ENGINE

B2301, B2601, WSM

1-S32

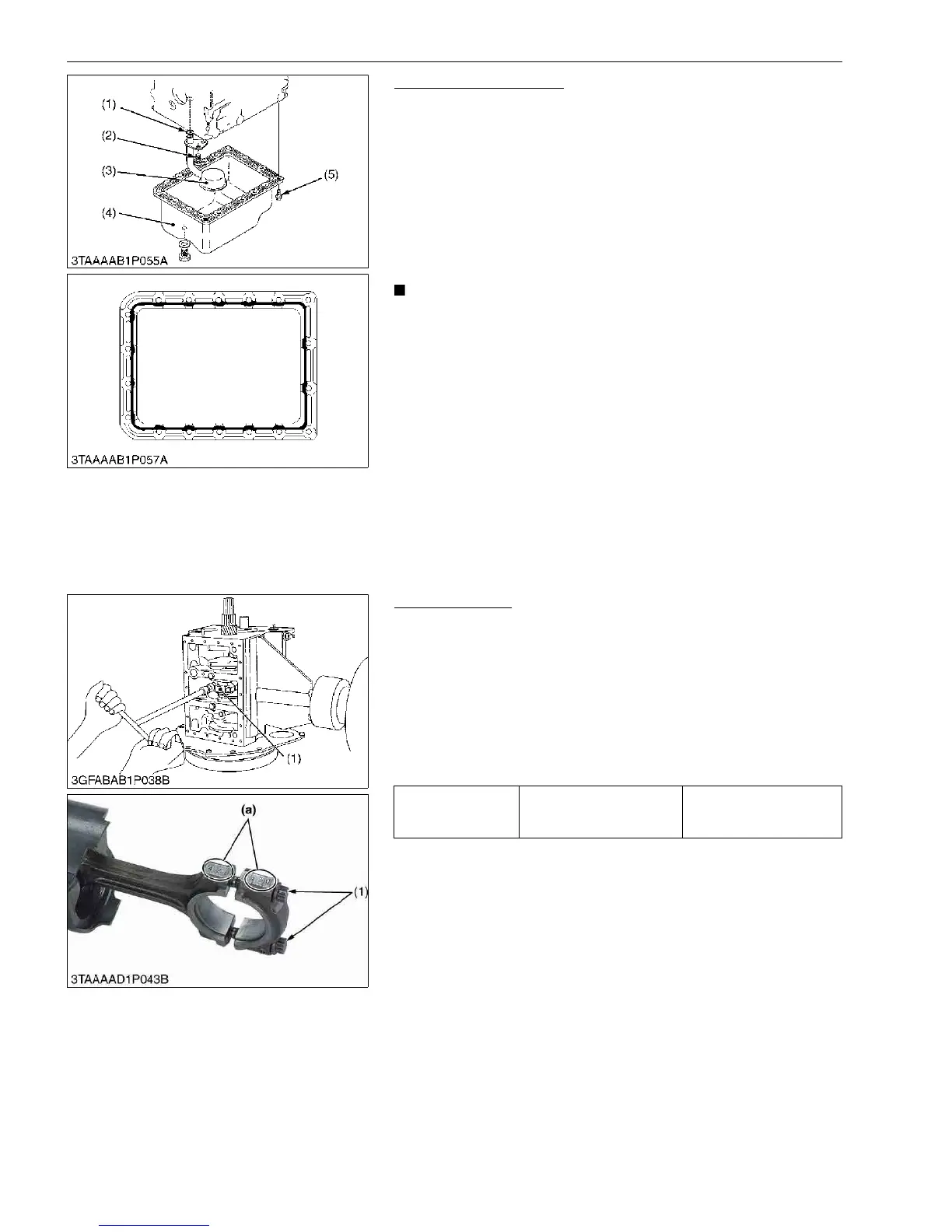

Oil Pan and Oil Strainer

1. Remove the oil pan mounting screws (5).

2. Remove the oil pan (4).

3. Remove the oil strainer (3).

(When reassembling)

• After cleaning the oil strainer, check to see that the filter mesh

is clean, and install it.

• Visually check the O-ring (1), apply engine oil, and install it.

• Securely fit the O-ring to the oil strain.

• To avoid uneven tightening, tighten oil pan mounting screws in

diagonal order from the center.

• Scrape off the old adhesive completely. Wipe the sealing

surface clean using waste cloth soaked with gasoline. Now

apply new adhesive 3 to 5 mm (0.12 to 0.20 in.) thick all over

the contact surface. Apply the adhesive also on the center

of the flange as well as on the inner wall of each screw hole.

• Cut the nozzle of the "liquid gasket" container at its second

notch. Apply "liquid gasket" about 5 mm (0.2 in.) thick.

