wear.

» If there is damage or wear:

– Replace the outer clutch hub.

Finishing work

– Preassemble the antihopping clutch. ( p. 136)

16.4.31 Preassembling the antihopping clutch

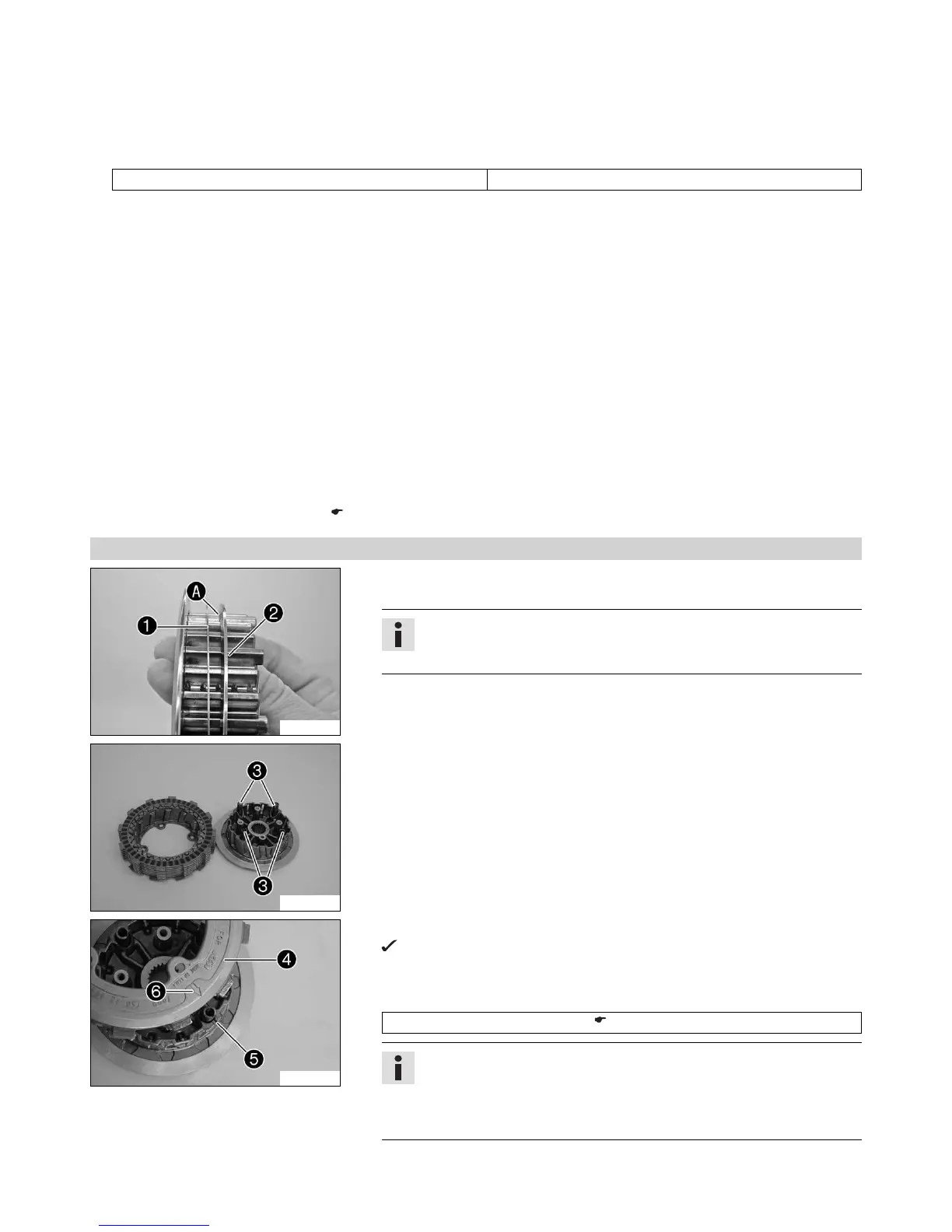

300123-10

– Thoroughly oil the clutch facing discs.

– Push the support ring 1 and the pretension ring 2 on to the outer clutch hub.

Info

The pretension ring must be installed so that it is flush with the inner

edge A on the support ring.

300124-10

– Position the trimmed clutch facing disc with the recess for the pretension ring on

the outer clutch hub.

– Beginning with the coated intermediate clutch disc, position all further clutch fac-

ing discs and intermediate clutch discs alternately.

