16 ENGINE 127

– Check the piston rings for damage.

» If the piston ring is damaged:

– Change the piston ring.

Info

Mount the piston ring with the marking facing upward.

– Check the piston pin for discoloration or signs of wear.

» If the piston pin has strong discoloration/signs of wear:

– Change the piston pin.

– Insert the piston pin into the connecting rod and check the bearing for play.

» If the piston pin bearing has too much play:

– Change the connecting rod and the piston pin.

302138-10

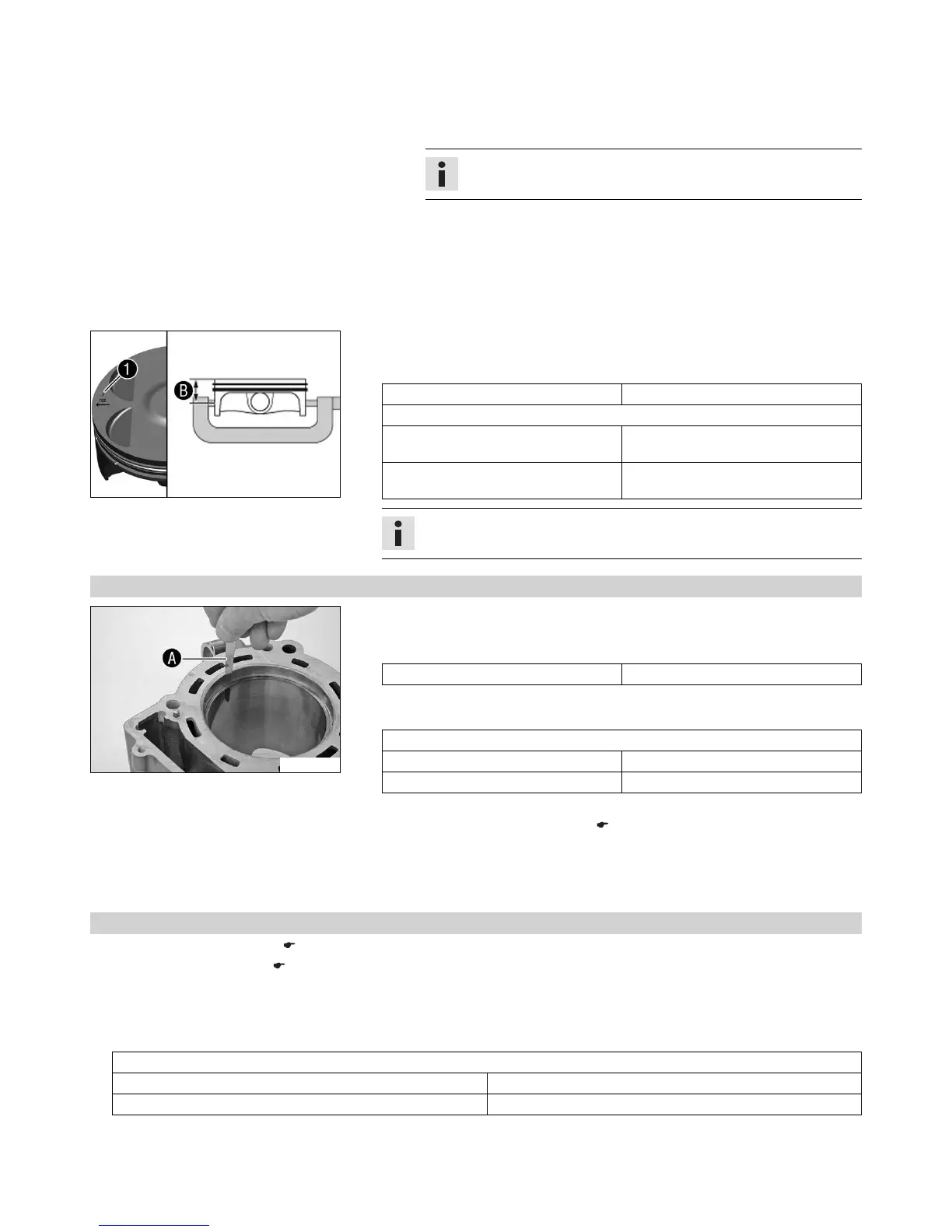

– Measure the piston at the piston skirt, at right angles to the piston pin, at a

distance B.

Guideline

Distance B 31.5 mm (1.24 in)

Piston - diameter

Size I 101.955… 101.965 mm (4.01397…

4.01436 in)

Size II 101.965… 101.975 mm (4.01436…

4.01476 in)

Info

Piston size 1 is marked on the piston head.