Within 20 minutes after the application of fluid sealant,

reassemble the components. Wait then for about 30

minutes, and pour oil in the crankcase.

9Y1211156ENS0046US0

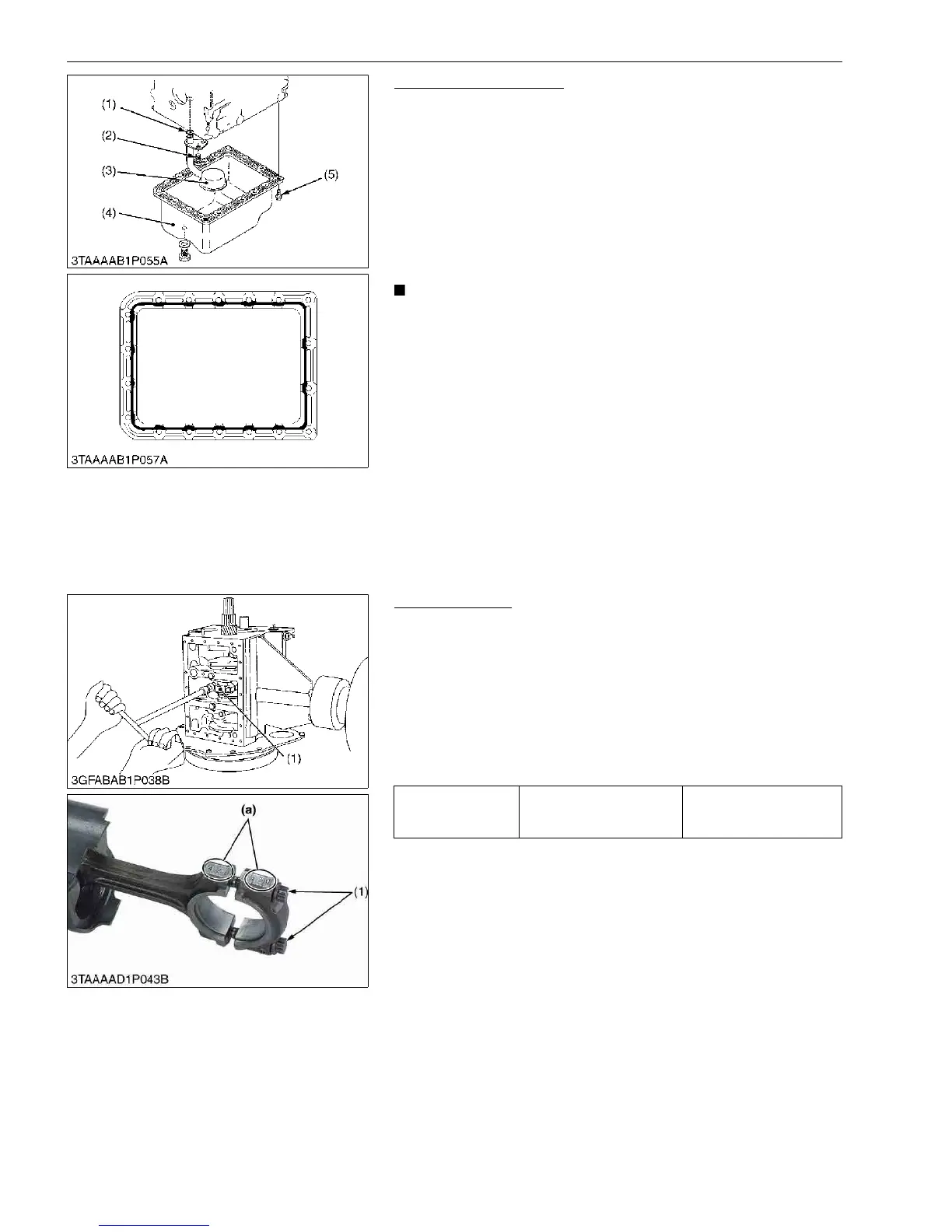

(4) Piston and Connecting Rod

Connecting Rod

1. Remove the connecting rod cap.

(When reassembling)

• Align the marks (a) with each other. (Face the marks toward the

injection pump.)

• Apply engine oil to the connecting rod screws (1) and lightly

screw it in by hand, then tighten it to the specified torque.

If the connecting rod screw won't be screwed in smoothly, clean

the threads.

If the connecting rod screw (1) is still hard to screw in, replace it.

9Y1211156ENS0047US0

(1) O-ring

(2) Screw

(3) Oil Strainer

(4) Oil Pan

(5) Oil Pan Mounting Screws

Tightening torque Connecting rod screw

42 to 46 N·m

4.2 to 4.7 kgf·m

31 to 33 lbf·ft

(1) Connecting Rod Screw (a) Mark

Loading...

Loading...