16 ENGINE 124

– Install the crankshaft bearing inner ring. ( p. 124)

– Measure the axial clearance of the crankshaft and the balancer shaft. ( p. 125)

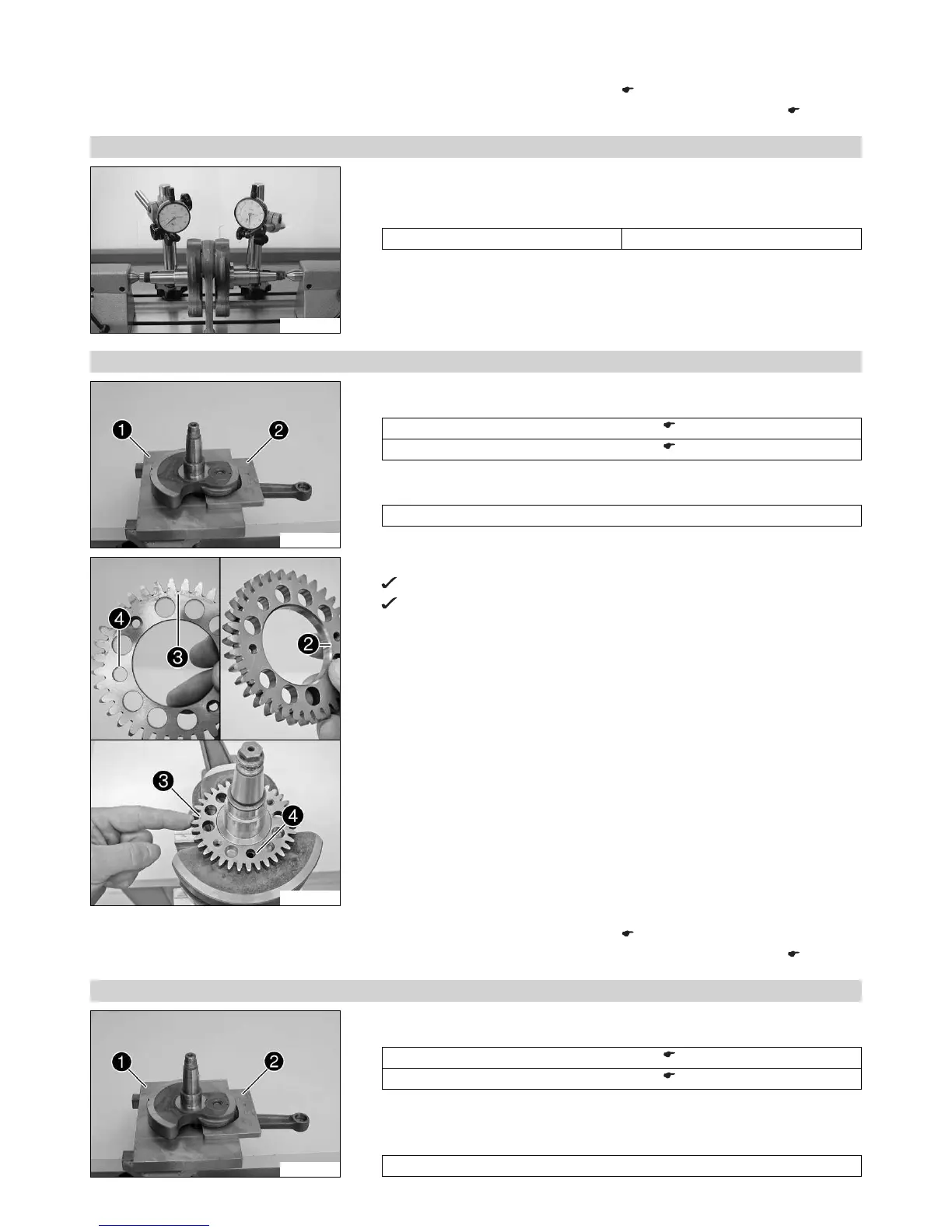

16.4.7 Checking crankshaft run-out at bearing pin

300132-10

– Position the crankshaft on a roller block.

– Rotate the crankshaft slowly.

– Check the crankshaft run-out at both bearing pins.

Crankshaft run-out at bearing pin ≤ 0.10 mm (≤ 0.0039 in)

» If the crankshaft run-out at the bearing pin is greater than the specified value:

– Align the crankshaft.