16.4.14 Checking piston ring end gap

300098-10

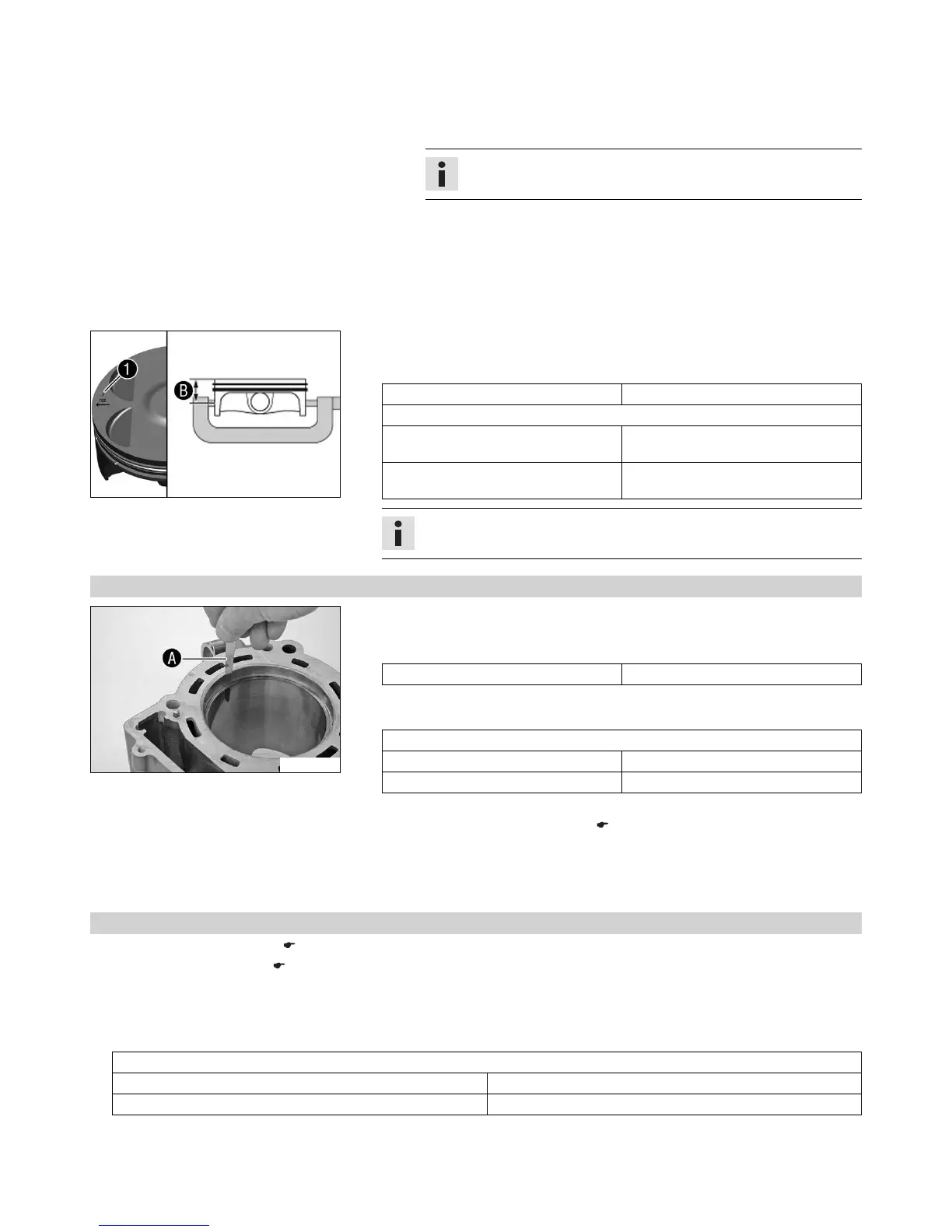

– Remove the piston ring from the piston.

– Place the piston ring in the cylinder and align it with the piston.

Guideline

Under the upper edge of the cylinder 10 mm (0.39 in)

– Measure the end gap with a feeler gauge A.

Guideline

Piston ring end gap

Compression rings ≤ 0.80 mm (≤ 0.0315 in)

Oil scraper ring ≤ 1.00 mm (≤ 0.0394 in)

» If the end gap is more than the specified value:

– Check/measure the cylinder. ( p. 126)

» If the cylinder wear is within the tolerance range:

– Change the piston ring.

– Mount the piston ring with the marking facing toward the piston head.

16.4.15 Checking piston/cylinder mounting clearance

– Check/measure the cylinder. ( p. 126)

– Check/measure the piston. ( p. 126)

– The smallest piston/cylinder mounting clearance is the result of the smallest cylinder bore diameter minus the largest piston diam-

eter. The largest piston/cylinder mounting clearance is the result of the largest cylinder bore diameter minus the smallest piston

diameter.

Guideline

Piston/cylinder - mounting clearance

New condition 0.035… 0.060 mm (0.00138… 0.00236 in)

Wear limit 0.10 mm (0.0039 in)

Loading...

Loading...