– Position the release springs 3.

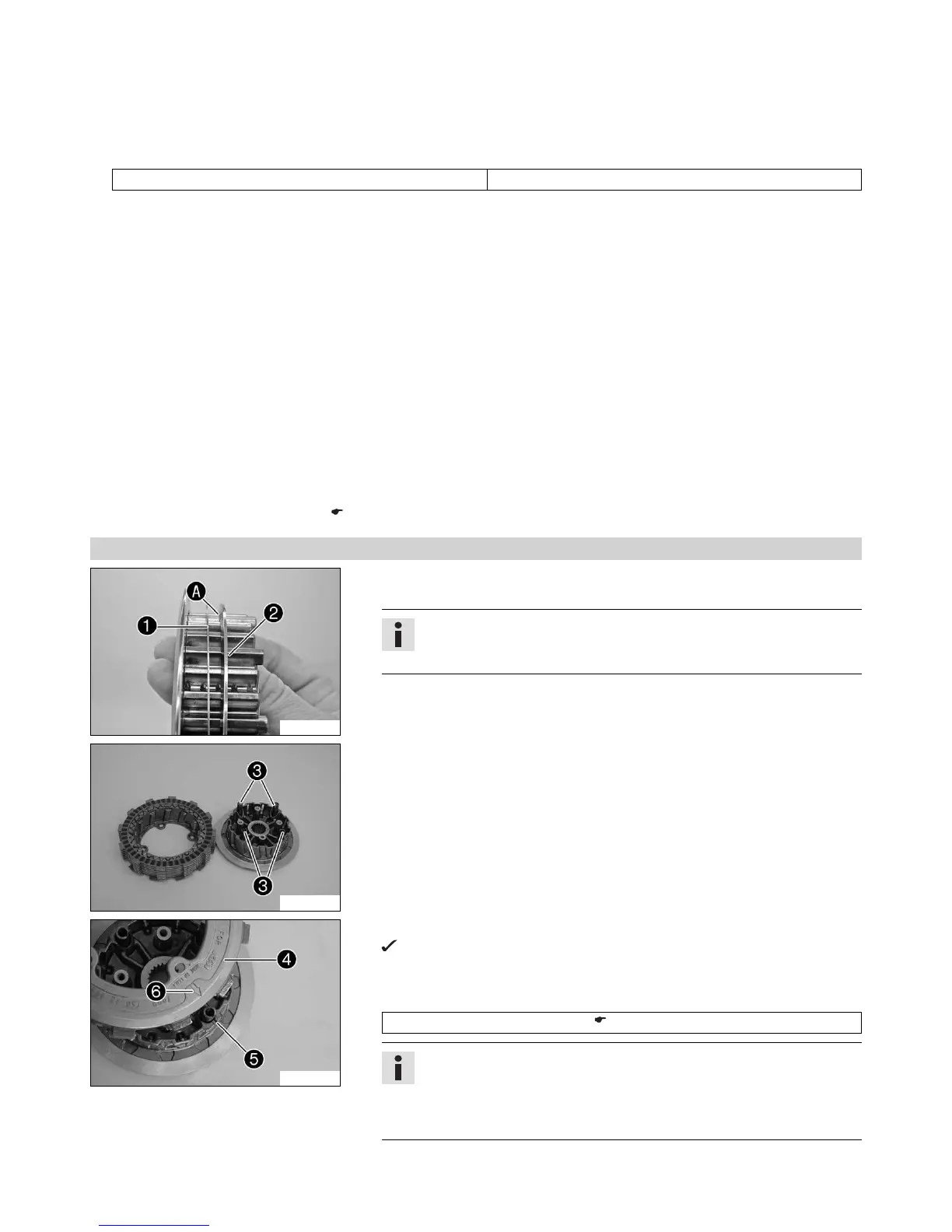

300125-10

– Push on the outer clutch hub 4 and pay attention to the markings.

The arrow 6 of the outer clutch hub must point to the notch 5 of the inner

clutch hub.

– Push the two clutch hubs firmly together and have an assistant screw in the special

tool.

Assembly screws (75029033000) ( p. 215)

Info

Apply the special tool with the hand only, do not use another tool.

Apply the special tool only firmly enough so that the clutch facing discs

can still be turned against each other since they still have to be aligned for

mounting in the clutch basket.

Loading...

Loading...