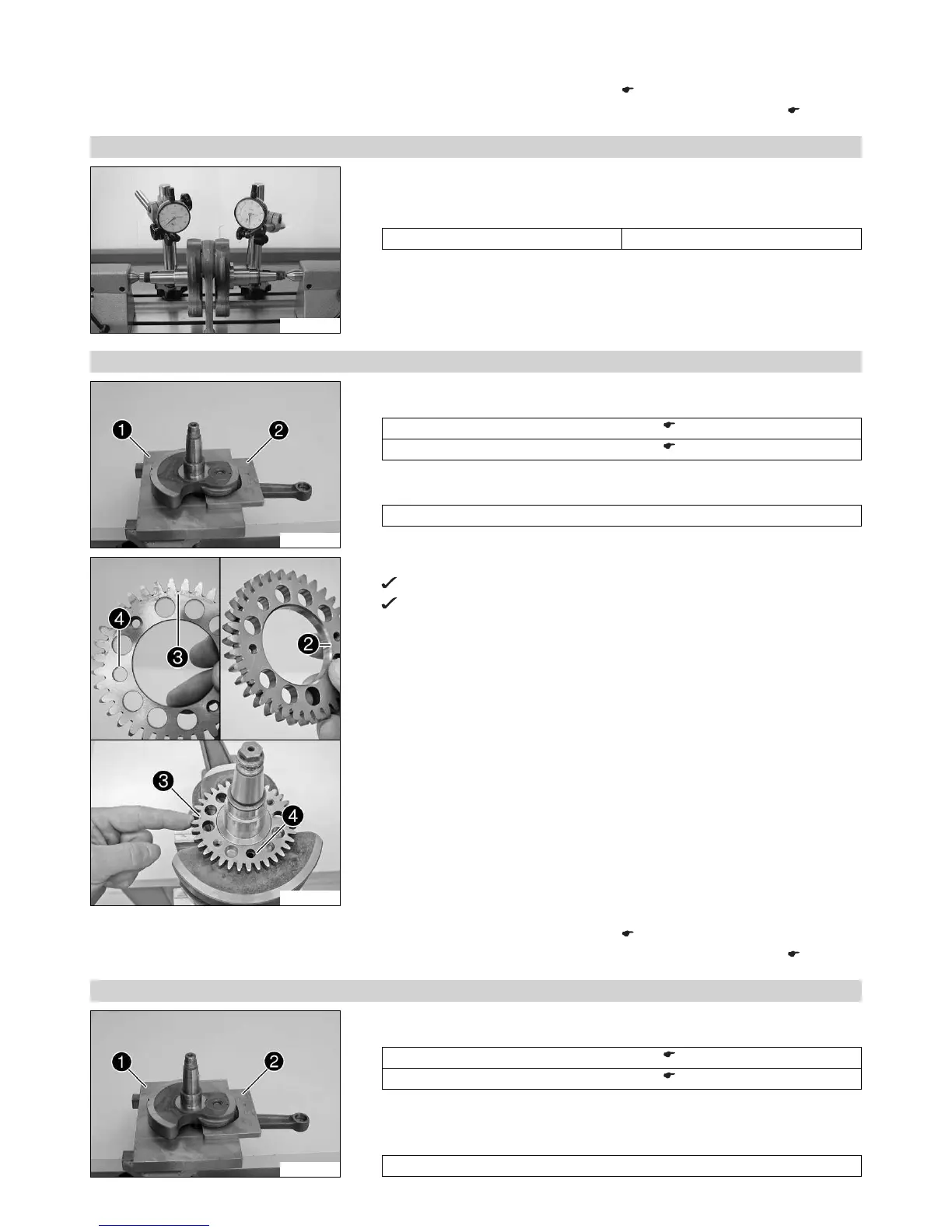

16.4.8 Installing balancer shaft drive wheel

302148-10

Main work

– Fix the crankshaft with special tools 1 and 2 in the vise.

Upper part, pressing-out tool (75029047050) ( p. 216)

Under part, pressing-out tool (75029047051) ( p. 216)

– Warm the drive wheel.

Guideline

100 °C (212 °F)

300159-10

– Place the drive wheel on the crankshaft.

The dowel of the crankshaft must fit in the drill hole 4.

The side of the drive wheel with the punch mark 3 must be visible after

assembly, and the side with the bevel 2 must be in contact with the

crankweb.

Finishing work

– Install the crankshaft bearing inner ring. ( p. 124)

– Measure the axial clearance of the crankshaft and the balancer shaft. ( p. 125)

16.4.9 Installing crankshaft bearing inner ring

302150-10

Main work

– Fix the crankshaft with special tools 1 and 2 in the vise.

Upper part, pressing-out tool (75029047050) ( p. 216)

Under part, pressing-out tool (75029047051) ( p. 216)

– Push on the compensation shim.

– Heat the special tool. Install the inner bearing race.

Guideline

120 °C (248 °F)

Loading...

Loading...